Calcined Petroleum Coke as Injection Coke for Steel Plants wthin

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20.2

- Supply Capability:

- 1012 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Intrduction

Carbon additive to ningxia production of anthracite as raw material, after washing, crushing, high temperature calcination, filter, etc. Craft refined and become.This is after the anthracite calcination generated high carbon content and low volatile component of the new product, is an ideal raw material to make steel.

Calcined Petroleum Coke comes from delayed coke which extracted from oil refinery. Although Calcined Petroleum Coke contains a little bit higher level of sulfur and nitrogen than pitch coke, the price advantage still makes it widely used during steel-making and founding as a kind of carbon additive/carburant.

Features

In the smelting process for reducing agent. Performance: replace the traditional oil carbon additive, decrease the cost of steelmaking. Features: low ash. low sulfur,low phosphorus, high calorific value. High ratio resistance,high mechanical strength,high chemistry activity. It is mainly used for metallurgy reductant inoculants, casting, refractory materials, machinery, electronics and other fields.Good quality

1) high absorption rate, it can be absorbed up to 90%.

2) absorbed more quickly than other carbon additive; no residue remains in furnace.

3) low Sulfur, the lowest can reach below 0.20%; low nitrogen, normally below 200ppm (0.02%)

Specifications

CPC | |||

F.C.% | 98.5MIN | 98.5MIN | 98MIN |

ASH % | 0.8MAX | 0.8MAX | 1MAX |

V.M.% | 0.7 MAX | 0.7 MAX | 1 MAX |

SULFUR % | 0. 5MAX | 0. 7MAX | 1MAX |

MOISTURE % | 0.5MAX | 0.5MAX | 1MAX |

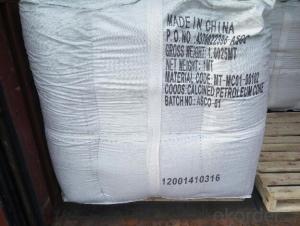

Pictures

FAQ:

(1)CPC could be as fuel

Petroleum coke is a material relatively low in cost and high in heat value and carbon content with good chemical stability, making it an efficient and costeffective fuel for producing metal, brick and related products.

(2)CPC could be as Graphite Electrodes

Graphite can be produced from lowsulfur needle petroleum coke, which must be heated above 5,432 degrees Fahrenheit.

(3)CPC could be as Anodes

Calcined petroleum coke, often low in sulfur and metallic impurities, is used to make anodes for

the smelting industry.Calcined petroleum coke is mixed with coal tar pitch in the production of

anodes.

- Q:What are the properties of carbon fibers?

- Carbon fibers are a unique and versatile material with several notable properties. One of their most significant properties is their exceptional strength-to-weight ratio. Carbon fibers are incredibly strong, often surpassing the strength of steel, while also being significantly lighter. This property makes carbon fibers ideal for applications where high strength and low weight are crucial, such as aerospace and automotive industries. Another important property of carbon fibers is their stiffness. They exhibit high stiffness, which means they have minimal deformation under applied loads. This property is beneficial in applications where rigidity and stability are required, such as in the construction of sporting goods like tennis rackets or golf clubs. Carbon fibers also possess excellent chemical resistance. They are highly resistant to chemical corrosion, making them suitable for use in harsh environments where exposure to chemicals or corrosive substances is a concern. This property makes carbon fibers a preferred choice for applications in the chemical industry or offshore structures. Furthermore, carbon fibers have a low thermal expansion coefficient, meaning they do not expand significantly when exposed to heat. This property makes them useful in applications where thermal stability is crucial, such as in the manufacturing of high-temperature components like turbine blades or heat shields. Additionally, carbon fibers exhibit excellent fatigue resistance, allowing them to withstand repeated loading and unloading cycles without significant damage. This property is particularly advantageous in applications subjected to cyclic or dynamic stresses, such as in the construction of sports equipment or aerospace structures. Lastly, carbon fibers have excellent electrical conductivity. They can conduct electricity efficiently, making them suitable for applications where electrical conductivity is required, such as in the aerospace industry for lightning strike protection or in the manufacture of electronic devices. Overall, the properties of carbon fibers, including their high strength-to-weight ratio, stiffness, chemical resistance, low thermal expansion, fatigue resistance, and electrical conductivity, make them a highly desirable and sought-after material in various industries.

- Q:What is carbon black dye?

- Carbon black dye is a pigment derived from the incomplete combustion of hydrocarbons, commonly used in various industries, including the production of inks, plastics, rubber, and coatings.

- Q:Just come out to work, do activated carbon, often see carbon materials and carbon materials, I do not know what the difference, trouble you!

- Carbon materials are usually specified, especially carbon and graphite materialsCarbon material is a broad carbon containing materialAbove.

- Q:What are the impacts of carbon emissions on the stability of grasslands?

- Carbon emissions have significant impacts on the stability of grasslands. As carbon dioxide (CO2) is released into the atmosphere, it contributes to the greenhouse effect, leading to global warming. This increase in temperature has several detrimental effects on grasslands. Firstly, higher temperatures can disrupt the balance of grassland ecosystems. Many grassland species have specific temperature requirements for growth and reproduction. As temperatures rise, these species may struggle to adapt, leading to a decline in their populations. This can disrupt the overall biodiversity and ecological stability of grasslands. Secondly, global warming can alter precipitation patterns, leading to changes in water availability in grasslands. Reduced rainfall or increased evaporation can result in drought conditions, making it difficult for grasses to grow and thrive. This can lead to the desertification of grasslands, transforming them into barren areas devoid of plant life. Furthermore, carbon emissions contribute to the acidification of the oceans, which can indirectly impact grasslands. Acidic ocean waters affect marine organisms, including those responsible for generating nutrients that are carried by winds to coastal and inland grasslands. If these nutrient sources decline, grasslands may experience reduced fertility and productivity, affecting the stability of these ecosystems. Lastly, carbon emissions can also exacerbate the frequency and intensity of wildfires. Grasslands are naturally adapted to periodic fires, which play a crucial role in maintaining biodiversity and regulating plant populations. However, the increase in carbon dioxide levels can fuel more intense and frequent wildfires, which can destroy grasslands and make their recovery more challenging. In conclusion, carbon emissions have multiple negative impacts on the stability of grasslands. They disrupt the balance of grassland ecosystems, alter precipitation patterns, contribute to ocean acidification affecting nutrient sources, and increase the risk of wildfires. These effects can lead to biodiversity loss, desertification, reduced fertility, and overall instability in grassland ecosystems. It is crucial to reduce carbon emissions and mitigate the impacts of global warming to ensure the long-term stability and preservation of grasslands.

- Q:What are the impacts of carbon emissions on biodiversity?

- Carbon emissions have significant impacts on biodiversity. Increased levels of carbon dioxide in the atmosphere contribute to climate change, which disrupts ecosystems and threatens biodiversity. Rising temperatures, altered precipitation patterns, and more frequent extreme weather events can lead to habitat loss, shifts in species distribution, and reduced reproductive success. Moreover, ocean acidification resulting from carbon emissions poses a threat to marine ecosystems, affecting coral reefs and other vulnerable species. Overall, carbon emissions have detrimental effects on biodiversity, potentially leading to the extinction of numerous species and the destabilization of ecosystems.

- Q:What are the impacts of carbon emissions on coral reefs?

- The impacts of carbon emissions on coral reefs are significant and detrimental. Increased levels of carbon dioxide in the atmosphere lead to ocean acidification, which disrupts the delicate balance of the reef ecosystem. Acidic conditions hinder the ability of corals to build their calcium carbonate skeletons, making them more vulnerable to erosion and bleaching. Additionally, rising temperatures caused by carbon emissions contribute to coral bleaching events, where corals expel their symbiotic algae, leading to their eventual death. Overall, carbon emissions pose a major threat to coral reefs, jeopardizing their biodiversity and ecological functions.

- Q:What are the impacts of carbon emissions on glacier retreat?

- Carbon emissions have a significant impact on glacier retreat. As carbon dioxide and other greenhouse gases are released into the atmosphere through human activities, such as burning fossil fuels and deforestation, they contribute to global warming. This increase in global temperatures has a direct effect on glaciers. Glaciers are large bodies of ice that form over long periods of time from accumulated snowfall. They act as natural reservoirs of freshwater, providing a crucial source of drinking water to millions of people around the world. However, as the Earth's temperature rises due to carbon emissions, glaciers begin to melt at an accelerated rate. The warming climate causes glaciers to lose more ice through melting than they gain through snowfall. This leads to a net loss of ice, resulting in glacier retreat. As glaciers retreat, they not only shrink in size but also become thinner. This diminishes their ability to store water, affecting water availability in regions that rely on glacial meltwater for drinking, irrigation, and hydropower generation. Furthermore, glacier retreat has far-reaching consequences for ecosystems and biodiversity. Glaciers provide unique habitats for various species, including plants, animals, and microorganisms, which have adapted to survive in these extreme environments. As glaciers disappear, these species are forced to adapt or migrate to other areas, disrupting the delicate balance of ecosystems. The impacts of glacier retreat are not limited to local or regional scales. Glacial meltwater contributes to rivers and lakes, ensuring a consistent flow of water throughout the year. As glaciers shrink, this flow decreases, leading to water scarcity during dry seasons. This poses a threat to agriculture, urban water supplies, and the overall sustainability of ecosystems that rely on a stable water supply. Additionally, the loss of glaciers contributes to rising sea levels. When glaciers melt, the water they release flows into the oceans, causing them to expand. This exacerbates coastal erosion, increases the risk of flooding in low-lying areas, and threatens coastal communities and infrastructure. In summary, carbon emissions have a profound impact on glacier retreat. The resulting global warming accelerates the melting of glaciers, leading to water scarcity, biodiversity loss, increased sea levels, and various environmental and socio-economic consequences. It is crucial to address carbon emissions and take steps to mitigate climate change to preserve these vital ice formations and the ecosystems and communities that depend on them.

- Q:What are the effects of ocean acidification on marine life?

- Ocean acidification is a significant issue that poses numerous detrimental effects on marine life. The primary cause of this phenomenon is the increase in carbon dioxide (CO2) emissions, which are absorbed by the oceans, leading to a decrease in pH levels. As the ocean becomes more acidic, it has profound consequences for various marine organisms and ecosystems. One of the most vulnerable groups impacted by ocean acidification is shell-forming organisms, such as corals, mollusks, and some types of plankton. The increasing acidity reduces the availability of carbonate ions, a vital component for these organisms to build and maintain their shells or skeletons. As a result, their growth and development are hindered, making them more susceptible to predation and extinction. This not only affects these individual species but also disrupts the entire food web, as they serve as a crucial food source for many other marine organisms. Furthermore, ocean acidification has adverse effects on various marine organisms' physiology and behavior. Studies have shown that it can impair the ability of fish to detect predators, find food, and navigate, which can lead to reduced survival rates and altered migratory patterns. Additionally, acidification can disrupt reproductive processes, such as the growth and survival of fish larvae, leading to population declines and reduced biodiversity. Coral reefs, often referred to as the "rainforests of the sea," are particularly vulnerable to ocean acidification. The increased acidity inhibits the calcification process essential for coral growth, making them more susceptible to bleaching and death. As coral reefs provide crucial habitats for numerous marine species, their decline would have cascading effects on the entire ecosystem. Lastly, ocean acidification also impacts the balance of marine ecosystems by altering the composition and abundance of various species. Some organisms, such as certain types of algae, may actually benefit from increased CO2 levels and thrive, leading to an imbalance in the ecosystem. This can result in the dominance of certain species, negatively impacting the overall biodiversity and stability of the marine environment. In conclusion, ocean acidification poses significant threats to marine life. It disrupts the growth and development of shell-forming organisms, impairs the physiology and behavior of various marine species, damages coral reefs, and alters the composition of marine ecosystems. Addressing this issue is crucial to protect marine biodiversity, sustain fisheries, and maintain the overall health of our oceans.

- Q:How does carbon impact the growth and development of plants?

- Carbon is an essential element for the growth and development of plants. It plays a crucial role in the process of photosynthesis, which is how plants convert sunlight into energy. During photosynthesis, plants absorb carbon dioxide from the atmosphere and use it, along with water, to produce glucose and oxygen. Glucose is the primary source of energy for plant growth and is utilized to build various molecules such as cellulose, proteins, and lipids. In addition to being a key component of sugars, carbon is also a vital element in the structure of plant cells. It forms the backbone of complex organic compounds, including carbohydrates, proteins, nucleic acids, and lipids. These compounds are essential for the growth and development of plants, as they are involved in processes like cell division, cell elongation, and the formation of new tissues. Furthermore, carbon is involved in regulating various physiological and metabolic processes in plants. It influences the opening and closing of stomata, the tiny pores on the surface of leaves, which control the uptake of carbon dioxide and the release of oxygen and water vapor. Carbon also affects the production of plant hormones, which are responsible for regulating growth, development, and responses to environmental stimuli. However, excessive carbon dioxide in the atmosphere, resulting from human activities such as burning fossil fuels, can have negative impacts on plants. Elevated levels of carbon dioxide can lead to changes in plant physiology, including increased photosynthesis rates and decreased stomatal conductance. These changes can affect the nutritional quality of plants, alter their interactions with pests and diseases, and disrupt ecosystems. In summary, carbon is essential for the growth and development of plants as it is a key component of sugars, organic compounds, and structural elements in plant cells. It is involved in processes such as photosynthesis, cell division, and the regulation of physiological and metabolic functions. However, changes in atmospheric carbon dioxide levels can have both positive and negative impacts on plants, emphasizing the need for sustainable practices to ensure the future growth and development of plant species.

- Q:How is carbon used in the production of lubricants?

- Carbon is used in the production of lubricants as it forms the base of many lubricant formulations. Carbon compounds, such as hydrocarbons, are used as the primary ingredient in lubricants to provide lubricating properties. These compounds help reduce friction and wear between moving parts, thus improving the efficiency and lifespan of machinery and equipment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Calcined Petroleum Coke as Injection Coke for Steel Plants wthin

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20.2

- Supply Capability:

- 1012 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords