Concrete HC Slabs for Floor Making Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Concrete HC Slabs for Floor Making Machine

1. Structure of Concrete HC Slabs for Floor Making Machine:

The machine uses hydraulic lifting system, easy to revolve. It can reduce labor intensity and improve production efficiency. Machine body adopts anti-rust technology. Key parts, like hopper are welded by stainless steel. Wearing parts like reamers, side form, vibration board, stock guide and other parts are all welded with alloy. Both sides of the wall panels can put reinforcement wires, diameter can reach 6mm. Work area is orbital or no orbital.

According to the specialty of the local materials, we provide matching method to insure customer produce standard panels (general materials: fly ash, slag, ceramsite, cinders, cinerite, pumice, vermiculite and so on). Reduce the overall cost of building, increase indoor usable space.

High production efficiency, annual output square meters above 150000m.

2. Main Features of Concrete HC Slabs for Floor Making Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

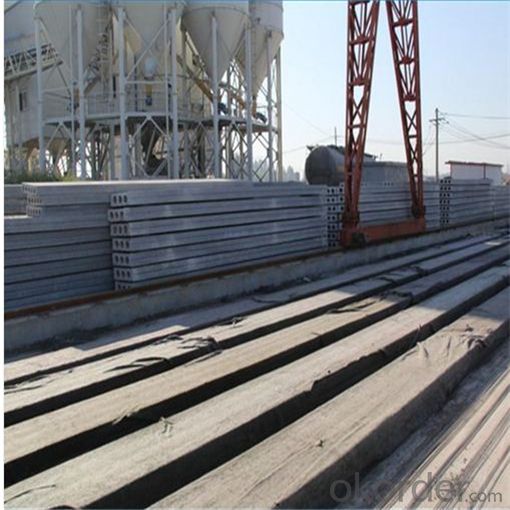

3. Concrete HC Slabs for Floor Making Machine Images:

4. Concrete HC Slabs for Floor Making Machine Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

Production Process

Rebar tensioning

Raw materials preparing

Molding

Our customers

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

- Q:Mechanical material forming cold forming and thermoforming What is the difference, the main processing of what materials

- Cold forming is not in the case of heating the material for punching, bending, stretching and other processing methods. Cold forming process cold forging, cold rolling, forging and so on. The main advantages of cold-formed steel structure: 1, compared with the thicker hot-rolled steel, cold-formed steel can be processed into smaller load and shorter span.

- Q:I have a go cart with a 6.5 horsepower general machinery small engine. The engine starts right up first pull but as soon as I press the throttle, the engine dies. The only way to use it is if you start the engine with the throttle being pushed, but if you let it idle for about 10 seconds after that it dies. Whats going on here??? Any help would be greatly appreciated.

- clean carb...idles ok but given gas stalls....when u hit throttle u open letting in more air...not enough gas..

- Q:Is machinery still being built?

- yes it is

- Q:Such as in terms of construction equipment like a crane, what is the maximum amount of weight that can be lifted by any existing machine?

- A crane's limitation is defined as metre-tonnes, because it is the moment that creates the limitation of the crane lift. A crane does the same amount of work to lift 50 tonnes at 10 metres as it does to lift 100 tonnes at 5 metres. That being said; I believe the largest single lift was perfromed by one of forty-two Lampson Tranis Lift IIs in Corpus Christi TX. The actual load was 1000 tonnes. And this just happens to be a MOBILE unit, on top of everything else!

- Q:why on ship machinery's are installed forward-aft & not port starboard?

- I guess it helps if the axis of the propulsion machine is in line with the propeller shaft so it doesn't need some sort of right angle drive.

- Q:Any manufacturers or suppliers give the details of above matter in India

- Here's okorder /

- Q:Where do i sell rubber rollers for printing and industrial machineries?

- I can only think of OKorder, LOL!!!!

- Q:Looking at their lists of duties, it seems MR's are machinists, and MM's repair machines/pipes, etc.

- MR What they do The duties performed by MRs include: ? repairing and operating auxiliary machinery; ? calculating time and material needed for machine shop work and the repairing of auxiliary machinery; ? drawing sketches and preparing specifications for replacement parts; ? working from sketches and specifications to produce replacement parts; ? operating machine shop equipment, such as lathes, drill presses, shapers, bench grinders, milling machines, boring mills, power hacksaws and computer numerically controlled machinery; ? working with precision measuring instruments such as micrometers, depth gauges, verniers, calipers, gauge blocks, protractors and dial indicators; ? engraving metal and other materials; ? performing electroplating and flame spraying operations. --------------------------------------... MM What They Do The duties performed by MMs include: ? aligning piping systems for oil, water, air and steam, and controlling the operation of ship boilers and steam turbines used for ship propulsion and service systems; ? controlling operation of turbo generators used to produce electrical power; ? cleaning, adjusting, testing and performing other preventive maintenance on a ship's boilers, main engines, turbo generators and other auxiliary machinery including steering engines, elevators, winches, pumps and associated valves; ? operating and maintaining desalinization plants (distilling plants) to make fresh water from sea water; ? maintaining refrigeration plants, air conditioning systems and galley equipment; ? repairing or replacing valves, pumps, heat exchangers, compressors, steam turbines and hydraulic or pneumatic control devices; ? making entries in and analyzing machinery operating records and reports. --------------------------------------... You should be able to see the difference in primary duties.

- Q:would these include non motorized equipment used for processing?

- Baler------ This is pulled by the tractor and used to make bales out of crops like hay. It makes a round bale that is 4'x4' tall. Each bale will feed about 25 cows a day. Combine------ This is used to harvest all kinds of crops. It does more than one thing--like pick and clean the crop. It has a sieve in it to get rid of the crop junk. They even have special ones if the farmer has lots of hills. Chisel Plow----- Plows dig up the soil to get it ready for planting. It will turn over the dirt as it digs. Cotton Picker----This machine picks cotton and puts it into the back. The cab has air conditioning and a cassette player/ radio/ and weather radio. It has a special seat for back support. Mower---- This is pulled by a tractor and mows down grass and low growing things. Row Planter---The containers at the top hold the seeds to be planted. This is pulled across the field that the farmer wants to plant. Row Planter---The containers at the top hold the seeds to be planted. This is pulled across the field that the farmer wants to plant. Seed Drill--- This is pulled by a tractor. It is used to plant grains and vegetable seeds. This can make different kinds of ditches that the seeds go in depending on what kind of soil there is. Sprayer--- This is used if the farmer needs to spray their crops for anything [like bugs]. It has a great cab, or place where the driver sits. The equipment company builds these to make farmers more comfortable while they work. Tractor--- This is one of the most important pieces of equipment that a farmer has. He uses it to pull equipment and crop wagons. The equipment company makes the cabs of these very comfortable, too. The farmer picks the tractor size based on what he wants to pull with it. ()

- Q:How to choose the material when doing mechanical design

- Analysis of the advantages and disadvantages of this material, and then in the mechanical design manual can be found in the application of materials such as high-quality steel:

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Concrete HC Slabs for Floor Making Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords