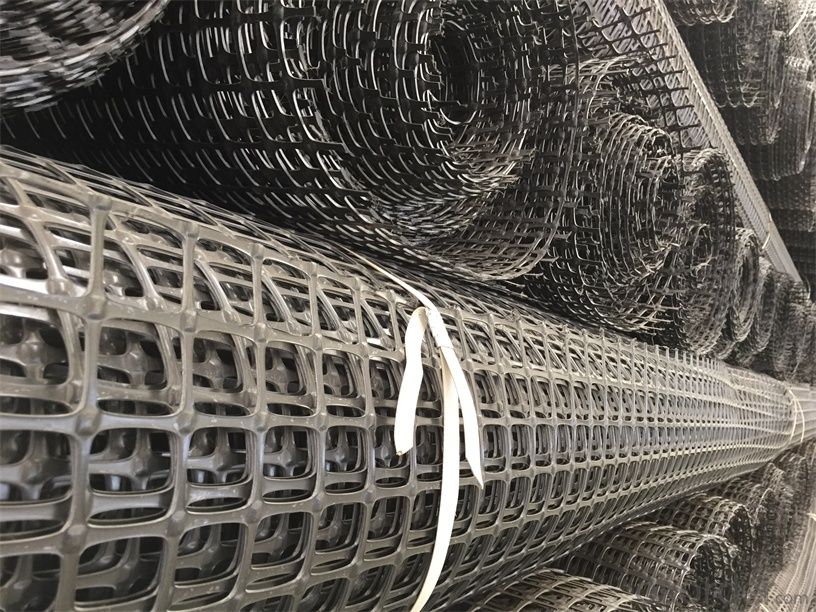

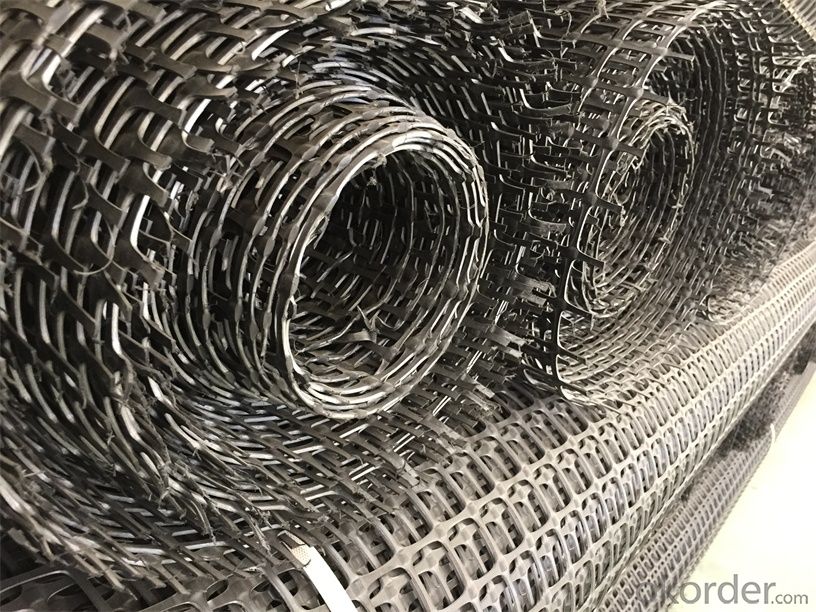

Bitumen Coated FiberglassGeogrid with High Tensile Strength Suitable for Different Market

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Introduction:

Fiberglass geogrid is a kind of planar mesh material using alkali-free fiberglass yarn as base body and then coated with high quality modified asphalt. It is warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant. Moreover, the composite property of coating with asphalt makes full protection of the fiberglass matrix and greatly improves its wear and shear resistance. All the advantageous functions make the product have a good performance in pavement strengthening, track cracking and solving difficulties of strengthening the bituminous pavement.

Fiberglass Geogrid Features:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications | PET20-20 | PET30-30 | PET40-40 | PET50-50 | PET80-80 | PET100-100 | PET120-120 |

Elongation(%) | 10%~15% | ||||||

Vert Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Horiz Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Grid(mm) | 12.5×12.5 20×20 24.5×24.5 | ||||||

Width(m) | 1—6 | ||||||

Fiberglass Geogrid Application:

1. Road surface asphalt overlay construction engineering; Asphalt layers

reinforcement.

2. Converting old cement concrete road into composite road; Restraining

reflection cracking caused by block shrinkage.

3. Road extension; Preventing and controlling the cracking caused by new

and old combination and uneven settlement.

4. Treatment of the conjunction between tunnel and bridge or foundation.

Packaging & Shipping:

FAQ:

1. How to order your geogrid ?

a) Tensile strength in warp & weft direction

b) Grid size

c) Roll Width and length

d) Quantity

2. What is the Payment term?

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

Welcome to send your inquiry to us, and if you have any question, we can also help you.

- Q:What is the distance between the waterproof plate and the top of the tunnel? What are the relevant provisions of this specification?

- Geotextile, composite geomembrane, bentonite waterproof blanket, a new type of three-dimensional mesh pad, geocell and other engineering materials

- Q:Can geogrids be used in environmental containment systems?

- Yes, geogrids can be used in environmental containment systems. They are often employed as reinforcement materials in various containment applications such as landfills, ponds, lagoons, and waste storage areas. Geogrids help enhance the stability and integrity of the containment system by providing structural support and preventing soil erosion. They are designed to withstand heavy loads and provide long-term durability, making them suitable for use in environmental containment systems.

- Q:What are the two levels of widening of the geogrid in the asphalt concrete road?

- If it is other material should be placed in the ground inside, thank you.

- Q:Are geogrids suitable for use in reinforced slopes?

- Yes, geogrids are suitable for use in reinforced slopes. Geogrids are highly effective in stabilizing and reinforcing slopes by providing increased tensile strength and distributing loads more evenly. They enhance the stability of the soil, prevent erosion, and can be used in various types of reinforced slope applications, making them a suitable choice for such projects.

- Q:How do geogrids help in reducing soil compaction?

- Geogrids help in reducing soil compaction by providing reinforcement and support to the soil structure. They distribute the load more evenly, reducing the pressure on the soil particles and preventing excessive compaction. This helps to maintain the soil's porosity, allowing for better water infiltration and root growth. Additionally, geogrids can improve the stability of the soil, preventing it from settling and compacting under heavy loads.

- Q:What is the lifespan of geogrids in typical applications?

- The lifespan of geogrids in typical applications can vary depending on various factors such as the specific type and quality of the geogrid, the environmental conditions, and the level of stress or load applied to the geogrid. However, in general, geogrids are designed to have a long lifespan ranging from 20 to 50 years or even more in some cases. Regular maintenance and inspection can help extend the lifespan of geogrids and ensure their continued effectiveness in their intended applications.

- Q:How do geogrids prevent soil erosion?

- Geogrids prevent soil erosion by providing reinforcement to the soil, increasing its stability and resistance to external forces such as water flow or wind. The geogrids are typically made of high-strength materials and are placed within the soil, creating a network of interlocking structures that enhance the soil's load-bearing capacity. This prevents the soil from being easily displaced, maintaining its integrity and reducing erosion.

- Q:Want to know what is the advantage of unidirectional polyester geogrid and two-way existence? What are the differences between the two?For example, function, cost, construction

- First talk to the function of it, compared with the similar functions, There are both advantages and disadvantages., but the cost of bidirectional geogrid is more expensive! Construction is the same! The difference lies in the cost! Thank you

- Q:Are geogrids suitable for use in agricultural applications?

- Yes, geogrids are suitable for use in agricultural applications. They can be used to reinforce soil, prevent erosion, improve drainage, and provide stability for roads and paths in agricultural fields. Additionally, geogrids can help in promoting healthy plant growth by enhancing soil structure and preventing compaction. Overall, geogrids offer numerous benefits for agricultural applications and can contribute to sustainable farming practices.

- Q:Why steel plastic geogrid in the test, will choose to peel out a single wire test? What are the causes and sources of this method?

- Have you ever studied probability statistics?

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Bitumen Coated FiberglassGeogrid with High Tensile Strength Suitable for Different Market

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords