Ceramic Fiber Bulk with Low Thermal Capacity High Pure

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Fiber Bulk with Low Thermal Capacity High Pure

The sun ceramic fiber bulk are manufactured from high purity raw material alumina powder ,silica sand for the high temperature grades and zircon sand is also used. The ceramic mixture is heated in an high temperature electric furnace and the stream of molten material is drawn into fibers by either spinning or blowing .It is produced by advanced “blown” and “spun” processes .Ceramic fiber bulk shows a high temperature stability ,low weight and heat capacity and an outstanding sound absorption is complemented by their resistance to oxidation and reduction

Product Applications:

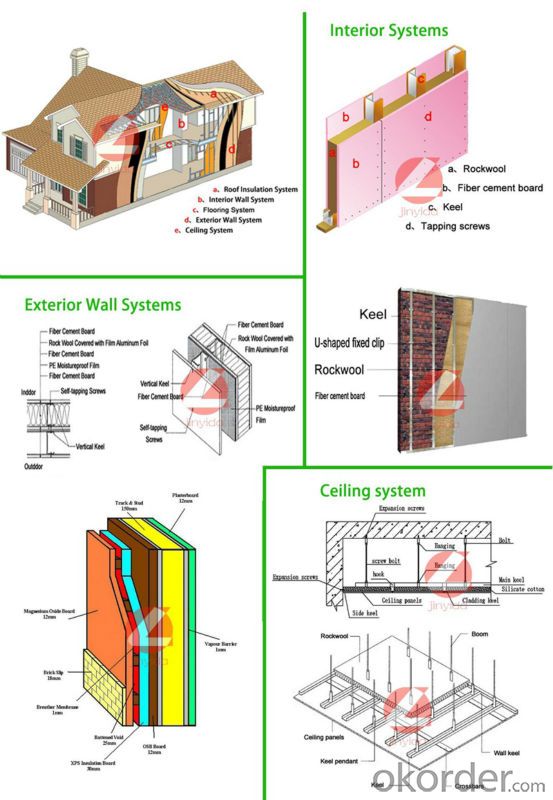

Ceramic Fiber Bulk are ideal for use in the below applications

The industry kiln, heating device, high temperature pipe lining

Power boiler,gas turbine and heat and nuclear power insulation

Chemical industrial high temperature equipment and heating

equipment lining

Fireproof and heat insulation for high building

Heat insulation for Kiln door and roof.

High-grade household appliances thermal insulation device

High temperature filtration etc

Product Advantages:

CNBM has success in its ceramic fiber products due to their cost-effectiveness and excellent insulating properties. CNBM also has experience in ceramic fiber blankets application and would like to assist you in product selection, system design, and installation techniques.

Main Product Features:

Great soft bulk with elastic.

Excellent thermal and chemical stability.

Low thermal conductivity.

Low thermal capacity.

Good acoustical and fire protection properties.

Low shrinkage

Convenient to cut or install

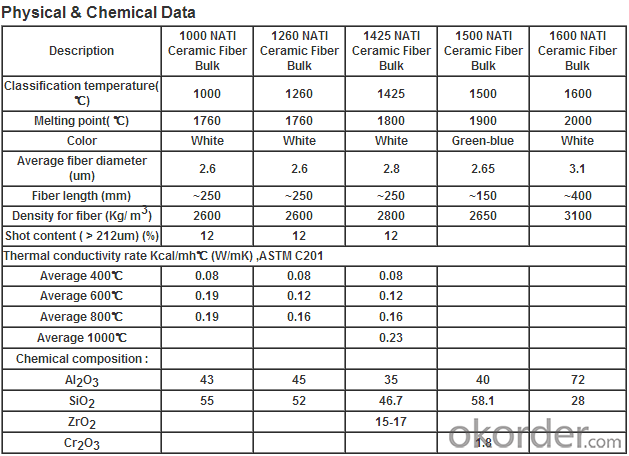

Product Specifications:

FAQ:

Q1. After an order is confirmed,when to deliver?

A1 :According to your order quantity, normally, 15-25 days after deposit received..

Q2.Can you provide sample?

A2: Yes, we can offer sample , and some samples are free

Q3:Can you delivery by express?

A3: Yes, we can delivery by any express

Q4.Can you accept OEM ?

A4: YES! We can according your demand to produce.

Product Picture

Produce Processing

Our Market

- Q:Aluminum silicate ceramic fiber cotton smoke will cause pneumoconiosis?

- 1, general masks, gauze, masks, etc., can not be used as dust masks.2, mask must pass GB 2626-2006 standard certification.3, it is recommended to choose N100 class dust masks.4, individual suggestions according to choose different shapes masks.5, it is recommended to change the filter gauze mask. Material recommended for silicone material.Through the above way, it can effectively prevent pneumoconiosis.

- Q:Glass fiber cotton, aluminum silicate cotton, rock wool, what's the difference between these three?

- Name: Cotton aluminosilicate ceramic fiber cotton, is an almost pure inorganic fiber, formed by blowing process production process or thrown silk spray, is a kind of low thermal conductivity, low heat capacity; high strength, high tear resistance, excellent machining performance. Aluminum silicate insulation material has become the best industrial furnace lining wall insulation materials, completely replace refractory bricks.

- Q:The difference between the ceramic fiber blanket and rock cotton blanket

- The heat capacity (heat storage capacity) of ceramic fiber lining is low: the heat capacity of ceramic fiber is only about l/10 of light heat resistant lining and light castable lining, and the heat capacity of lining material is proportional to the weight of lining. Low heat capacity means the furnace in the reciprocating operation absorb less heat and heating speed, greatly reducing the operational control of the temperature in energy consumption, especially for heating furnace and furnace, furnace shutdown has obvious energy saving effect.

- Q:What are the main differences between an ordinary furnace and a ceramic fiber furnace?

- Energy saving: ordinary furnace heat loss, heat rate, furnace insulation can. The holding time of ceramic fiber furnace is ten times higher than that of ordinary furnace, and it is easy to quench and quench.

- Q:What is the difference between the ceramic fiber cloth and the high silicon oxygen cloth?

- High temperature is similar to that of strength, service life, the price is high silica cloth. High silica fabric belongs to glass fiber.

- Q:What is the good heat insulation effect of glass fiber and aluminum silicate fiber, what are their respective advantages and disadvantages?

- Applicability: glass fiber (melting point 680 degrees) belongs to medium and low temperature insulation material, suitable temperature is below 700 degrees, aluminum silicate fiber belongs to high temperature insulation material, use fire temperature 1000~1790 degrees.

- Q:What is the density of ceramic fiber modules? The best insulation effect

- Ceramic fiber module density in 200-220, the first production of ceramic fiber module is generally made of ceramic fiber blown blanket, fiber blown blanket fine short, ceramic fiber module is made out of the expansion is relatively stable, but in recent years because of the cost of production, the majority of ceramic fiber module are thrown silk do relatively, the tensile force is big, according to your own combustion atmosphere of furnace temperature and heating module and intracranial, select the density and thickness of the ceramic fiber module. Just make the insulation layer, then recommend 200kg/ cubic meters. Ring fire-resistant insulation materials company has a specific index and design analysis.

- Q:Aluminum silicate needle carpet and ceramic fiber insulation performance of the good

- Aluminosilicate ceramic fiber has two different production processes, respectively, the rejection process and the blowing process. The carpet produced by the spinning process has long fiber length, high tensile strength and wide range of use. The blanket produced by blowing process is short in length and easy to break, and the scope of application is relatively narrow.

- Q:Should the ceramic fiber furnace be compacted?

- In view of the miniature furnace chamber, the ceramic fiber furnace can be selected, and once the furnace is formed, the length of the furnace is longer.

- Q:What is the diameter of the ceramic fiber? How to mix?

- Fiber diameter: rejection fiber more coarse, rejection fiber generally 3.0-5.0 - m, spinneret fiber is generally 2.0-3.0 - m;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Bulk with Low Thermal Capacity High Pure

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords