Aluminum Coated Strips Used for Ring-Pull 5182 H48

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Coated Strips Used for Ring-Pull 5182 H48

We professionally produce aluminium coated strips used for can tabs or ring-pulls. During production, we use large wave shear, transverse shear and longitudinal cut system so as to meet different specifications of customers.

Based on ordinary aluminum, we add Mn and Mg, so as to increase tensile strength and elongation. Normally we use 5182, H48 for production.

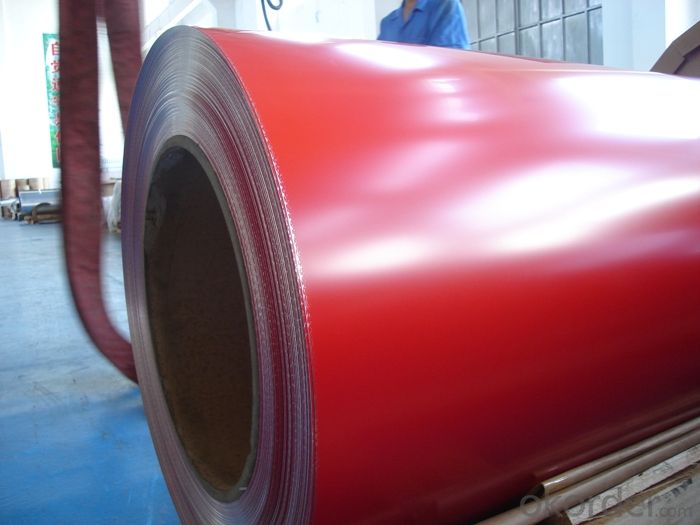

Our coated aluminum strips for tabs are colorful and glossy. We have different colors for tabs, such as blue, red, transparent, etc. We also can adjust coating according to color of customers and offer personalized services.

2. Main Features of Aluminum Coated Strips Used for Ring-Pull 5182 H48

• Light Weight

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rustproof

3. Aluminum Coated Strips Used for Ring-Pull 5182 H48 Images

4. Specification of Aluminum Coated Strips Used for Ring-Pull 5182 H48

ALLOY | TEMPER | THICKNESS | WIDTH | COIL OR LENGTH |

5052 5182 | H19 H36 H48 H49 | 0.22-0.5mm | 500-1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q:What is the typical thickness of aluminum coils?

- The intended use and application of aluminum coils can result in varying thicknesses. Generally, a range of thicknesses is accessible, spanning from 0.006 inches (0.15 mm) to 0.25 inches (6.35 mm). The specific thickness needed for a specific project or industry hinges on factors like desired strength, flexibility, and weight of the aluminum coils.

- Q:just wondering if you can weld aluminum pipe to a metal pipe for a cars exuast

- i don't see why not becasue volvo uses aluminum exhaust systems.

- Q:Can aluminum coils be used in the production of aluminum honeycomb panels?

- Aluminum honeycomb panels can indeed incorporate aluminum coils in their production process. To create these panels, aluminum sheets are affixed to a honeycomb core material, typically composed of aluminum as well. The aluminum coils are commonly employed to manufacture the aluminum sheets forming the panels' outer layer. After being rolled into thin sheets, these coils are cut to the desired dimensions and subsequently bonded to the honeycomb core. The utilization of aluminum coils enables the efficient and cost-effective manufacture of aluminum honeycomb panels, as they can be easily molded and processed to meet the necessary shape and size requirements. Moreover, aluminum possesses the qualities of being lightweight and durable, rendering it an optimal selection for fabricating honeycomb panels utilized in diverse industries, including aerospace, construction, and transportation.

- Q:How are aluminum coils joined or welded?

- Aluminum coils can undergo various methods of joining or welding, depending on the specific application and desired outcome. Some commonly employed techniques are: 1. Mechanical fastening: This involves physically fastening the aluminum coils together using bolts, screws, or rivets. Mechanical fastening is a cost-effective and straightforward method suitable for thin coils or temporary connections. 2. Adhesive bonding: Specialized adhesives are used to bond aluminum coils together in adhesive bonding. This method creates a strong and durable joint, evenly distributing stress across the entire bond area. Adhesive bonding is often used when aesthetics, weight reduction, or vibration dampening are important considerations. 3. Resistance welding: Resistance welding employs an electric current to generate heat and pressure at the joint, effectively welding the aluminum coils. This method is particularly suitable for high-speed production lines, providing a strong and reliable joint. However, it requires specialized equipment and may not be suitable for all aluminum alloys. 4. Laser welding: Laser welding is a precise and efficient method that utilizes a laser beam to melt and join the aluminum coils. This technique allows for precise control of heat input, resulting in minimal distortion and excellent weld quality. Laser welding is commonly used in industries where high precision and aesthetic appearance are crucial, such as automotive and aerospace. 5. Friction stir welding: Friction stir welding is a solid-state joining process that employs a rotating tool to generate heat and friction, effectively welding the aluminum coils without melting the material. This method produces strong and high-quality welds with minimal distortion and no need for additional filler material. Friction stir welding is commonly used in industries that require excellent mechanical properties and high productivity, such as shipbuilding and railway construction. Overall, the choice of joining or welding method for aluminum coils depends on factors such as desired joint strength, application requirements, production volume, and available equipment and expertise.

- Q:Can aluminum coils be coated with protective films?

- Coating aluminum coils with protective films is a prevalent practice across industries. These films, typically composed of materials like polyester or polyethylene, are applied to the coils using adhesive or heat bonding. Their main purpose is to safeguard the coils from damage, scratches, or corrosion during storage, transportation, or processing. Acting as a barrier, the films shield the coils from moisture, dirt, chemicals, and other external factors. Some protective films even offer temporary UV protection. Ultimately, this practice guarantees the preservation of the coils' quality and integrity throughout their handling and usage.

- Q:I need to lay down two 3 welds on some 1/8 aluminum but my welder is not set up for it. could i just out fit my welder with aluminum wire without buying the spool gun and get the same results? or maybe I should just get a welding shop to do it for me?

- What is your machine that you will be using? Can you weld AC on it? Do you have a High Freq. Box? Will you GTAW it or use GMAW? What Alloy of Aluminum is it? Need much more info than you have provided. If GMAW best to have a pull or a push / pull wire feed system such as in a spool gun. Aluminum is too soft to just push from a wire feeder unit.

- Q:How are aluminum coils processed to achieve desired mechanical properties?

- Aluminum coils are processed to achieve desired mechanical properties through a combination of cold rolling, annealing, and heat treatment. Cold rolling reduces the thickness of the aluminum coil, increasing its strength and hardness. Annealing, a heat treatment process, is then applied to soften the material and improve its formability. Additional heat treatments may be conducted to further enhance mechanical properties, such as tempering to increase toughness or solution heat treatment to improve strength and corrosion resistance. These processing techniques allow manufacturers to tailor the mechanical properties of aluminum coils to meet specific application requirements.

- Q:Can aluminum coils be used for heat sinks?

- Yes, aluminum coils can be used for heat sinks. Aluminum is a popular choice for heat sinks due to its excellent thermal conductivity properties. Heat sinks are designed to dissipate heat generated by electronic components, such as processors or power transistors, to prevent overheating and ensure optimal performance. Aluminum coils can effectively transfer heat away from the heat source and distribute it over a larger surface area, allowing for efficient heat dissipation. Additionally, aluminum is lightweight, corrosion-resistant, and cost-effective, making it a suitable material for heat sink applications.

- Q:What are the different thickness tolerances for aluminum coils?

- The specific grade and application of aluminum coils can cause variations in their thickness tolerances. Generally, the standard range for these tolerances is typically between +/- 0.002 and 0.015 inches. Consequently, the actual thickness of the aluminum coil can differ within these limits. The specific tolerance requirements may also be affected by factors like the manufacturing process and the intended use of the coil. Therefore, it is crucial to refer to industry standards and specifications to ascertain the necessary thickness tolerances for a specific application.

- Q:How are aluminum coils used in the manufacturing of cookware?

- Due to their exceptional heat conductivity and lightweight nature, aluminum coils find extensive use in the production of cookware. Cookware manufacturers typically rely on aluminum coils as the primary material for constructing the bases and bodies of pots, pans, and other cooking utensils. To begin with, the process involves rolling out the aluminum coils and subsequently cutting them into various shapes and sizes to match the desired cookware product. Preferred over alternative materials such as stainless steel or cast iron, these coils excel in heat conduction, ensuring even distribution of heat across the cookware's surface for thorough and uniform cooking. Furthermore, the lightweight nature of aluminum coils enhances the manageability and maneuverability of the resulting cookware. This is particularly advantageous for professional chefs and home cooks, who frequently need to lift and move pots and pans while cooking. Moreover, due to the malleability of aluminum, it can be easily shaped and molded into diverse designs and styles for different cookware types like saucepans, frying pans, or baking trays. This versatility in cookware manufacturing allows for customization according to specific needs. Additionally, aluminum exhibits natural resistance to corrosion, making it a durable option for cookware. It remains unaffected by acidic or alkaline ingredients commonly used in cooking, ensuring the cookware's safety for food preparation and cooking. Lastly, aluminum coils can undergo treatments with non-stick coatings like Teflon, introducing the benefits of non-stick cookware. These coatings provide added convenience by facilitating easy food release and hassle-free cleaning. In conclusion, the utilization of aluminum coils in cookware manufacturing is essential due to their exceptional heat conductivity, lightweight construction, versatility in design, durability, and the option for non-stick coatings. These qualities make aluminum coils the ideal choice for producing high-quality cookware that delivers superior cooking performance and convenience in the kitchen.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Coated Strips Used for Ring-Pull 5182 H48

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords