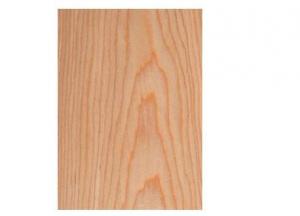

Cherry Engineered Wood Veneer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 SQM m²

- Supply Capability:

- 200000 SQM/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of the Cherry Engineered Wood Veneer

| Length | 2150-3100mm |

| Width | 320-900mm |

| Thickness | 0.15-2.0mm |

| Normal size | 2500*640*05mm |

Instruction of the Cherry Engineered Wood Veneer

Engineered Veneer is a sliced reconstructed real wood veneer. It is made from natural timber

which color is enhanced, reformed to a square "log" and then re-sliced in rectangular veneer

sheets.

The usage of the Cherry Engineered Wood Veneer

It is widly applid in the following regions: door inserts, wall panels, ceiling panels, privacy

screens, architectural millwork, and furniture inlays, hotel, shopping mall, restaurtant, loung,

commercial space, chains, office, halll dinning, expo, column, furniture,slide door, interior door,

house, bar etc.

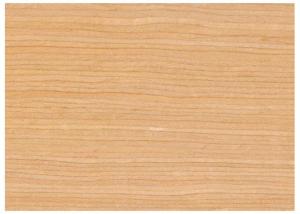

The main wood grain of Cherry Engineeres Wood Veneer includes

Teak, Oak, Elm, Wenge, Walnut, Cherry, Maple, Ash, Ebony, Zebrawood, Rosewood, Apricot,

Sapelli, Vine Burt etc.

The package of the Cherry Engineers Wood Veneer

Package details: Wood pallet packing and wrapped with waterproof plastic, then fixed by iron belt.

Delivery details: China main port and 7-30 days after we receive your deposit.

Engineered Wood Veneer are good used for furniture decoration

- Q:Veneer production process is this?

- The most effective way to improve the plasticity of wood is to adjust both the temperature and the moisture content at the same time to increase the temperature of the wood while increasing the moisture content of the wood

- Q:The Sliced ??veneer manufacturing process

- and then the cutting of the wood must be selected according to the diameter of the logs, the wood texture and the wooden side on the chopper

- Q:How to seize the key to solve the problem of slow development of paste veneer process?

- However, due to the development of paste veneer technology is relatively lagging behind, part of the veneer products, the appearance and durability of the product failed to be effectively guaranteed

- Q:Often, the processing of natural vines is done by slicing the method.

- Different diameter logs should use different sawing programs. The thick lines in the figure are the saw lines, and the direction of the arrows is the planing direction of the planer

- Q:What is the size of the veneer?

- , imports of veneer up to 3 meters long. Width is generally more than 9 cm wide natural.

- Q:The Veneer dyeing quality requirements

- after the factory processing bleach (usually takes about 6 hours, how many times to see the wood) is the purpose of color uniform

- Q:Wooden door with veneer ruled, pattern is produced by different cutting methods

- Plain Slicing (Flat Slicing, Flat cut) - also known as flat cut, flat slices / plain film, string cut veneer is the section of the knife along the center of the parallel line

- Q:A lot of Advantages of veneer

- With logs like natural, beautiful texture. Easy processing, rapid construction, saving manpower.

- Q:Brief description of veneer production process

- First, the wooden side into the cooking pool, the tree species, wooden specifications should be carried out separately; water temperature is best to maintain room temperature, and slowly warming,

- Q:Different veneer has different production processes

- Most furniture companies believe that science and technology veneer is not a native wood, but what is it, they also do not know, or simply called "artificial veneer".

1. Manufacturer Overview |

|

|---|---|

| Location | Linyi,China |

| Year Established | 2009 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Asia;Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Lianyungang;Qingdao |

| Export Percentage | 70% - 80% |

| No.of Employees in Trade Department | 800 people |

| Language Spoken: | Chinese |

| b)Factory Information | |

| Factory Size: | Above 120,000 square meters |

| No. of Production Lines | Above 15 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Cherry Engineered Wood Veneer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 SQM m²

- Supply Capability:

- 200000 SQM/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords