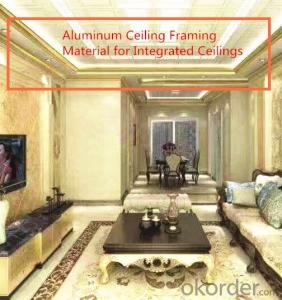

Ceiling Framing Material for Integrated Ceilings

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m

- Supply Capability:

- 1000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Introduction

As aesthetic values evolve, wood grain effect finishing is now becoming more and more popular in the fields of architectural decoration, furniture, electronics and home appliances. Wood grain effect finishing is a special powder coating process based on the latest technology in the surface finishing.

The wood grain finished aluminum profile is a perfect integration of the excellent aluminum properties with the natural appearance of natural resources such as wood, marble, etc. It is a wonderful combination of the state-of-the-art technology and aesthetics. The products have stable quality, appealing appearance and therefore a higher value of decoration.

2. Wood Grain Effect Features

(1). Materials:

can be transferred to all kinds of substrate shapes, including sheets.

(2). Effects:

The decorative effects of pictures, text and graphs, and all kinds of natural sceneries (such as wood, marble or granite grains) can be achieved through photographic technology.

(3). Aesthetic Value:

Patterns of the most precious woods, such as oak, chestnut, cherry and walnut, can be imitated.

(4). Durability:

Excellent weathering-resistance performance, durable in all kinds of applications.

(5). Cost Savings:

Maintenance free, will resume original effect simply by regular cleaning.

(6). Environmental Friendliness:

The special decoration needs can be realized without using wood; meanwhile the products can be recycled.

(7). Fields of Applications:

The wood effect can be applied to windows, furniture, components, appliances, transportation vehicles (airplanes, ships and cars) and other decorating materials. It can be furnished according to customer requirements

3. Chemical composition

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Impurity | Al |

6063 | 0.2-0.6 | 0.35 | 0.1 | 0.1 | 0.45-0.9 | 0.1 | 0.1 | 0.1 | 0.15 | Rest |

6061 | 0.4-0.8 | 0.70 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.15 | Rest |

6005 | 0.6-0.9 | 0.35 | 0.1 | 0.1 | 0.4-0.6 | 0.1 | 0.1 | 0.1 | 0.15 | Rest |

4. Mechanical property

Alloy | Temper | Tensile strength | Yield strength | Elongation |

6061 | T6 | ≥ 265Mpa | ≥ 245Mpa | ≥ 8% |

6063 | T5 | ≥ 160Mpa | ≥ 110Mpa | ≥ 8% |

T6 | ≥ 205Mpa | ≥ 180Mpa | ≥ 8% |

5. Anodized

Grade | Anodizing thickness | Hole scaling quality of oxide layer | |

Average thickness | Local thickness | P. Cr acid-erosion weight less method | |

AA10 | ≥10um | ≥8um | ≤30 mg/d m2 |

AA15 | ≥15um | ≥12um | |

6. Powder coating & wooden-grained

Coating thickness | Coating impress rigidity | Adhesive force of coating layer |

40-120um | Indentation hardness>80 | 0 grade

|

7.

Material | 6063,6060,6061,6005 |

Temper | T4,T5,T6 |

Surface treatment | Mill Finish,Anodized,Eletropharesis,Powder Coated, Wooden Finish, Polish |

Colour | Silver,Black,Red,Blue,or as required |

Length | ≤6m |

Shape | Round,Square,T-slot,or as per the drawings and samples |

Fabrication | cutting,drilling,punching,bending,etc |

Wall thickness | ≥0.5mm |

Package | inner plastic paper interleaving each piece profile,outer fixed by plywood, or as per your requirements |

- Q:How to handle between two different levels of aluminum slabs

- First ceiling to the dragon skeleton, the above is the main keel, the main keel hanging under the board of the vice keel, the main keel plus vice keel total of at least 5CM height space

- Q:Can the aluminum slabs hang the balcony?

- Yes, but it is not necessary. The balconies are usually decorated with green wood or pine. With aluminum slab plate do not look good. And the lamp is the use of integrated ceiling lights, installed in the hanger affect the lighting.

- Q:My house north of the balcony to install curtains, but the above is the aluminum plate, three sides are glass, how to install curtains, or can play the curtains of other practices are also OK, but do not want to use the film.

- This depends on your home window is what the material, and if it is only the steel can only decorate the ceiling down to stay a curtain box. If it is steel can ask the next curtain, directly fixed on the window.

- Q:How about the quality of the ceiling

- Aluminum cords board ceiling quality is good, buy aluminum slab ceiling, look at the aluminum, film, back cover, from these three aspects to test the quality of aluminum gusset, AIA integrated ceiling quality in this area. First, check the aluminum material, because the average consumer is difficult to see the aluminum material, it is recommended that consumers look at the hardness of the buckle plate, and then check the paint is smooth, no burr, with or without color. Second, look at the film, the consumer can pull the edge of the board, if the phenomenon occurs from the film that is, this film is not close with the buckle plate; again look back cover (buckle back), which is a lot of consumers Ignore a part. Back cover generally have to be anti-corrosion treatment, hand to pull, if the back cover can pull out the description of its material is not good; and the general manufacturers will be in the back of the inkjet manufacturers logo and production date, through the presence of these words, Consumers can also identify the product is good or bad. If there are, that it is a regular factory of the machine production, is different from the small workshop, the quality is relatively guaranteed.

- Q:Aluminum buckle plate and steel which is better

- Plastic plate is improved by the second generation of ceiling material PVC, also known as UPVC, steel plate is the advantage of lower prices, thermal insulation performance, rich colors, production and installation is simple. However, according to the supervision of the steel plate market supervision and inspection results show that the current market, the quality of steel products, only 40% pass rate, bending strength, coating thickness, alkali resistance and other aspects of "water" serious. And the strength of the steel plate is low, easy to twist, not environmentally friendly (UPVC can not be recycled) weather resistance is poor, the combustion will release toxic gases .. metal ceilings and aluminum plate came from behind, the current market is also divided into aluminum Several grades: the first class of aluminum-magnesium alloy, also contains part of the manganese, the material has the greatest advantage of good antioxidant capacity, and because the addition of the amount of manganese, in strength and stiffness has improved, is the best ceiling material; The The second type of aluminum-manganese alloy, the strength and stiffness of the plate is slightly better than the aluminum-magnesium alloy, but the antioxidant capacity of a slight shortage of the third type of aluminum alloy, the plate contains manganese, magnesium less, so its strength and stiffness are obvious Lower than the aluminum-magnesium alloy and aluminum-manganese alloy, the antioxidant capacity of the general .. Aluminum buckle plate is the latest in recent years, a new type of decorative materials, it has a light, water, no dust, corrosion, easy to clean, easy to install, Strong sense, soft and beautiful colors and other characteristics, is completely environmentally friendly materials, welcomed by the user. The key to choosing an aluminum plate is not the thickness

- Q:Ready to give the room ceiling, with aluminum slab board, the type looked a little dizzy, the surface point of view, drawing board can clearly understand, that kind of film and anodized plate also how to read the plate can not read, Experts how to distinguish between these types of aluminum slab material, as well as anodized plate price of the money more appropriate, the price of roller coated more money appropriate, thank you

- Covered with a film on the surface of a film for a long time after the drum, you can knock on each other is the film board, the sound will be more boring, and roller plate and anodized plate, respectively, take two boards each knock, the sound will Have a strong sense of metal.

- Q:How to deal with the aluminum slab board ceiling installation Yuba after the resonance

- Now the high power Yuba itself noise on the big

- Q:If they say that the anti-oil strong nano-drawing does not change color in the end what is good? Please answer experts! Brushed the drawing of the nano is the nano of it

- Is the nano-wire plate is very cheap and practical general 100 quick money about one square meter

- Q:The company is to do the aluminum alloy ceiling, is the first to buy aluminum back to the factory, do the shape, and then take the outside to spray the surface of the oil. Aluminum is how much money to buy back a ton, on the outside called someone else processing fuel injection Is how much money a square as we count, we sold to the customer is the number of a square to count, I ask this, how do I calculate the cost of it? Our company's product cost is not what is the kind, is based on the requirements of customers to do.

- And then can be collected into the cost of manufacturing costs allocated to the comprehensive calculation of the cost.

- Q:PVC plastic gusset and aluminum gusset plate What are the differences?

- PVC plastic gusset: PVC as raw material, processed into the mouth of the profile, with a light weight, easy to install, waterproof, moisture, moth features, it is also a lot of changes in the surface color patterns, and pollution, There are sound insulation, good insulation performance, especially in the new process by adding a flame retardant material, so that it can be off from the fire, the use of more secure. It is low cost, good decorative effect, so in the home decoration ceiling material occupies an important position, as the bathroom, kitchen, balcony and other ceiling of the leading material. Ceiling is often used in interior design a way, people's sight is often more contact with it more time, so the shape of the ceiling and art processing is clearly affected the effect of space.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceiling Framing Material for Integrated Ceilings

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m

- Supply Capability:

- 1000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords