All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

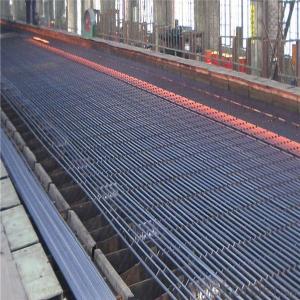

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the impact of seismic retrofitting using steel rebars in earthquake-prone regions?

Seismic retrofitting using steel rebars in earthquake-prone regions has a significant impact on enhancing the structural integrity and resilience of buildings. These rebars, which are embedded within concrete, strengthen the structure by increasing its load-bearing capacity and ability to withstand seismic forces. By preventing or minimizing structural damage during earthquakes, steel rebars contribute to saving lives and reducing economic losses. Additionally, retrofitting existing buildings with steel rebars is often more cost-effective than demolishing and rebuilding, making it a practical and sustainable solution for improving the safety of infrastructure in earthquake-prone regions.

What are the considerations for using stainless steel rebars in aggressive coastal regions prone to saltwater exposure?

Stainless steel rebars are an excellent choice for aggressive coastal regions prone to saltwater exposure due to their exceptional corrosion resistance. However, there are a few considerations to keep in mind. Firstly, the grade of stainless steel should be carefully selected based on the specific environment and chloride concentration. Additionally, proper installation techniques and maintenance procedures must be followed to ensure the longevity and effectiveness of stainless steel rebars in saltwater environments. Regular inspection and cleaning are also crucial to prevent any potential buildup of contaminants or corrosion.

How do you ensure the proper lap length for steel rebars in the reinforcement of concrete walls?

To ensure the proper lap length for steel rebars in the reinforcement of concrete walls, a few steps can be followed. First, it is important to refer to the design specifications and guidelines provided by relevant engineering codes and standards. These specifications will outline the required lap length based on factors such as the rebar diameter, concrete strength, and the structural requirements of the wall.

Next, during construction, it is crucial to use proper reinforcement detailing and placement techniques. This includes accurately positioning the rebars at the specified locations and maintaining the required spacing between them. Adequate cover should also be provided to protect the rebars from corrosion and ensure the durability of the structure.

In addition, regular inspections and quality control checks should be carried out during the construction process. This involves verifying the correct lap length by measuring the overlap between adjacent rebars and ensuring it meets the required criteria. Any deviations or discrepancies should be promptly addressed and corrected to maintain the integrity of the reinforcement.

Overall, a combination of careful planning, adherence to design specifications, proper construction techniques, and diligent quality control measures are essential in ensuring the proper lap length for steel rebars in the reinforcement of concrete walls.

Wholesale Steel Rebars from supplier in Australia

Our team of experts is dedicated to providing exceptional customer service and ensuring that your experience with us is smooth and hassle-free. We understand the importance of timely delivery and strive to meet your deadlines without compromising on quality.

In addition to our wide product portfolio, we also offer customization options to meet your unique specifications. Our technical support team is available to answer any questions you may have and provide guidance on the best Steel Rebars products for your specific project.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and resources, enabling us to offer competitive prices without compromising on quality. We are committed to building long-term relationships with our customers and aim to be your go-to supplier for all your Steel Rebars needs in Australia.

Contact us today for a quote or to discuss your requirements. We look forward to partnering with you and providing you with the highest quality Steel Rebars products and exceptional service.

In addition to our wide product portfolio, we also offer customization options to meet your unique specifications. Our technical support team is available to answer any questions you may have and provide guidance on the best Steel Rebars products for your specific project.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and resources, enabling us to offer competitive prices without compromising on quality. We are committed to building long-term relationships with our customers and aim to be your go-to supplier for all your Steel Rebars needs in Australia.

Contact us today for a quote or to discuss your requirements. We look forward to partnering with you and providing you with the highest quality Steel Rebars products and exceptional service.