CC Aluminum Coil for Casting to Thinner Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CC Aluminum Coil for Casting to Thinner Coils

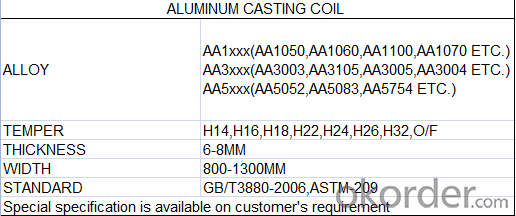

1.Structure of CC Aluminum Coil for Casting to Thinner Coils

CC Aluminum Coil for Casting to Thinner Coils is used in the factories that produce aluminum coil from 0.2mm to 6mm by thickness. Hot rolled y cold rolled son available. The thickness of CC Aluminum Coil for Casting to Thinner Coils is about 6-8mm. You can choose the alloys as your using and we will do our best to meet your requests.

2.Main Features of the CC Aluminum Coil for Casting to Thinner Coils

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Low tolerance

• Strict quality control

• Well packaged

3. CC Aluminum Coil for Casting to Thinner Coils

4. Production Process of CC Aluminum Coil for Casting to Thinner Coils

Cold Rolled

Hot rolled

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① What is the MOQ of CC Aluminum Coil for Casting to Thinner Coils

Usually the MOQ is 150 tons, but we also can make solution according to clients’ situation.

②How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

③Can you guarantee the quality of the products?

We are responsible for the quality of materials in a reasonable period of time to get a long-term cooperation with clients and we are glad to arrange and coordinate any third party inspection for you.

④What is the delivery time after purchase?

15 day with normal specification after receiving client’s deposit or correct LC

- Q:For the reaction at the anode:Al ----gt; Al3+ + 3eHowever, at the anode, oxygen are also produced and forms aluminium oxide(Al2O3) with aluminium.Are Oxygen produced by oxidation of water by electrolysis? or some reaction else?If Oxygen are produced by oxidation of water, then why it can be oxidise sinceAl ----gt; Al3+ + 3e E^0= + 1.66V2H2O ---gt; O2 + 4H+ + 4e E^0= - 1.23V(if refers to E null value) Oxygen should only be produced after all the Al have been finish oxidised.Both reaction happen at the same time? Is it possible?

- Anodising is a process in which the surface of a metal is modified. In the case of anodising aluminum the layer of aluminum oxide is made thicker. This is done by placing the aluminum in a sulfuric acid solution and passing a current through it so that it serves as an anode-the current releases oxygen at the surface of the aluminum increasing the aluminum oxide. I'm pretty sure this is from the reaction of the electric charge and the sulfuric acid producing oxygen as you showed in your last reaction with water. I hope this was helpful, I'm at work and don't have my old chem books and I dont' remember all this stuff off the top of my head.

- Q:My boyfriend sweats a lot and uses Mitchlum deodorant, a lot of it, under his armpits and waits til it dries to stop the sweating. I heard aluminium was bad for you, but he says natural deodorants don't work as well. What do you think?

- different styles and types of deodarants work on different people experiment on lots of deodarant and see which one where u can not use to much but is still petty effective

- Q:Are there any limitations to the widths of aluminum coils?

- Yes, there are limitations to the widths of aluminum coils. The width of aluminum coils is typically determined by various factors such as the manufacturing process, equipment capabilities, and industry standards. One limitation is the maximum width that the manufacturing equipment can handle. Coil processing machines have specific width capacities, which generally range from a few inches to several feet. If an aluminum coil exceeds the maximum width that the machine can accommodate, it may not be possible to process it. Another limitation is related to transportation and handling. Aluminum coils that are too wide may not fit within standard shipping containers or may be difficult to maneuver during transportation. Additionally, wide coils may require specialized handling equipment or additional support, which can increase costs and logistical challenges. Industry standards and application requirements also play a role in determining the limitations of aluminum coil widths. Different industries and applications have specific width requirements for their products. For example, the construction industry may have specific width specifications for roofing or cladding materials, while the automotive industry may have different requirements for body panels. Manufacturers need to consider these standards and customer needs when determining the maximum and minimum widths of aluminum coils. In summary, while aluminum coils can be produced in various widths, there are limitations due to manufacturing equipment capabilities, transportation constraints, and industry standards. These limitations must be considered to ensure the efficient production, handling, and utilization of aluminum coils in different applications.

- Q:wood aluminium windows?

- Vinyl looks MODERN and are in all the track homes. If you want you home to look cookie cutter choose the vinyl. If you have a nice home in an upscale neighborhood choose wood and any other other combo of wood and ?. If you are like the rest of us average shmos get the white vinyl

- Q:Can aluminum coils be used in curtain wall systems?

- Yes, aluminum coils can be used in curtain wall systems. Aluminum is a popular material choice for curtain walls due to its lightweight nature, durability, and corrosion resistance. Aluminum coils can be easily formed and shaped to create the desired profiles for curtain wall systems. Additionally, aluminum is available in a wide range of colors and finishes, allowing for customization and design flexibility. The use of aluminum coils in curtain wall systems also offers energy efficiency benefits, as aluminum has good thermal conductivity properties. Overall, aluminum coils are a suitable and commonly used material in the construction of curtain wall systems.

- Q:I'm ball milling aluminum into powder and I have filled the canister with some water to prevent the aluminum from igniting. The powder has begun to dissolve in the water. I'd like to know the best way to remove the dissolved aluminum from the water so I can get to the powder.There is around of cup of water in the canister, just to give an idea of the situation.

- Aluminum does not dissolve in water. In the presence of oxygen (and water), it becomes Aluminum Hydroxide which is worthless pyrotechnically. To boil the water off without heat, use a vacuum pump. You may be involving yourself in a very dangerous enterprise, especially since you don't seem to know anything about chemistry. If you are experimenting, I would keep the quantities very low, a gram or so.

- Q:Domestic production of color coated aluminum coil manufacturers which good?

- It is widely used in the field of architectural decoration, such as aluminum ceiling, aluminum plate and so on. There are many manufacturers of color coated aluminum rolls, big and small.

- Q:Are aluminum coils suitable for signage applications?

- Yes, aluminum coils are suitable for signage applications. Aluminum is a highly versatile material that offers several advantages for signage purposes. Firstly, aluminum coils are lightweight, making them easy to handle and install. This is particularly beneficial for large outdoor signs or banners that need to be mounted or hung. Additionally, aluminum is highly resistant to corrosion, ensuring that the signage will remain in good condition even in harsh weather conditions. This durability also makes aluminum coils suitable for long-term outdoor use, as they can withstand exposure to UV rays, moisture, and temperature changes without deteriorating. Furthermore, aluminum coils can be easily fabricated and shaped to create various sign designs, including flat panels, channel letters, and dimensional signage. They can be painted or coated with different finishes to achieve the desired aesthetic appearance, making them versatile for branding and marketing purposes. Another advantage of using aluminum coils for signage applications is their recyclability. Aluminum is a sustainable material that can be recycled repeatedly without losing its quality. This makes it an environmentally-friendly choice for businesses that prioritize sustainability and want to reduce their carbon footprint. In summary, aluminum coils are a suitable choice for signage applications due to their lightweight nature, corrosion resistance, durability, versatility in design, and recyclability.

- Q:Are there any limitations on the width-to-thickness ratio of aluminum coils?

- Aluminum coils have limitations on their width-to-thickness ratio. This ratio greatly influences the strength and performance of the coils. If the ratio is too high, problems like buckling, warping, or even coil failure can occur. The specific limitations on this ratio depend on factors such as the alloy composition, temper, and intended use of the coil. Different alloys and tempers have varying mechanical properties and can handle different ratios. Moreover, specific applications like roofing, automotive, or packaging may have their own requirements for the width-to-thickness ratio. Manufacturers usually provide guidelines and specifications for acceptable ratios based on their products. These guidelines ensure that coils are used within their intended capabilities and prevent issues caused by excessive ratios. Users and designers must consider these limitations and guidelines when selecting and using aluminum coils. Failing to adhere to these limitations can result in compromised performance, increased risk of damage, and potential safety concerns. Therefore, consulting the manufacturer's recommendations and industry standards is crucial for determining the appropriate width-to-thickness ratio for a given application.

- Q:What do you think of the stainless steel with copper and aluminum core cookware? And what's a good brand?

- You can also get stuff with a sandwich of copper / aluminum on the bottom. they aren't nearly as good as true All-Clad, but they are way cheaper and still make nice pots and pans.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CC Aluminum Coil for Casting to Thinner Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords