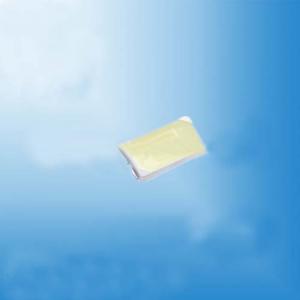

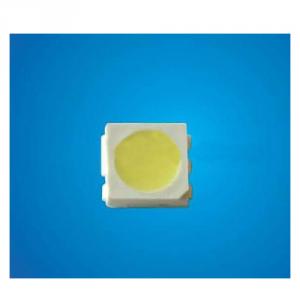

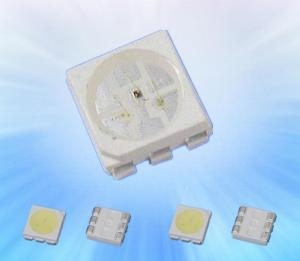

Best Price Bridgelux Chip White 150Ma 0.5W SMD LED 5730

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

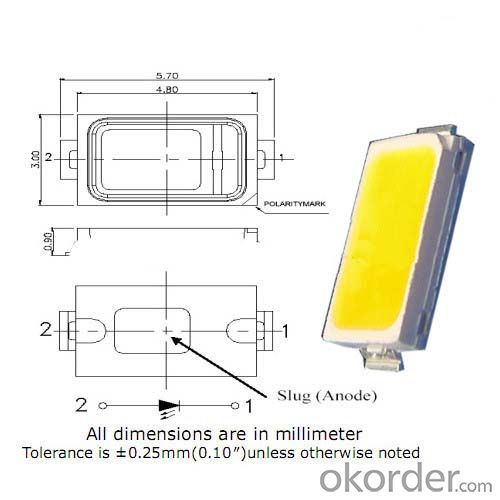

best price bridge lux chip white 150mA 0.5w smd led 5730

Production Description

|

2. Storage

2.1 It is recommended to store the products in the following conditions

Humidity: 60% R.H. Max.

Temperature: 5°C~30°C(41°F~86°F)

2.2 Shelf life in sealed bag: 12 month at <5°C~30°C and <30% R.H. after the package is opened,

the products should be used within 24hr s or they should be kept stored at<20% R.H. with zip-lock sealed.

3. Vision Advisory Claim

Users should be cautioned not to stare at the light of this LED product. The bright light can damage the eye.

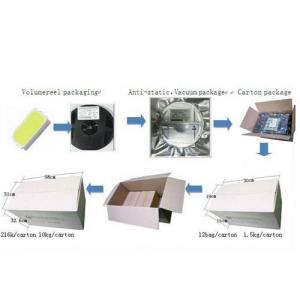

Packaging & Shipping

Packing:

Standard packing inside, cartons outside

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

Air freight | 3-10 business days |

By Sea | 30-40 business days |

1. 3-5 business days for Sample Orders; 7-30 business days for Bulk Orders for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

About Us

As a High-tech manufacture of LED company, we have more than 10 years' experiences. SHENZHEN CHENGHUIGUANG TECHNOLOGY CO,.LTD has a strong team of professional staff to handle all phases of production from research and development, to quality control,technical support and after services. And all kinds of the products are practiced accroding to ISO9001-2000 system.

Our Services

1. We have a special R&D center team, which can solve any problems for clients.

2. After sale service can help customers to dealing with any situations after sale.

3. Test all the products before packaging.

4. Two years gurantee time.

5. We also produce all kinds of indoor and outdoor lights.

6. Free charge for samples if you are willing to pay for the shipping cost.

- Q:Patch LED beads can be bought in what place?

- Many LED packaging plants do patch LED, you can find the relevant manufacturers to contact, or go to the local electronic components market according to your needs

- Q:How can I install the patch LED lamp belt on the wood chip casting board? With double-sided glue will be hot, and can not use the clip on the screw, what should I do?

- Installed indoors, you can directly tear off the stickers on the 3M double-sided adhesive surface, and then fix the light bar where it needs to be installed. Just press it with your hands.

- Q:Patch LED light does not flash, why?

- There are three main reasons:1, the temperature is too high, resulting in LED lights, dead lights.2, do not do anti-static measures, electrostatic breakdown chip, resulting in damage to the LED light.3, the use of LED lamp quality is too bad, the purchase price reasonable LED lights

- Q:Which is good for LED patch and LED bulb?

- The LED patch is the same as the LED bulbLED (light emitting diode) patch (package)The LED patch (SMD) is made of FPC circuit board, LED and high quality silica gel sleeve. Waterproof performance, using low voltage DC power supply is safe and convenient, light colors, bright colors; outdoor use can be anti UV aging, yellowing, high temperature resistance and other advantages, the products are widely used in building lights, decorative lighting, advertising and entertainment quasi decorative lighting lighting field.LED bulbWith the LED patch or LED plug-in LED (light emitting diode), series or parallel, driving power supply, making a combined shell lampshade capable of converting electrical energy into visible solid semiconductor devices, which can be directly converted into electricity to light.

- Q:The quality of the LED patch module

- Chip size. The larger the size of the same chip, the higher the general brightness, the stronger the bearing capacity, the higher the stability performance, of course, the price is relatively high. The size of the module chips now includes: 9MIL, 10MIL, 12MIL, 14MIL, 23MIL, and so on.

- Q:SMD LED lamp working voltage?

- LED is a light emitting device of low voltage, low current, low power forward current general patch type LED when using (IF) 20MA, (VF) 1.8-2.5V, voltage of red green and blue (VF) voltage is 3.0-3.6V. Different manufacturers also have small differences, so first of all, look at the color,Of course. The multi chip assembly in high voltage chip together, some current: 1 watts, 1 watts and above. A wide variety of varieties, as follows:

- Q:LED light SMD LED package in what form, trouble you under the guidance of...

- The LED chip has bumps and is welded to the PCB board using FLIP CHIP to packaging technology.LED is English light emitting diode (light emitting diode) abbreviation, its basic structure is a electroluminescent semiconductor chip light emitting materials, with silver glue or glue curing to the bracket, connecting a chip and a circuit board and then with silver or gold, then sealed with epoxy resin around, to protect the internal core role finally, the installation shell, so the seismic performance of LED lamp is good. Field of application involves mobile phones, desk lamps, household appliances and other daily household electrical appliances and machinery production.

- Q:What determines the brightness of the patch LED?

- The brightness is consistent over a short period of time, that is, only by considering current and voltage consistency.Long term brightness is consistent with the consideration of the spacing and heat dissipation of different circuits. Uneven heat can also affect brightness.

- Q:How do led patches measure good or bad?

- The patch LED is also called SMD LED. Its principle of luminescence is to pass the current through the compound semiconductor. Through the combination of the electron and the hole, the excess energy will be released in the form of light to achieve the effect of luminescence.

- Q:Patch LED features

- The seismic resistance, high reliability, low operation cost system.It is easy to small, thin, lightweight, easy to shape without restrictions, made all kinds of application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Best Price Bridgelux Chip White 150Ma 0.5W SMD LED 5730

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords