All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

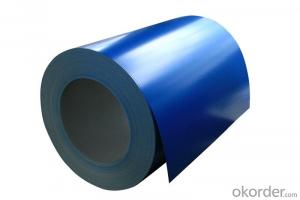

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the impact of alloy selection on the formability of aluminum coils?

The impact of alloy selection on the formability of aluminum coils is significant. Different aluminum alloys have varying mechanical properties, such as strength, ductility, and hardness, which directly affect their formability. Alloys with higher ductility are more easily deformed and shaped, making them suitable for applications requiring complex and intricate forms. Conversely, alloys with higher strength but lower ductility may be more difficult to form. Therefore, selecting the appropriate aluminum alloy for coil manufacturing is crucial to ensure optimal formability and achieve desired shapes and designs.

What is the role of aluminum coils in the manufacturing of aluminum enclosures for electronics?

The role of aluminum coils in the manufacturing of aluminum enclosures for electronics is to provide the raw material necessary for shaping and forming the enclosure. The coils are typically rolled into thin sheets which can then be cut, bent, and molded into the desired shape for the enclosure. These sheets offer excellent strength, durability, and corrosion resistance, making them ideal for protecting and housing electronic components.

How are aluminum coils used in the production of aluminum foil?

Aluminum coils are used in the production of aluminum foil by being heated and then rolled to reduce their thickness. This process, known as cold rolling, allows the aluminum to be transformed into thin sheets, which are then further processed and annealed to enhance their strength and flexibility. The coils serve as the starting material, providing a continuous supply of aluminum to create the thin layers that form aluminum foil.

What is the maximum length of aluminum coils available?

The maximum length of aluminum coils available varies depending on the supplier and specific requirements, but it can typically range from a few hundred feet to several thousand feet.

Wholesale Aluminum Coils from supplier in Botswana

By choosing us, you can benefit from our strong network and relationships with manufacturers, allowing us to provide competitive pricing and fast delivery. We understand the importance of timely delivery and strive to meet your project deadlines.

Furthermore, we offer a range of value-added services, including customized cutting and packaging options, to ensure that the Aluminum Coils meet your specific requirements. Our team of experts is always available to provide technical support, answer any questions, and address any concerns you may have.

In addition to our commitment to quality and customer satisfaction, we also prioritize sustainability. We strive to minimize our environmental impact by promoting the use of recycled materials and implementing eco-friendly practices throughout our operations.

At our core, we are dedicated to building long-term partnerships with our clients. We aim to be your go-to supplier for Aluminum Coils in Botswana, providing reliable and efficient solutions for your business needs. Trust us to deliver exceptional products and services that drive your success.

Contact us today to discuss your Aluminum Coils requirements and experience the difference of working with a leading supplier in Botswana.

Furthermore, we offer a range of value-added services, including customized cutting and packaging options, to ensure that the Aluminum Coils meet your specific requirements. Our team of experts is always available to provide technical support, answer any questions, and address any concerns you may have.

In addition to our commitment to quality and customer satisfaction, we also prioritize sustainability. We strive to minimize our environmental impact by promoting the use of recycled materials and implementing eco-friendly practices throughout our operations.

At our core, we are dedicated to building long-term partnerships with our clients. We aim to be your go-to supplier for Aluminum Coils in Botswana, providing reliable and efficient solutions for your business needs. Trust us to deliver exceptional products and services that drive your success.

Contact us today to discuss your Aluminum Coils requirements and experience the difference of working with a leading supplier in Botswana.