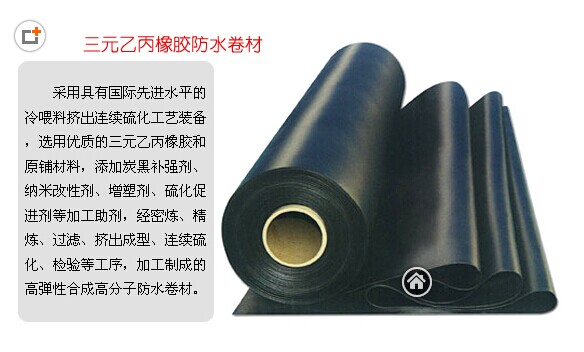

Black EPDM Rubber Flat Roofing Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Membrane

Specifications

ASTM Standard D-7465,D-4367

thickness:1.2mm,width:4m,length:20m

eco-friendly

widely exported to Australia, UK,Argentina etc.

1.2mmEPDM rubber flat roofing material.

EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material. EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is designed for waterproofing of exposed and non-exposed applications. EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

Features

Excellent weatherability, durability and size stability

Good adaptability to high and low temperature, UV resistant and anti-corrosion

High tensilestrength and good elongation, accommodating substrate movement

Easy installation, environment friengly

Good rooting penetration resistance

Service life up to 50 years

Applications

Subways, tunnels, roofs, basement

Industrial and civil building waterproofing, like water reservior, bridge, dam, etc.

Geosynthetic liner for swimming pool, channels, irrigation system

Especially suitale for projects with high requirements in durability, anti-corrosion and deformation

Application Method:

1. Make sure the roof deck smooth,clean and dry(Moisture<9%),then apply the surface of roof deck homogeneously with a kind bitumen paint till dry to start application.

2. There are two methods in application:

One way is by heating and melting method---Heat the polyethylene film of the membrane and roof deck surface by heating and melting method to be nearly melted(not flowing),then install the membrane fully bonded to the roof deck with overlaps of 5-10cm.

The other way is by cold adhesive method---Pour the cold adhesive homogeneously on the roof deck then roll the membrane to install it to be fully sticked to roof deck.

By heating and melting method and by cold adhesive can be used in alternation in application as requested.

3. After application,a full serious inspection is required to make sure no air bubble,no fold,no falling away etc to guarantee the waterproof life.

Attentions for Construction:

Construction shall not be carried out in rain, snow or over 5 degree wind weather; There shall be sufficient safety protective facilities in construction site, place firefighting devices according to stipulations

1. Clean the substrate using broom or high pressure dusty cleaner

2. Apply primer

3. Heat the membrane bottom using a high temperature flame gun

4. Push forward while the primer and membrane oil melted

5. Use a roller to push hard the membrane surface to ensure it stick firmly

Some photos:

- Q:Can a waterproofing membrane be used for a water tank liner?

- Yes, a waterproofing membrane can be used for a water tank liner. Waterproofing membranes are specifically designed to prevent water penetration and can be applied to a variety of surfaces, including concrete, metal, and other materials commonly used in water tank construction. These membranes create a barrier that prevents leaks, cracks, and other forms of water damage, ensuring the integrity and longevity of the water tank. Additionally, waterproofing membranes are typically flexible, allowing them to conform to the shape of the tank and accommodate any movement or settlement that may occur. It is important, however, to select a waterproofing membrane that is specifically designed for water tank applications to ensure optimal performance and durability.

- Q:Can a waterproofing membrane be used on crawl spaces?

- Yes, a waterproofing membrane can be used on crawl spaces. It can effectively prevent moisture from seeping into the crawl space, protecting it from water damage and potential mold or mildew growth.

- Q:Can a waterproofing membrane be used for bridge decks?

- Yes, a waterproofing membrane can be used for bridge decks. Bridge decks are exposed to various weather conditions, including rain, snow, and humidity, which can cause damage and deterioration over time. Therefore, applying a waterproofing membrane on the bridge deck surface can help protect it from water infiltration and moisture-related issues such as corrosion of steel reinforcements. Waterproofing membranes are specifically designed to create a barrier that prevents water from penetrating the surface. They are typically made from materials such as modified bitumen, thermoplastic, or liquid-applied coatings. These membranes are applied to the bridge deck surface, creating a seamless and watertight layer that prevents water from seeping into the deck structure. In addition to preventing water infiltration, waterproofing membranes can also provide additional benefits for bridge decks. They can help reduce the risk of freeze-thaw damage, protect against chemical attacks from de-icing salts or pollutants, and increase the overall durability and lifespan of the bridge deck. It is important to note that the selection of the appropriate waterproofing membrane for a bridge deck depends on various factors such as the type of bridge, traffic conditions, climate, and expected service life. Therefore, it is essential to consult with structural engineers and waterproofing specialists to choose the most suitable membrane system for a specific bridge deck project.

- Q:Can a waterproofing membrane be used for a stadium roof?

- Yes, a waterproofing membrane can be used for a stadium roof. Waterproofing membranes are designed to provide a barrier against water infiltration and protect the underlying structure from moisture damage. Using a waterproofing membrane on a stadium roof can help prevent leaks and ensure the longevity of the roof.

- Q:Can a waterproofing membrane be used in swimming pools or water features?

- Yes, a waterproofing membrane can be used in swimming pools or water features. Waterproofing membranes are specifically designed to prevent water leakage and can effectively seal and protect the surfaces of pools and water features from water damage.

- Q:Are there any environmental considerations when using a waterproofing membrane?

- Yes, there are several environmental considerations when using a waterproofing membrane. One of the main concerns is the potential for harmful chemicals or materials to be used in the production of the membrane. Some waterproofing membranes may contain toxic substances such as volatile organic compounds (VOCs) or heavy metals, which can have detrimental effects on human health and the environment. Another consideration is the disposal of the membrane once it reaches the end of its life cycle. Many waterproofing membranes are not biodegradable and can contribute to landfill waste. Improper disposal can lead to environmental pollution and harm to ecosystems. Additionally, the production of waterproofing membranes often requires energy-intensive processes and the extraction of non-renewable resources. This can contribute to greenhouse gas emissions and the depletion of natural resources. To mitigate these environmental concerns, it is important to choose waterproofing membranes that have been manufactured using eco-friendly materials and processes. Look for products that are labeled as low VOC or free from hazardous substances. Additionally, consider using membranes that are recyclable or made from recycled materials to reduce waste generation. Proper disposal of the membrane at the end of its life cycle is also crucial, and options such as recycling or repurposing should be explored. Overall, it is essential to consider the environmental impact of waterproofing membranes and choose products and practices that minimize harm to the environment and promote sustainability.

- Q:Can a waterproofing membrane be used for train platforms?

- Train platforms can indeed benefit from the application of a waterproofing membrane. Given their exposure to different weather conditions like rain and snow, it is important to address potential water damage and deterioration over time. One effective method is to install a waterproofing membrane on the surface of the platform. This protective barrier prevents water from seeping through and causing harm to the underlying structure. Consequently, this approach not only prolongs the platform's lifespan but also reduces maintenance costs and ensures the safety of passengers and personnel. In addition, the use of a waterproofing membrane can help prevent the growth of mold and mildew, which can negatively impact the health of those using the train platform. All in all, utilizing a waterproofing membrane on train platforms proves to be a practical and efficient solution for safeguarding against water damage and maintaining the infrastructure's longevity.

- Q:Does a waterproofing membrane require any special considerations for installation in seismic zones?

- Yes, a waterproofing membrane does require special considerations for installation in seismic zones. Seismic zones are prone to earthquakes and ground movements, which can cause significant stress and strain on the building structure. When installing a waterproofing membrane in such areas, it is crucial to ensure that it can withstand the potential movements and vibrations caused by seismic activities. Some of the special considerations for installing a waterproofing membrane in seismic zones include: 1. Flexibility: The membrane should have sufficient flexibility to accommodate the movement of the building structure during an earthquake. It should be able to stretch, contract, and withstand dynamic forces without tearing or losing its waterproofing properties. 2. Compatibility: The waterproofing membrane should be compatible with the building materials and systems used in seismic zones. It is important to select a membrane that can bond well with the substrate and other construction components to create a seamless and robust waterproofing system. 3. Reinforcement: In high seismic areas, it is recommended to reinforce the waterproofing membrane with additional layers or reinforcements. This can be done by adding a fabric or mesh layer to enhance the membrane's tensile strength and resistance to tearing caused by seismic movements. 4. Proper installation techniques: The installation of the waterproofing membrane in seismic zones should follow specific guidelines and techniques to ensure its effectiveness. It may involve using specific adhesives, primers, or mechanical fastening systems to secure the membrane properly. 5. Quality control: Regular inspections and quality control measures should be implemented during and after the installation process. This helps to identify any potential issues or deficiencies in the waterproofing system, allowing for prompt repairs or adjustments to be made. By addressing these special considerations, the installation of a waterproofing membrane in seismic zones can help protect the building structure from water intrusion and potential damage caused by earthquakes. Consulting with experienced professionals and following industry standards and guidelines is crucial to ensure a successful installation in these challenging environments.

- Q:Can a waterproofing membrane be used on copper surfaces?

- Yes, a waterproofing membrane can be used on copper surfaces.

- Q:Can a waterproofing membrane be used for plant rooms?

- Yes, a waterproofing membrane can be used for plant rooms. Plant rooms often house machinery and equipment that require protection from water and moisture. Using a waterproofing membrane can help prevent water damage to the plant room and the equipment inside. It creates a protective barrier that keeps water from penetrating the walls, floors, and ceilings of the plant room. This can be especially important in areas where there is a higher risk of water leaks or condensation. Waterproofing membranes are designed to withstand various environmental conditions and can provide long-lasting protection for plant rooms.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Black EPDM Rubber Flat Roofing Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords