Composite Geotextiles for Architectural Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Composite Geotextiles for Architectural Engineering

Description Of Composite Geotextiles for Architectural Engineering

Composite material is a general term for the synthetic materials used in civil engineering. As a kind of civil engineering materials, it is to synthetic polymers, such as plastics, chemical fiber, synthetic rubber as raw material, made of various types of products, placed inside the soil, surface, or various kinds of soil play to strengthen or to protect the soil. The application of the technology of soil engineering synthetic materials will be divided into the type of the material of the soil, the soil, the soil, the special material and the composite. The special materials for the special materials include the soil engineering film bag, the soil engineering net, the geotechnical mesh pad, the soil working chamber, the soil texture, the bentonite mat, the polystyrene foamed plastics (EPS), etc.. The composite material is made from the above mentioned materials, such as composite coating, composite material, composite material, composite waterproof and drainage (drainage), etc..

Main Features of Composite Geotextiles for Architectural Engineering

The advantages of the composite is that the weight is light, and the overall continuity is good (can be made into a large area of the whole), construction is convenient, high tensile strength, corrosion resistance and resistance to microorganisms. The disadvantage is that, without special treatment, anti ultraviolet ability, such as exposure to ultraviolet radiation, is easy to aging, but if not directly exposed, the anti aging and durability performance is still high.

Applications of Composite Geotextiles for Architectural Engineering

1, for the stability of highway, railway roadbed.

2, used to bear the weight of the embankment and shallow water treatment.

3, used to prevent the landslide and the load of the gravity of the hybrid retaining wall.

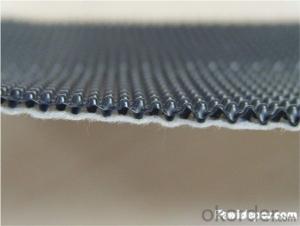

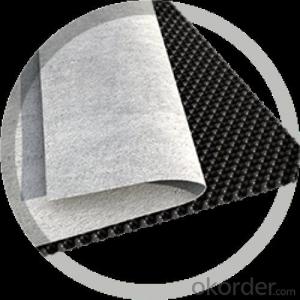

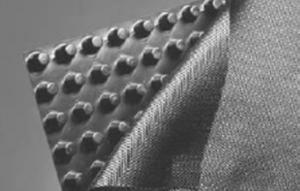

IMages of Composite Geotextiles for Architectural Engineering

FAQ:

1. What are we supplying?

We are specialized in producing .geotextile , geocell, geogrid, geomembrane

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q:What is the purpose of using geocells in flood protection applications?

- The purpose of using geocells in flood protection applications is to provide a strong and stable barrier that can prevent soil erosion, manage water flow, and reinforce embankments or levees during flooding events. Geocells are designed to confine and stabilize soil, preventing it from being washed away or displaced by the force of floodwaters. This helps to maintain the integrity of flood protection structures and reduce the risk of flooding in vulnerable areas.

- Q:What are the advantages of using geotextile mats in erosion control for riverbanks?

- Geotextile mats offer several advantages for erosion control on riverbanks. Firstly, they provide immediate protection by preventing soil erosion and retaining sediment, effectively stabilizing the riverbank and reducing the risk of bank collapse. Secondly, these mats allow water to pass through while filtering out sediments, enabling natural water drainage and preventing the buildup of excess water pressure that could further erode the riverbank. Additionally, geotextile mats are durable and resistant to degradation, ensuring long-term erosion control. They are also easy to install and maintain, making them a cost-effective solution for riverbank stabilization. Overall, the use of geotextile mats in erosion control for riverbanks offers effective and sustainable protection against erosion, maintaining the ecological balance and preserving the stability of river ecosystems.

- Q:Can geosynthetics be used for reinforcement in railway track construction?

- Yes, geosynthetics can be used for reinforcement in railway track construction. Geosynthetics such as geogrids, geotextiles, and geomembranes are commonly used to improve the stability and performance of railway tracks. They help in reducing settlement, improving track drainage, increasing load-bearing capacity, and preventing the migration of fine particles. Overall, the use of geosynthetics in railway track construction enhances the durability and longevity of the tracks.

- Q:How do geosynthetic materials contribute to sustainable construction practices?

- Geosynthetic materials, such as geotextiles, geogrids, and geomembranes, play a crucial role in promoting sustainable construction practices. These materials are designed to enhance the performance and durability of various civil engineering projects while minimizing environmental impact. They contribute to sustainability by reducing the need for natural resources, improving soil stabilization, preventing soil erosion, and enhancing the overall efficiency of construction processes. Additionally, geosynthetics offer long-term cost savings, as they extend the lifespan of structures and minimize maintenance requirements. Overall, the use of geosynthetic materials contributes to sustainable construction practices by balancing economic, social, and environmental considerations.

- Q:What are the specific applications of geosynthetic clay liners in earthwork projects?

- Geosynthetic clay liners (GCLs) have various applications in earthwork projects. These include their use as a barrier in landfill construction to prevent the migration of contaminants, as a liner in ponds and reservoirs to prevent seepage, and as a component in slope stabilization to enhance stability and prevent erosion. GCLs also find applications in road construction, canal lining, and mining activities to provide effective containment and protection against water infiltration or contamination. Overall, the specific applications of GCLs in earthwork projects are primarily focused on containment, seepage control, and erosion prevention.

- Q:How are geotextile tubes used in dewatering applications?

- Geotextile tubes are commonly used in dewatering applications to remove water from areas such as construction sites, mine tailings, or contaminated areas. The tubes are filled with sediment-laden water, allowing the water to pass through the geotextile fabric while retaining the sediments inside the tubes. This process effectively separates the solids from the water, allowing for efficient dewatering and sediment containment.

- Q:What is the purpose of using geotextiles in earthwork projects?

- The purpose of using geotextiles in earthwork projects is to improve soil stability, drainage, and erosion control. Geotextiles act as a barrier between different soil layers, preventing mixing and promoting better compaction. They also allow for water to pass through while retaining soil particles, thereby enhancing drainage and preventing waterlogging. Additionally, geotextiles help to control erosion by reducing the impact of water flow and protecting the underlying soil from being washed away.

- Q:Are there any specific earthwork products available for railway projects?

- Yes, there are specific earthwork products available for railway projects. These include materials such as ballast, sub-ballast, and subgrade that are used to provide stability and support for the railway tracks. Additionally, geosynthetic products like geotextiles and geogrids are commonly used to enhance the performance and longevity of railway earthworks.

- Q:How do geosynthetic products contribute to soil erosion prevention in orchards?

- Geosynthetic products play a crucial role in preventing soil erosion in orchards. These specially designed materials, such as geotextiles, geogrids, and geocells, offer effective erosion control measures by stabilizing the soil, improving its water permeability, and providing reinforcement against potential erosion forces. They help retain soil particles in place, reduce runoff, and enhance water infiltration, thus ensuring the stability and preservation of orchard soils and preventing erosion damage.

- Q:What are the benefits of using geotextile mats in roadway reinforcement systems?

- Geotextile mats offer numerous benefits in roadway reinforcement systems. Firstly, they improve the stability and load-bearing capacity of the road by distributing the applied loads more evenly. This helps prevent rutting, potholes, and structural failures. Secondly, geotextile mats act as a barrier, preventing the mixing of base materials and subgrade soils, which reduces the risk of contamination and erosion. Additionally, these mats enhance drainage by allowing the passage of water while preventing the loss of fine particles. This helps to maintain the road's structural integrity and prevent water-related damages. Lastly, geotextile mats are cost-effective as they require minimal maintenance and prolong the lifespan of the roadway, reducing the need for frequent repairs and replacements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Composite Geotextiles for Architectural Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords