Converter Continuous Casting Square Steel Billet Q235 Q275 Q345 for Construction

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

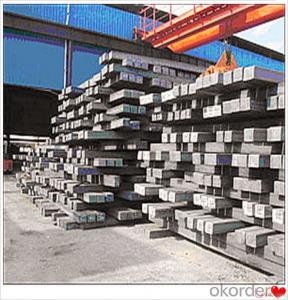

Converter Continuous Casting Square Steel Billet Q235 Q275 Q345 for Construction

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q:Are steel billets used in the production of electrical appliances?

- Yes, steel billets are commonly used in the production of electrical appliances. Steel is a versatile material that offers several advantages such as strength, durability, and resistance to corrosion. It is widely used in the manufacturing of various components of electrical appliances, including the outer casing, frames, and internal structural supports. Steel billets are an intermediate product in the steel manufacturing process and can be further processed into different shapes and sizes to meet the specific requirements of electrical appliance production.

- Q:What are the different methods used for heating steel billets?

- There are several methods used for heating steel billets including induction heating, flame heating, and electric resistance heating.

- Q:Can steel billets be used in the production of industrial equipment?

- Industrial equipment can indeed utilize steel billets. These semi-finished metal products can undergo further processing to produce a wide range of industrial equipment, including machinery, tools, automotive parts, construction materials, and more. Steel's exceptional strength, durability, and adaptability make it the perfect material for manufacturing industrial equipment. By shaping, machining, and welding steel billets, intricate structures and components can be created, ensuring the necessary strength and stability for industrial applications. Furthermore, heat treatment can be applied to steel billets to enhance their mechanical properties, making them even more suitable for heavy-duty industrial equipment.

- Q:Can steel billets be used in the production of medical equipment?

- Yes, steel billets can be used in the production of medical equipment. Steel is commonly used in the manufacturing of medical devices and equipment due to its strength, durability, and resistance to corrosion. Steel billets are often processed and shaped into specific components or parts required for medical equipment, such as surgical instruments, implants, and diagnostic tools.

- Q:How do steel billets contribute to the manufacturing of rail and transportation systems?

- Steel billets are an essential raw material in the manufacturing of rail and transportation systems. These billets serve as the starting point for the production of various components, such as rails, wheels, axles, and structural supports. Through a series of processes like rolling, forging, and machining, steel billets are transformed into these vital parts, which provide strength, durability, and stability to rail tracks, locomotives, and other transportation vehicles. In summary, steel billets are crucial in ensuring the reliability and safety of rail and transportation systems.

- Q:How are steel billets used in the production of gears?

- Steel billets are used in the production of gears as they serve as the raw material from which gears are forged or machined. Steel billets undergo a series of processes such as heating, shaping, and cutting to transform them into the desired gear shape. The billets are carefully crafted and shaped to ensure the highest quality and durability of the gears, allowing them to effectively transmit power and perform their intended function in various machinery and equipment.

- Q:What are the common challenges in steel billet production?

- There are several common challenges in steel billet production that manufacturers often face. One of the primary challenges is maintaining consistent quality throughout the production process. Steel billets need to meet specific standards and specifications in terms of chemical composition, mechanical properties, and surface finish. Any deviation from these requirements can lead to rejection of the billets, causing delays and additional costs. Therefore, ensuring consistent quality control throughout the production cycle is crucial. Another challenge is achieving the desired size and shape of the billets. Steel billets come in various sizes and shapes, depending on the intended use. Producing billets with accurate dimensions and shape requires precision and careful calibration of the equipment involved in the production process. Any deviation in size or shape can result in difficulties during downstream processes, such as rolling or forging, and may lead to product defects or inefficiencies. Maintaining efficient production rates is also a common challenge. Steel billet production often involves complex and time-consuming processes, such as melting, casting, and cooling. Any disruption or bottleneck in these processes can significantly impact the production rate and overall efficiency. It is crucial to optimize the production flow and identify and address any bottlenecks in order to meet demand and minimize production delays. Controlling energy consumption and minimizing waste is another challenge in steel billet production. The production of steel billets requires high energy inputs, such as electricity and fuel. Finding ways to reduce energy consumption and optimize the use of resources can help minimize production costs and environmental impact. Additionally, minimizing waste generation and implementing effective recycling or reusing strategies can further enhance the sustainability of the production process. Lastly, ensuring the safety of workers and maintaining a safe working environment is a critical challenge in steel billet production. The production process involves working with heavy machinery, high temperatures, and potentially hazardous materials. Implementing robust safety protocols, providing appropriate personal protective equipment, and conducting regular safety audits are essential to prevent accidents and ensure the well-being of the workforce. Overall, steel billet production faces challenges related to maintaining consistent quality, achieving accurate size and shape, maintaining efficient production rates, controlling energy consumption, and ensuring worker safety. Overcoming these challenges requires continuous improvement, investment in technology and equipment, and a commitment to quality control and safety measures.

- Q:How are steel billets used in the manufacturing of hydraulic cylinders?

- Steel billets are an essential component in the manufacturing of hydraulic cylinders. These billets, which are cylindrical shapes of raw steel, serve as the starting material for the production process. Hydraulic cylinders are widely used in various industries, such as construction, mining, and automotive, to provide linear force and motion. They consist of a cylindrical barrel, a piston, and a piston rod that moves back and forth within the barrel. To manufacture hydraulic cylinders, steel billets are first heated and then shaped using specialized machinery such as a hydraulic press or a hot rolling mill. This process, known as forging, involves applying immense pressure and heat to the steel billet to reshape it into the desired form. The forged steel billet is then machined and precision-cut to create the necessary features, such as the bore and the mounting holes, that are required for the hydraulic cylinder. This machining process ensures that the cylinder has the correct dimensions and tolerances to function properly. After machining, the steel billet is further heat-treated to enhance its mechanical properties. This heat treatment process involves heating the billet to a specific temperature and then rapidly cooling it, which improves its strength, hardness, and resistance to wear and fatigue. Once the steel billet has undergone forging, machining, and heat treatment, it is ready to be assembled into a hydraulic cylinder. The various components, such as the piston, piston rod, seals, and bearings, are carefully fitted together to create a fully functioning hydraulic cylinder. In conclusion, steel billets play a crucial role in the manufacturing of hydraulic cylinders. They are transformed through forging, machining, and heat treatment processes to create the necessary components with the desired properties. The resulting hydraulic cylinders are then used in a wide range of applications, providing efficient and reliable linear force and motion.

- Q:How do steel billets contribute to the manufacturing of telecommunications devices?

- Steel billets play a significant role in the manufacturing of telecommunications devices in several ways. Firstly, steel billets serve as a raw material for the production of various components used in telecommunications devices. These components include structural frames, housing, brackets, and mounts, among others. The strength and durability of steel make it an ideal choice for these parts, as they need to withstand harsh environments and provide stability to the devices. Furthermore, steel billets are often used in the production of transmission towers and antenna masts, which are essential for the efficient transmission and reception of signals in the telecommunications industry. These towers and masts need to be sturdy and capable of supporting heavy equipment to ensure uninterrupted communication. Steel, with its high strength and load-bearing capacity, is an ideal material for such applications. Moreover, steel billets are also used in the manufacturing of cable trays and conduits that are essential for organizing and protecting the various cables used in telecommunications devices. These cable management systems ensure that the cables are properly routed and protected from external factors such as moisture, heat, and physical damage. Steel's resistance to corrosion and its ability to withstand extreme conditions make it an excellent choice for these purposes. In addition to its physical properties, steel billets contribute to the manufacturing of telecommunications devices due to their cost-effectiveness. Steel is widely available and relatively inexpensive compared to other materials, making it a preferred choice for manufacturers. Its versatility and ease of fabrication also contribute to the efficient production of telecommunications devices. Overall, steel billets play a crucial role in the manufacturing of telecommunications devices by providing raw materials for various components, supporting infrastructure, and ensuring efficient cable management. Their strength, durability, cost-effectiveness, and availability make them an indispensable material in the telecommunications industry.

- Q:How are steel billets used in the manufacturing of electrical components?

- The advantageous properties and suitability of steel billets make them commonly used in the manufacturing of electrical components. This process begins by producing steel billets, which are solid rectangular or square bars of steel formed through casting or hot rolling. When manufacturing electrical components, steel billets act as the raw material that undergoes various processes to become specific components. An example of this is the production of transformer cores, which are essential components in electrical transformers. Transformer cores made from steel billets offer high magnetic permeability, low hysteresis loss, and low electrical conductivity, making them perfect for magnetic induction applications. To manufacture transformer cores, the steel billets are heated and then shaped into thin laminations by passing them through a series of rolling mills. These laminations are stacked together and insulated with materials like varnish or paper, creating a core that efficiently transfers electrical energy between coils. Steel billets are also utilized in the production of electrical connectors, terminals, and busbars. These components require high strength, excellent electrical conductivity, and resistance to corrosion. Steel billets can be further processed using methods like forging, machining, or extrusion to create these components. Apart from transformers and electrical connectors, steel billets can be employed in manufacturing other electrical components such as motor cores, switchgear panels, and circuit breaker parts. The versatility of steel billets allows for the production of components with various shapes and sizes, catering to the specific requirements of the electrical industry. In conclusion, steel billets play a crucial role in the manufacturing of electrical components by providing a strong, durable, and cost-effective raw material that can be shaped and processed to meet the diverse needs of the electrical industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Converter Continuous Casting Square Steel Billet Q235 Q275 Q345 for Construction

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords