High Quality Low Carbon wood 004

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 sq.m, m²

- Supply Capability:

- 400000 sq.m. Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General information of low carbon wood

|

Raw material |

Sawdust, corn-straw and tailing, can be recycled after using. |

|

Technology |

Utilizing molecular structure of crystalline-state solidification, shaping under normal temperature and pressure with low carbon emission. |

|

Installation |

Stitching, wet-sticking and dry-fasten connecting |

|

Character |

Favorable corrosion resistance, non-ignitable, water-proof, UV-resistant, high resistance to fire, water and insects. |

|

Lead time |

30 days after receiving buyer's original L/C or Prepayment |

|

Package |

Seaworthy Export Standard Wooden Pallet |

|

Four breakthroughs |

Comprehensive utilization of natural resources: Be recyclable, using sawdust, corn-straw and tailing as materials. The product can be recycled after using. |

|

Low carbon and energy saving in the course of production: Adopting the independent individual property’s technology, utilizing molecular structure of crystalline-state solidification, shaping under normal temperature and pressure with low carbon emission. | |

|

Environmental and healthy in the course of construction and using: Synthesized by natural inorganic raw materials, nontoxic, odorless and non-radiative simple installation, which could save energy cost and reduce and waste emission, raise efficiency and reduce erection time. | |

|

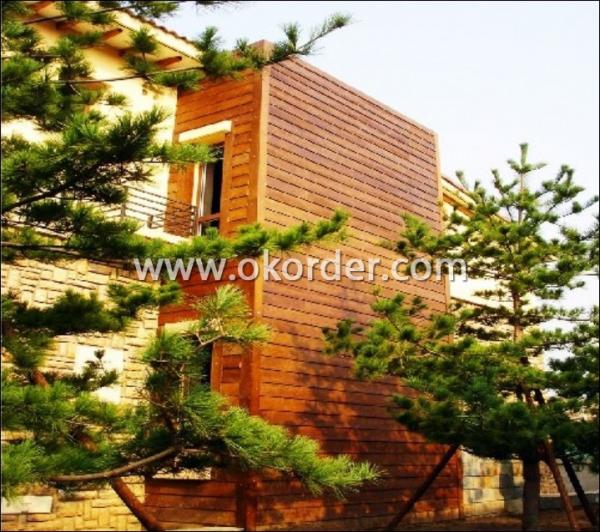

From nature, beyond nature: Full realization of the natural texture, high resistance to fire, water and insects. Do not rot or fade after long time usage. Super self-cleaning needs low maintenance cost. Vivid color and appearance provides a wide space to designers. | |

|

Six advantages |

Lower more than 50% cost, enhance building's performance to price ratio. |

|

Cutting at will, Fixing easy, Shorting project time. | |

|

Good performance in resistance to elements, corrosion-resistant ,resistance to termite, fire resistance and water-resistant, far from distortion and discolorations in 30 years. | |

|

Well self-cleaning, low cost in later maintenance: Don't need professional maintenance in 30s(Cleaning with water only), saving much cost. | |

|

Customize the color, showing individuation: Beyond 400 kinds of colors, designers could exhibit their imagination. | |

|

Compound with natural inorganic materials: Without formaldehyde and toluol, sustained releasing negative oxygen ion, forming nature oxygen bar. | |

|

Special specifications are available on customers' requirements. | |

Specification of low carbon wood

Standard: 3000mm(L)×1200mm(W)×15mm(T)

Standard length: 3000mm

Standard width: 120mm,150mm,200mm,300mm(including 3mm kerf width)

Standard thickness: 15mm

Technical information of low carbon wood

|

Density |

1.26g/m3 |

Folding strength |

10Mpa |

|

Dry-shrinkage rate |

0.05% |

Elastic modulus |

7211Mpa |

|

Wet expansion rate |

0.17% |

Shear strength |

3.5Mpa |

|

Screw holding capability |

121N/mm |

Coefficient of heat conductivity |

0.69(W(m·k)) |

|

Frost resistance |

Thaw-freeze cycle after 30 times, no slip crack and peeling off | ||

|

Unpermeability |

No drop appearing on the bottom after 24 hours. | ||

|

Impact strength |

3.3KJ/m2 | ||

Products exhibition of low carbon wood

Low carbon wood sheets with thin grain

Low carbon wood sheets with thick grain

Project picture of low carbon wood

- Q:Veneer has a very affordable, versatile features

- Veneer used in all kinds of high-grade wood decorative leather furniture on the surface, not only the price is reasonable and the function is also particularly good

- Q:Veneer production process is this?

- The use of these saws to produce veneer, the board rate is high, the quality of thin wood is better, chopper machine is more efficient.

- Q:What are the specifications for veneer?

- The price from a more than one square to several hundred and one square have, the general import of expensive than domestic

- Q:Slicing of thin slices of wood

- after cooking treatment; the cooking process should be reduced to more than 40 ℃, it should slow down the heating rate

- Q:The Production process of cooking

- The following table lists the cooking criteria for several types of wood, for reference only.

- Q:What is veneer, please explain in detail

- Veneer; veneer; hereinafter referred to as veneer) and its veneer decoration industry started in the last century 50's,

- Q:What is the veneer panel

- Veneer panel commonly known as panel. Is the solid wood board precision cut into a thickness of about 0.2mm meager veneer for the surface layer to the splint as the substrate,

- Q:Advantages and disadvantages of Technology veneer and natural veneer

- In personal terms. Science and technology veneer in the next few years will be to a certain extent, replace the natural veneer. hope this helps. Pure hand hope to give points. You can also ask

- Q:Part of the production process

- After the wood side has been cooked (ie, water heat treatment), the plasticity of the wood increases

- Q:Cut Slicing - The cut is a round of vertical cut logs, producing a veneer with a ruled ridge.

- To cut the oak-like wooden vines at a slight angle, to minimize the appearance of "scales" of wood grain, to produce a ruled veneer.

1. Manufacturer Overview |

|

|---|---|

| Location | Tianjin,China |

| Year Established | 2009 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 11% - 20% |

| No.of Employees in Trade Department | |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 500,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | High;Average |

Send your message to us

High Quality Low Carbon wood 004

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 sq.m, m²

- Supply Capability:

- 400000 sq.m. Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products