aluminum foil with LDPE for bubble foil facing production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 cm²

- Supply Capability:

- 33412 cm²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum foil facing insulation for Roofing Insulation

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

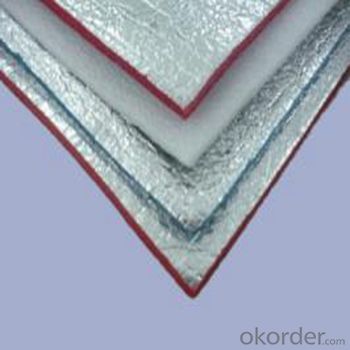

• FSK aluminum foil facing is mainly used for duct wrap in HVAC system and other fields, such as vapor barrier etc., and suitable for off-line lamination of glass wool or rock wool. By special processing, the facing will have excellent flame retardant property.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

• The PSK aluminum foil facing, whose structure is white polypropylene/ fiberglass scrim/ kraft is mainly used for metal building insulation and suitable for the insulation of ware-house, factory, supermarket, office and so on.

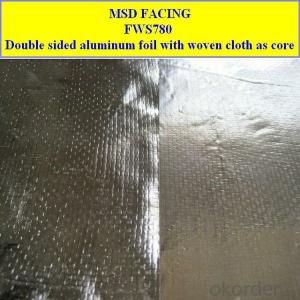

• Double sided aluminum foil facing vapor barrier, whose structure is aluminum foil/ high strength kraft /fiberglass scrim /aluminum foil and laminated together by special flame retardant adhesive, can be used for roofing, wall insulation of house, warehouse, cold storages, factory and others.

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

• Smooth and clear surface;

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

Basic weight | gsm | 120 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 140 75 | ASTM D828 |

Burst strength | N | 43 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C 66°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Basic weight | gsm | 120 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 140 75 | ASTM D828 |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

What is the storage condition?

1,The products should be stored at room temperature and kept from wet and heat source.

2, It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

3, The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q:I would like to know which direction the one side with foil faces. The roof or the interior of the room?This is an attic room. Roof being "raw" i mean that it looks like cedar tongue in groove boards...then shingles on top of them. Which way do i face the foil side of the sheet..?thanx

- Super Tuff R Insulation

- Q:Sorry, I asked this in the maintenance and repair section, but no luck.Which is better to have in a 2-story home? My last 2-story home was always hotter upstairs than down. (Physics...heat rises)

- the best is more attic isolation so that the heat don't come directly to second floor.

- Q:im thinking of putting rolled felt paper under my metal roofing would that work instead of the reflective insulation instead?

- I installed a metal roof 5 years ago. I stripped the roof down to the plywood and put down 30# felt. This was what the manufacturer recommended. The felt is not for insulation though. The company was Metal Sales out of PA. They are glad to give advise.

- Q:I live in the top most floor of a flat. Is it worth to insulate the roof (from inside) with styrofoam(thermocole) to reduce the airconditioning load. Is it really economical with respect to cost of insulation and savings gained? Any experiences?

- if u mean roof as just below the shingles this is not recommended as it will cause the shingles to become very hot and prematurely fail,,the best way to lower the heat in an attic is ventilation,,if u have an attic its best to insulate the floor of the attic and lots of ventilation

- Q:I have a valley between two roof peaks that gets a huge icicle every year. I know this area is not insulated very well. In the house it is a dead area between two rooms. I would like to get someone over here and blow it full of insulation (couple calls in, awaiting response). In the meantime, I do have heat tapes installed on the roof in this area. It's a 50' run, zigzagged and some goes into gutter and the downspout.I am paranoid of fire hazards and have a real problem leaving these tapes plugged in. That being said, I realize snow is all around and water is flowing in this case. Is it safe to leave these plugged in?Is there a time I should be unplugging?Will this help my icicle problem?Serious replies only please. I prefer from a licensed contractor/insulator.Thanks in advance.

- I have never experienced a problem with heat tape. as long as it is in good shape and you have it plugged into a GFI, I personally wouldn't worry about it to much at all. your roof gets hotter in the summer with the sun beating on it then the heat tape can create. so it starting a fire would be unlikely. the lack of insulation in that area is compounding your problem. so get that taking care of if you can. heat tape is melting snow and ice, melting snow and ice makes ice cycles. the heat tape in the gutter will help to keep the gutters clear allowing the water to flow down the spout so in theory it should not create as many ice cycles as without the tape. again the lack of insulation is allowing more snow to melt from heat loss through the roof. hope this helped, good luck

- Q:hi me and my friends made a lounge out of my old tin roof shed we have a tv speakers and a few other electrical goods... since winters on its way we were wondering whats the best and cheapest way to insulate the place note that its a tin rof but has wood under it where the old indulation used to be the place is pretty chilly and sometime damp plz help we dont wanna be freezing our asses off in there thanks :)

- I would look at using the pink insulation if it will fit between the tin roof and the under it, If not, you may have to remove the wood to install the insulation.

- Q:a roof that is built with the insulation covering the waterproof membrain is ?

- Not done properly.

- Q:I do not have extra space on the roof. Roof also tapers to drains at one end of building.

- the R values, i am not sure. that white stuff is NOT Styrofoam. it is a cheap imitation. Real Styrofoam is made by DuPont, is usually a light blue, with a plastic seal coat on both sides. that thin plastic seal coat doubles the R value. what really does the insulation, is trapped air. air is actually a poor conductor of heat. the foam is actually little bubbles of air. dead air that is, air that cannot circulate and move. it works similarly to the way a down vest or coat works, it fluffs up and holds the air pockets out within a confining structure, thus retaining heat. the rigid stuff will last much longer, i can tell you that much. the white foam stuff deteriorates quickly. buy cheap, get cheap, is the general rule. you may wind up only having to do it again in a few years.

- Q:the roof of my mouth hurts bad.i worked all day with sawdust and insulation yesterday.is this the problem.?

- it is what might have irritated your mouth. use a mask in the future. for now, increase your fluid intake and try Benedryl for a few days.

- Q:A roofer who wants to put a new roof on my mobile home says it will dry out. (We live in the rainiest part of the US)

- It shouldn't need replacement unless it is damaged someway.Like mold,dry rot or UV Damage.He should be willing to explain why and show you the condition of the roof before and after he works on it.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

aluminum foil with LDPE for bubble foil facing production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 cm²

- Supply Capability:

- 33412 cm²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords