Butterfly Valve DN80 Turbine Type Hand Wheel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

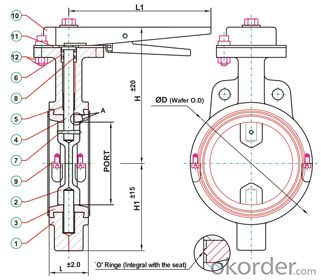

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q:What is the medium flow rate when the centerline butterfly valve is fully open?

- The pressure test of the central butterfly valve is carried out at each station.Basis:1) GB/T12238-2008 flange and clamp connection elastic seal butterfly valveRules: butterfly valve must be carried out by factory inspection and testing, inspection qualified before leaving the factory.2) CJ/T 261-2007, butterfly valves for water supply and drainageRules: each product shall be inspected by factory and quality inspection department.

- Q:Which is more expensive, gate valve or butterfly valve?

- Gate valves of the same material and specifications are much more expensive. The weight of the gate valve is much heavier than that of the butterfly valve.

- Q:How can the flange butterfly valve be installed on the pipe?

- It is better to install it vertically or horizontally, and leave some space for maintenance

- Q:Check valve; flexible joint `; installation order of electric butterfly valve

- It is better to make an elastic hanger.In order to prevent the generation of water hammer when the pump stops the damage to the rubber head, should be immediately set rubber head pump outlet, the gate valve and the check valve is not a very convincing reason to decide the order, custom order rubber head, check valve, electric butterfly valve.

- Q:What do D71, D371 and D341 represent in butterfly valves?

- D71 is a handle to clip butterfly valveD371 is a turbine to clip butterfly valveD341 is a manually operated double flanged butterfly valve

- Q:What are the classification criteria for pneumatic butterfly valves?

- Pneumatic flange butterfly valve, pneumatic flange butterfly valve, this product is made up of rubber sealed butterfly valve and carbon steel or stainless steel valve plate and valve stem. Suitable temperature is less than or equal to 80 to 120 DEG C, such as food, chemical, petroleum, electric power, textile, papermaking, water supply and drainage, gas pipes to regulate the flow and closure of the role of media.Pneumatic control valve is a valve (valve plate) around the rotating fixed axis perpendicular to the channel, which is composed of double or single acting piston (spring reset type) pneumatic actuator and butterfly valve, a rotary type high performance adjust or cut off valves, electric, pneumatic valve positioner or electromagnetic valve, air filter regulator, limit switch (valve position), can be realized on the fluid medium in the pipeline and process to adjust the proportion of the two cut off control, automatic control to achieve the parameters of the fluid flow, pressure, temperature, liquid level etc..

- Q:Where are the exhaust valves, mud valves and butterfly valves?

- The exhaust valve is used for the heating of the independent heating system, central heating system, heating boiler, central air conditioning, floor heating and solar heating system.Mud valve, also known as cover valve, commonly used in urban water plants, sewage treatment plants sedimentation tank bottom discharge sludge.Butterfly valve used in furnace, coal gas, natural gas, liquefied petroleum gas, city gas, hot and cold air, chemical smelting and power generation environmental protection engineering system, conveying a variety of corrosive and non corrosive media pipeline, used to adjust and cut off the media flow.

- Q:What is the principle of butterfly valve and check valve? Any difference?

- Crown valve pressButterfly valve is butterfly valveThe check valve is a check valveButterfly valve is mainly switching functionThe check valve mainly stops the pipe from flowing backwardsThe two can only be said to be valvesThe others are different

- Q:The difference between butterfly valve and gate valve

- Butterfly valve role, butterfly valve is used to open and close disk type reciprocating rotation of about 90 degrees to open, close or adjust the flow of a medium valve. The butterfly valve has the advantages of simple structure, small volume, light weight, material consumption, installation of small size, the driving performance of torque is small, simple operation, rapid, high chemical corrosion, and can also have good flow control function and closure characteristics, the use of butterfly valve is very extensive.

- Q:The difference between the directly buried gate and the flange valve and butterfly valve

- The flange gate valve is stable and reliable when used in the pipeline, so the flange gate valve is used on the high pressure pipeline.Butterfly valve refers to the closure of parts (valve or butterfly plate) as the disk, around the valve shaft to achieve rotation and closing of a valve, the main cut off on the pipe and throttling role. Butterfly valve headstock is a disc shaped disc, in the valve body around its own axis of rotation, so as to achieve the purpose of opening or closing or regulation. Butterfly valve used in furnace, coal gas, natural gas, liquefied petroleum gas, city gas, hot and cold air, chemical smelting and power generation environmental protection engineering system, conveying a variety of corrosive and non corrosive media pipeline, used to adjust and cut off the media flow.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Butterfly Valve DN80 Turbine Type Hand Wheel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products