carbon seamless steel pipe/ASTM A53 Grade B Seamless Pipes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of carbon seamless steel pipe/ASTM A53 Grade B Seamless Pipes:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、Main Features of carbon seamless steel pipe/ASTM A53 Grade B Seamless Pipes:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

• Best after-service

3、carbon seamless steel pipe/ASTM A53 Grade B Seamless PipesSpecification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of carbon seamless steel pipe/ASTM A53 Grade B Seamless Pipes:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

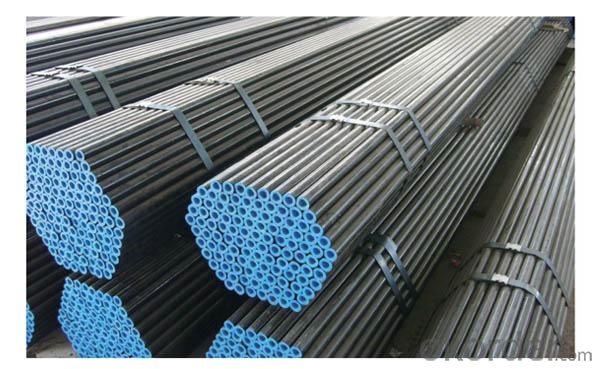

6、carbon seamless steel pipe/ASTM A53 Grade B Seamless Pipes Images:

- Q:Are steel pipes suitable for underground cable protection?

- Yes, steel pipes are suitable for underground cable protection. Steel pipes provide excellent durability and strength, making them ideal for protecting cables from external factors such as physical damage, moisture, and corrosion. They are able to withstand the weight of the soil and any potential pressure from above, ensuring the cables remain secure and protected. Additionally, steel pipes can be easily welded or connected to create a continuous and seamless conduit, further enhancing their effectiveness in underground cable protection.

- Q:Are steel pipes suitable for wastewater pumping stations?

- Yes, steel pipes are suitable for wastewater pumping stations. Steel pipes have excellent strength and durability, making them capable of withstanding the corrosive nature of wastewater and the high pressure involved in pumping. Additionally, steel pipes are resistant to extreme temperatures and can handle the heavy loads commonly associated with wastewater systems.

- Q:How are steel pipes used in the automotive industry?

- Steel pipes are commonly used in the automotive industry for various applications such as exhaust systems, fuel lines, and structural components. These pipes provide durability, resistance to corrosion, and high strength, making them ideal for transporting gases, fluids, and supporting the vehicle's structure.

- Q:SC15 what does galvanized steel pipe look like?

- Zinc plating: galvanized steel pipe hot galvanized and galvanized two kinds, hot galvanized, zinc coating thickness, with uniform coating, adhesion, long service life and so on. The cost of galvanizing is low, the surface is not very smooth, and the corrosion resistance of itself is much better than that of galvanized pipe. Refer to

- Q:Is there any difference between HFW steel pipe and ERW steel pipe?

- High frequency welding uses the skin effect to concentrate the energy of the high frequency current on the surface of the workpiece, and uses the proximity effect to control the position and range of the high frequency current flow path. The speed of the current is very fast, it can in a short period of time will be adjacent to the edge of the steel plate heating, melting, and through the extrusion docking, each has its own advantages, but also each has its own shortcomings. Generally according to specific circumstances, specific analysis of specific choices.

- Q:What are the different methods of pipe cutting for steel pipes?

- There exists a variety of techniques for cutting steel pipes, each tailored to specific circumstances and demands. Some of the most prevalent techniques are as follows: 1. Manual Pipe Cutters: These handheld tools are frequently employed for cutting smaller steel pipes. They typically feature a rotating cutting wheel that gradually creates a groove until the pipe is severed. Portable and relatively user-friendly, manual pipe cutters are suitable for on-site cutting tasks. 2. Hacksaw: The use of a hacksaw is a traditional and cost-effective means of cutting steel pipes. This method requires physical exertion and time; however, it can effectively cut pipes with smaller diameters. It is crucial to use a fine-toothed blade and apply steady pressure to ensure a clean and precise cut. 3. Reciprocating Saw: Also known as a sawzall, the reciprocating saw is a power tool that employs a back-and-forth cutting motion to swiftly and efficiently cut through steel pipes. These versatile saws can accommodate different types of blades to handle various pipe sizes and thicknesses. 4. Band Saw: Band saws are commonly employed in industrial settings for the purpose of cutting large steel pipes. These saws feature a continuous loop of teethed metal blade that moves on wheels, enabling precise and rapid cutting. Band saws are ideal for cutting large-diameter pipes and can be operated manually or fully automated for high-volume cutting tasks. 5. Pipe Cutting Machines: Pipe cutting machines are often utilized to achieve precise and consistent cuts. These machines are designed to cut steel pipes swiftly and accurately, making them suitable for large-scale industrial applications. Depending on the machine and requirements, various cutting methods like abrasive cutting, flame cutting, or plasma cutting can be employed. It is important to note that the selection of a pipe cutting method depends on factors such as pipe diameter, thickness, location, precision requirements, and available resources. It is imperative to adhere to proper safety precautions when working with any cutting method to prevent injury or damage to the pipes.

- Q:How do you calculate the maximum allowable deflection for steel pipes?

- To calculate the maximum allowable deflection for steel pipes, you need to consider various factors such as the pipe diameter, material properties, support conditions, and the desired level of deflection. The maximum allowable deflection is typically determined based on industry standards and codes. One commonly used method for calculating the maximum allowable deflection is based on the pipe's span-to-diameter ratio (L/D ratio). The L/D ratio is the ratio of the pipe's span (distance between supports) to its diameter. Several industry codes provide guidelines on the maximum allowable deflection based on the L/D ratio. For example, the American Society of Mechanical Engineers (ASME) B31.1 Power Piping Code suggests that for carbon steel pipes, the maximum allowable deflection should not exceed 3% of the pipe's span for an L/D ratio of 100 or less. However, for higher L/D ratios, the deflection limit decreases, ensuring the pipe's stability and structural integrity. To calculate the maximum allowable deflection using the L/D ratio method, you would first determine the L/D ratio based on the span and diameter of the pipe. Then, referring to the applicable code or standard, you can find the corresponding maximum allowable deflection limit. It is important to note that other factors such as the pipe material's yield strength, wall thickness, and the type of loading (e.g., dead load, live load) also influence the maximum allowable deflection. Therefore, it is crucial to consult the relevant industry standards, codes, and engineering principles to accurately calculate the maximum allowable deflection for steel pipes.

- Q:How are steel pipes used in the automotive manufacturing industry?

- Steel pipes are commonly used in the automotive manufacturing industry for various purposes such as exhaust systems, fuel lines, and structural components. They provide durability, strength, and resistance to high temperatures, making them ideal for these applications.

- Q:Do steel pipes expand or contract with temperature changes?

- Steel pipes expand when subjected to an increase in temperature and contract when exposed to a decrease in temperature. This phenomenon is a result of the thermal expansion and contraction properties of steel, which is a characteristic of most materials. When steel pipes are heated, the molecules within the metal gain energy and vibrate more vigorously, causing them to move apart and expand in size. Conversely, when the temperature of the steel pipes decreases, the molecules lose energy and move closer together, resulting in a contraction or shrinkage in size. It is important to consider these thermal expansion and contraction properties of steel pipes when designing and installing them, as failure to account for these changes may lead to structural damage, leaks, or other issues.

- Q:How are steel pipes cleaned and maintained?

- Steel pipes are cleaned and maintained through a combination of mechanical and chemical methods. Mechanical cleaning involves removing any loose debris or scale using tools like wire brushes or high-pressure water jets. Chemical cleaning may be used to dissolve any stubborn deposits or corrosion using suitable solvents or acids. Regular inspection and maintenance are essential to identify and address any potential issues such as leaks, rust, or structural damage. Coatings, such as paint or anti-corrosion materials, are often applied to protect steel pipes from environmental factors and extend their lifespan.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

carbon seamless steel pipe/ASTM A53 Grade B Seamless Pipes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords