All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the environmental benefits of using recycled aluminum in profile manufacturing?

Using recycled aluminum in profile manufacturing offers several environmental benefits. Firstly, it helps conserve natural resources as recycling aluminum requires significantly less energy and resources compared to mining and extracting new aluminum. This reduces the need for destructive mining practices, which can harm ecosystems and contribute to deforestation.

Additionally, recycling aluminum reduces greenhouse gas emissions. The production of new aluminum from raw materials releases a significant amount of carbon dioxide, whereas recycling aluminum results in much lower emissions. This helps mitigate climate change and reduce air pollution.

Moreover, recycling aluminum reduces landfill waste. Aluminum is a highly recyclable material, and by reusing it in profile manufacturing, we can divert it from landfills where it would take hundreds of years to decompose. This reduces the strain on landfills and helps to minimize the release of harmful substances into the environment.

Overall, using recycled aluminum in profile manufacturing promotes sustainability, reduces resource consumption, minimizes greenhouse gas emissions, and decreases waste, making it a more environmentally friendly choice.

How are aluminum profiles used in the development of cutting-edge automotive technologies and components?

Aluminum profiles are extensively used in the development of cutting-edge automotive technologies and components due to their exceptional properties such as lightweight, high strength, and excellent corrosion resistance. These profiles are commonly utilized in the manufacturing of lightweight vehicle structures, chassis, body panels, and various other components. The use of aluminum profiles enables car manufacturers to reduce the overall weight of vehicles, leading to improved fuel efficiency, enhanced performance, and reduced emissions. Additionally, these profiles offer design flexibility, allowing for the creation of complex shapes and forms that contribute to innovative automotive designs.

How do you calculate the weight-bearing capacity of an aluminum profile?

To calculate the weight-bearing capacity of an aluminum profile, you need to consider various factors such as the dimensions of the profile, the material properties of the aluminum, and the structural design. It involves analyzing the profile's cross-sectional area, moment of inertia, and the load it is expected to bear. These calculations can be performed using engineering principles and mathematical formulas to determine the maximum weight the aluminum profile can safely support without failure.

Wholesale Aluminum Profiles from supplier in Australia

With our wide range of Aluminum Profiles products, we are committed to providing comprehensive solutions to meet all your needs. Whether you require standard profiles or customized options, we have the expertise to assist you. Our sales team is dedicated to understanding your requirements and providing accurate and competitive quotes. We also offer technical support to ensure that you have all the information and guidance you need for your project.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the resources and capabilities to meet your procurement needs. CNBM is a trusted name in the industry, known for its high-quality products and excellent customer service. With our strong backing, you can trust us to deliver reliable and superior Aluminum Profiles solutions.

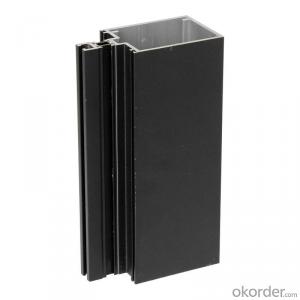

Our extensive product portfolio includes a wide range of profiles, such as extruded profiles, heat sink profiles, curtain wall profiles, and more. We offer diverse options in terms of material, finish, and dimensions to suit your specific requirements. Whether you are involved in construction, manufacturing, or any other industry, we have the right Aluminum Profiles for you.

With years of experience in the Australian market, we understand the unique challenges and requirements of local projects. Our team has in-depth knowledge of local regulations and standards, ensuring that our solutions comply with all necessary requirements. We also stay updated with the latest industry trends and innovations, allowing us to provide valuable insights and recommendations for your project.

By choosing our one-stop Aluminum Profiles solutions, you can enjoy the convenience of a streamlined procurement process. We handle everything from sales to delivery, ensuring a hassle-free experience for our customers. Our commitment to customer satisfaction means that we go above and beyond to meet your expectations.

Experience the convenience, reliability, and expertise of our Aluminum Profiles solutions in Australia. Contact us today to discuss your requirements and discover how we can assist you in achieving your project goals.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the resources and capabilities to meet your procurement needs. CNBM is a trusted name in the industry, known for its high-quality products and excellent customer service. With our strong backing, you can trust us to deliver reliable and superior Aluminum Profiles solutions.

Our extensive product portfolio includes a wide range of profiles, such as extruded profiles, heat sink profiles, curtain wall profiles, and more. We offer diverse options in terms of material, finish, and dimensions to suit your specific requirements. Whether you are involved in construction, manufacturing, or any other industry, we have the right Aluminum Profiles for you.

With years of experience in the Australian market, we understand the unique challenges and requirements of local projects. Our team has in-depth knowledge of local regulations and standards, ensuring that our solutions comply with all necessary requirements. We also stay updated with the latest industry trends and innovations, allowing us to provide valuable insights and recommendations for your project.

By choosing our one-stop Aluminum Profiles solutions, you can enjoy the convenience of a streamlined procurement process. We handle everything from sales to delivery, ensuring a hassle-free experience for our customers. Our commitment to customer satisfaction means that we go above and beyond to meet your expectations.

Experience the convenience, reliability, and expertise of our Aluminum Profiles solutions in Australia. Contact us today to discuss your requirements and discover how we can assist you in achieving your project goals.