Cold rolled steel sheet in coil wholesale alibaba

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 59450 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

These cold rolled steel coil/sheet grades have excellent formability, which facilitates cold forming operations, and are ideal for deep drawing. Our range of steels for cold forming offer excellent forming performance, due to the low scattering of their chemical composition and their mechanical properties, which guarantees processing consistency.

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc,

construction & building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving,

containers, drums

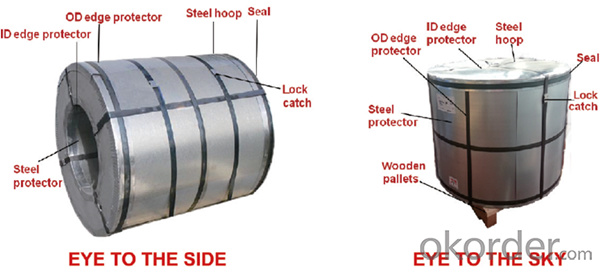

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order..

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q:How do steel coils contribute to the construction equipment industry?

- Steel coils are essential in the construction equipment industry as they are used to manufacture various components like beams, plates, and tubes. These coils provide the necessary strength and durability needed for constructing heavy machinery and equipment. Additionally, steel coils are also utilized in the fabrication of structural frameworks, reinforcing bars, and other critical parts, ensuring the integrity and safety of construction equipment.

- Q:How are steel coils protected from chemical damage?

- Steel coils are typically protected from chemical damage through various methods such as applying protective coatings or using barrier films. These protective measures act as a barrier between the steel surface and any potentially corrosive chemicals, preventing direct contact and minimizing the risk of chemical damage.

- Q:What are the different methods of coil slitting for precision cuts?

- There are several methods of coil slitting for precision cuts, including rotary slitting, loop slitting, and double knife slitting. Rotary slitting involves using a circular blade to cut through the coil, while loop slitting utilizes a looping mechanism to create tension and then cuts the coil with a straight blade. Double knife slitting, on the other hand, employs two blades that move in opposite directions to cut the coil. These methods enable precise and efficient cutting of coils into narrower strips for various industrial applications.

- Q:What are the different coil cutting machine options available for steel coils?

- There are several coil cutting machine options available for steel coils, each catering to different requirements and specifications. Some of the common options include: 1. Slitting Machine: This machine is used to slit the large steel coils into narrower strips or slits. It typically consists of a circular blade that moves across the width of the coil, cutting it into the desired widths. Slitting machines can handle a wide range of steel coil thicknesses and are commonly used in industries such as automotive, construction, and manufacturing. 2. Cut-to-Length Machine: This type of machine is used to cut steel coils into specific lengths. It is equipped with a shearing mechanism that cuts the coil based on the programmed length. Cut-to-length machines are particularly useful for applications where precise and consistent lengths are required, such as in the production of steel sheets or plates. 3. Rotary Shear Machine: A rotary shear machine is designed to cut steel coils into smaller pieces or squares. It utilizes a rotating drum with multiple cutting blades that shear the coil in a continuous process. This type of machine is often used in industries that require smaller steel pieces for further processing or assembly. 4. Guillotine Shear Machine: This machine is equipped with a large blade that moves vertically to cut steel coils. It is commonly used in applications where high precision and high-speed cutting are required. Guillotine shear machines can handle thicker steel coils and are often employed in heavy-duty industries such as shipbuilding and metal fabrication. 5. Laser Cutting Machine: Laser cutting machines offer a highly precise and versatile method for cutting steel coils. They use a focused laser beam to melt or vaporize the material, resulting in a clean and accurate cut. Laser cutting machines are suitable for a wide range of steel coil thicknesses and can handle complex shapes and patterns. These are just a few examples of the coil cutting machine options available for steel coils. The choice of machine depends on factors such as coil thickness, desired cutting precision, required output volume, and specific application requirements.

- Q:How are steel coils tested for strength and durability?

- Steel coils are tested for strength and durability through a series of rigorous tests. These tests typically include tension tests, bend tests, and hardness tests. Additionally, the coils may undergo impact tests to evaluate their resistance to sudden forces. These tests help ensure that the steel coils meet the required standards and can withstand various conditions and applications.

- Q:Cooling bed generally a part of the steel rolling mills

- Another type of cooling bed is used for square stock. It consists of several beams with angles cut upward from the bottom. The beams move in alternating fashion so that the square beam is lifted and sat into the next 'tooth'. The angle is cut so that the beam rotates as it is set down. This keeps the stock straight while it cools.

- Q:What are the different types of coil edge trimming machines?

- There are several different types of coil edge trimming machines available in the market. These machines are specifically designed to trim the edges of coils or rolls of various materials such as metal, paper, plastic, or fabric. Each type of machine has its own unique features and capabilities, catering to different trimming requirements. 1. Manual Edge Trimmers: These machines are operated manually, where an operator manually feeds the coil and trims the edges using a cutting tool or blade. Manual edge trimmers are typically used for low volume trimming applications and require the operator's skill and precision. 2. Semi-automatic Edge Trimmers: These machines have automated feeding mechanisms that assist in feeding the coil through the machine. The trimming process is still performed manually by the operator using a cutting tool, but the feeding mechanism reduces manual effort and increases productivity. 3. Automatic Edge Trimmers: These machines are fully automated and require minimal operator intervention. They are equipped with advanced sensors and controls that enable precise and consistent trimming of coil edges. Automatic edge trimmers can handle high volumes of coils and are often integrated into production lines for continuous trimming operations. 4. Rotary Blade Edge Trimmers: These machines utilize rotary blades to trim the edges of coils. The rotary blades rotate at high speeds, cutting through the material with precision. Rotary blade edge trimmers are commonly used for plastic or fabric coils, as they provide clean and smooth cuts. 5. Guillotine Edge Trimmers: These machines use a guillotine-like cutting mechanism to trim the edges of coils. The cutting blade moves vertically and cuts through the coil material in a straight line. Guillotine edge trimmers are suitable for trimming metal or paper coils, as they provide straight and accurate cuts. 6. Laser Edge Trimmers: These machines use laser technology to trim coil edges. The laser beam precisely cuts through the material, resulting in clean and precise edges. Laser edge trimmers are often used for delicate or high-value materials, as they minimize the risk of damage or distortion. Each type of coil edge trimming machine has its own advantages and limitations, and the choice of machine depends on the specific requirements of the application. Factors such as material type, coil dimensions, trimming precision, and production volume should be considered when selecting the appropriate machine.

- Q:How are steel coils inspected for oil or rust residues?

- Steel coils are typically inspected for oil or rust residues through visual examination, as well as using various testing methods such as wiping the surface with a white cloth to check for any visible stains or residues. Additionally, some inspectors may also use specialized equipment such as ultraviolet lights or moisture detectors to identify any hidden oil or rust contaminants.

- Q:what is the difference between METAL and STEEL?

- Steel is a type of metal. There are many types of metals - some are simple elements such as copper, tin, iron or lead whilst others are mixtures of elements known as alloys such as bronze, brass... and steel. EDIT - and yes, once again Wikipedia has led someone astray. Metals are NOT exclusively elements. Metals are defined by their properties of being ductile, malleable and sonerous. Thus metals include both elements and alloys. Or is someone seriously proposing that a person building a steel structure such as a ship is not working in metal?

- Q:I read that contrary to popular belief, today's folded steel swords are only made that way for tradition and cosmetics. In the past steel was very impure and therefore had to be folded in order to make a good sword. Today's steel manufacturing provides very pure steel and so folding the metal only makes it look nicer, but does nothing to improve the function of the blade.What do you think of this?

- That's true of Cheness modern metallurgical materials and forge construction. Modern monostone is several times stronger than the steel used in Medieval Europe or Feudal Japan. In Japan it was said that good steel doesn't break when you hit something hard, but folds/bends. That meant good steel as rated back then would take a permanent bend at no more than 15 or 30 degrees of bending. Modern monosteels can be bent 45 degrees without a permanent bend.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cold rolled steel sheet in coil wholesale alibaba

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 59450 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords