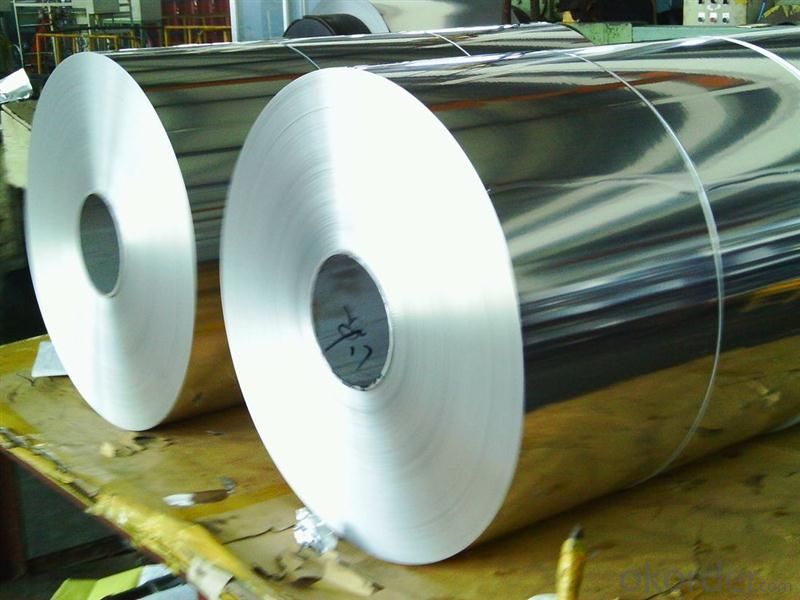

Aluminum Coil 5754 8011 1050 1060 Aluminum Coil For Cans

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Aluminum Coil 5754 8011 1050 1060 Aluminum Coil For Cans

Applications:

Aluminum foil roll is widely used in construction,decoration,hardware,

electric appliances,machinery and other industrial and civil purposes,

such as electronic capacitor,composite cooker,rice cooker,refrigerator,

computer casting,telecommunication,equipment,lamp shade,air conditioner,

cosmetics cover and so on.

Or it can be made as customers’ requirement.

Specifications

color aluminum coil

1000 series 1100 10160 1200

surface could be: Brushed, drawing, embossed, printing

color: red,

color aluminum coil

.Alloy type: 1050/1060/1100/1350

2.Temper: H16, H18, H22, H24

3.Thickness range: 0.1mm-4mm

4.Width range: 25mm-1600mm

5.Surface:finish: bright & smooth surface, without flow lines, slight oiled to avoid white rusting.

6.Quality material:totally free from such defefects as roll marks, edge damager, camber, white rust, oil patches, holes, break lines,

color aluminum coil

Name |

color aluminum coil |

Alloy or not | yes |

Alloy | 1100H16/18, 3003H24,3003H26,3005H26,8011,3004,3105,5005,etc. |

Thickness | 0.1-4mm |

Width | ≤1600mm |

MOQ | 5T |

Coating finish | Brushed, drawing, embossed, printing |

Color | As to code RAL |

Surface | Embossed,Mill Finish,Coated,Brushed |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | PVDF27 ~35micron |

Polyester18~27micron(EN ISO-2360:1995) | |

Coating hardness | 2H |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

MEK resistance | 100 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

- Q:Can aluminum coils be used in the production of aluminum ceilings?

- Yes, aluminum coils can be used in the production of aluminum ceilings. The coils are typically processed and shaped into sheets, which are then used to create the ceiling panels.

- Q:How is an aluminum coil made?

- An aluminum coil is made through a process called continuous casting and rolling. First, pure molten aluminum is poured into a continuous casting machine, which creates a solidified strip of aluminum. This strip is then fed through a series of rolling mills, where it undergoes multiple passes to achieve the desired thickness and shape. The rolling process also helps in improving the mechanical properties of the aluminum coil. Finally, the coil is coiled up and is ready to be used for various applications such as in construction, automotive, or packaging industries.

- Q:Can aluminum coils be used for structural purposes?

- Yes, aluminum coils can be used for structural purposes. Aluminum is a lightweight and versatile material that offers excellent strength-to-weight ratio. It is commonly used in various structural applications, including the construction of buildings, bridges, and aircraft. Aluminum coils can be formed and shaped into different profiles to provide support and stability in structural systems. Additionally, aluminum is highly corrosion-resistant, which makes it suitable for outdoor and marine environments. However, it is important to consider the specific requirements and load capacities of the structural project to determine if aluminum coils are suitable for the intended purpose.

- Q:Are aluminum coils suitable for high-pressure applications?

- High-pressure applications are generally not suitable for aluminum coils due to their low strength compared to metals like steel or copper. Despite being lightweight and corrosion-resistant, aluminum coils are prone to deformation or failure under high pressure. In order to withstand significant stress and ensure a robust system, materials with higher strength such as copper or stainless steel are commonly used in such applications. Nevertheless, it is crucial to refer to industry standards, guidelines, and specific requirements to determine the most suitable material for a particular high-pressure application.

- Q:How does the gauge of aluminum coils affect their performance?

- The thickness of the aluminum sheet used to make the coil determines the gauge of aluminum coils. The gauge is typically measured by its thickness, with a smaller gauge indicating a thicker sheet. The performance of aluminum coils is significantly influenced by their gauge. To begin with, the strength and durability of the aluminum coil are affected by the gauge. Thicker gauges offer greater strength and resistance to bending or warping, making them suitable for applications that require sturdy and long-lasting coils. Conversely, thinner gauges are more flexible but may be prone to damage or deformation, making them suitable for less demanding applications. Furthermore, the gauge affects the thermal conductivity of the aluminum coil. Thicker gauges have lower thermal conductivity, resulting in slower heating or cooling. This characteristic can be advantageous in applications where precise temperature control is crucial, as it helps maintain a stable environment. On the other hand, thinner gauges have higher thermal conductivity, enabling faster heat transfer. This can be beneficial in applications that require rapid heating or cooling. Moreover, the gauge affects the weight and cost of the aluminum coil. Thicker gauges are heavier and generally more expensive due to the increased amount of material required. This factor is important to consider in applications where weight or cost plays a significant role. Thinner gauges, being lighter and less expensive, are more suitable for applications that prioritize weight reduction or cost efficiency. Lastly, the gauge influences the ease of fabrication and formability of the aluminum coil. Thinner gauges are more easily bent, shaped, or formed into desired configurations, making them suitable for applications that involve intricate or complex designs. Although thicker gauges are less malleable, they can still be formed with specialized equipment or processes. In conclusion, the gauge of aluminum coils directly affects their performance. It influences their strength, durability, thermal conductivity, weight, cost, and formability. Therefore, selecting the appropriate gauge for a specific application is crucial to ensure optimal performance and efficiency.

- Q:Can aluminum coils be used in heat exchangers?

- Indeed, heat exchangers can utilize aluminum coils. The utilization of aluminum in heat exchangers is prevalent owing to its exceptional thermal conductivity and resistance to corrosion. Aluminum's remarkable thermal conductivity enables efficient heat transfer, rendering it an optimal substance for heat exchangers. Furthermore, the coils' endurance and functionality in challenging surroundings are guaranteed by aluminum's resistance to corrosion.

- Q:Can aluminum coils be used in food processing equipment?

- Indeed, food processing equipment can utilize aluminum coils. The numerous advantageous properties of aluminum make it a favored option for food-related applications. Its lightweight nature, resistance to corrosion, and exceptional thermal conductivity render aluminum coils appropriate for deployment in refrigerators, freezers, ovens, and heat exchangers within the realm of food processing equipment. Furthermore, aluminum is non-toxic and does not interact with food, thereby establishing it as a secure material for direct interaction with consumable items. Nevertheless, it remains crucial to verify that the aluminum employed in food processing equipment adheres to the requisite food safety standards and regulations, thereby averting any potential contamination.

- Q:im taking avelox antibiotic for my thorat bacterial infection....i brought guava juice today but i think it contains magnesium or aluminum....how long after taking avelox can i drink the guava juice????

- Avelox has a drug interaction with aluminum hydroxide, aluminum-magnesium hydroxide, calcium carbonate, didanosine, magnesium hydroxide, multivitamins and things that contain zinc. The specific interaction is that these may interfere with the absorption of moxifloxacin (Avelox) in your G.I. tract . Either take the Avelox either 4 hours before or take it 8 hours after ingesting these. Or do it the other way around - eat/drink things on this list 4 hours after taking the Avelox or 8 hours before taking Avelox. If you find this to be too much work, avoid all products on this list until the Avelox protocol is completed. Guavas have magnesium.

- Q:Can aluminum coils be used in high-temperature applications?

- No, aluminum coils are not suitable for high-temperature applications as they have a low melting point and tend to lose their structural integrity at elevated temperatures.

- Q:Can aluminum coils be used in high-pressure or high-temperature environments?

- Aluminum coils are not typically recommended for use in high-pressure or high-temperature environments. While aluminum is known for its high thermal conductivity and corrosion resistance, it has certain limitations when exposed to extreme conditions. In terms of high-pressure environments, aluminum coils may not possess the necessary strength and durability required to withstand the forces exerted by the pressurized system. Aluminum has a lower tensile strength compared to other metals like steel or titanium, which makes it more prone to deformation or failure under high pressure. Therefore, it is generally advised to use materials with higher strength and pressure ratings in such scenarios. Similarly, aluminum coils have a relatively low melting point compared to metals like steel or copper. The melting point of aluminum is around 660 degrees Celsius (1220 degrees Fahrenheit), which makes it susceptible to damage or failure in high-temperature environments. In applications where the temperature exceeds the melting point of aluminum, it is recommended to use materials with higher temperature resistance. However, it is worth mentioning that there are specialized alloys and coatings available that can enhance the high-temperature and high-pressure capabilities of aluminum. These modifications can improve its strength, heat resistance, and corrosion resistance, making it suitable for certain applications in extreme conditions. Nonetheless, the specific requirements and limitations of the intended environment should be carefully considered before deciding to use aluminum coils. Consulting with experts and considering alternative materials may be necessary to ensure the safety and efficiency of the system.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Coil 5754 8011 1050 1060 Aluminum Coil For Cans

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords