Aluminium Composite Panel ACP Sheet with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Aluminium Composite Panel ACP Sheet Description:

The substrates of composite materials are sheets, strips and foils of aluminum alloy. The raw material is aluminum sheet, strip, and foil. One side compund 50-200um special polymer materials, such as Polysurlyn; the other side is coated with 5-15um epoxy or polyester or fluorocarbon coatings. The back side coating is always the protective paint, and the obverse side can compound another PE protective coating.It's non-Heat treatable aluminum alloy with good corrosion resistance, good machinability, good electric arc welding performance,beautiful surface after anodic treatment.Commonly used in aviation,shipping field,also extensive used in the conventional industry,such as cars,planes,welding pieces,Metro and light rail,need strict fireproof pressure vessel,such as liquid tankers,refrigerated trucks, refrigerated container,refrigeration equipment,television tower,drilling equipment,transportation equipment,missile parts,armor,etc.

2.Main Features of Aluminium Composite Panel ACP Sheet :

Good Corrosion Resistance

Good Machinability

High Quality

Competitive Price

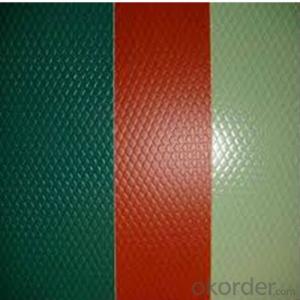

3. Aluminium Composite Panel ACP Sheet Images:

4. Aluminium Composite Panel ACP Sheet Specification:

Product Name | Thickness | Width(mm) | Length(mm) | Application |

Aluminium Coil | 0.1-6.0mm | 15-1500 | - | Aerospace, mould, instruments and meters, chemical industry, construction, packaging, anti-corrosion,insulation, air conditioning and other industries. |

Aluminium Sheet | 0.1-6.0mm | 100-2000 | 100-6000 | Solar energy, refrigerators, transport, electronics, electrical appliances, curtain wall, logos, signs and other industries. |

Aluminium Checkered Sheet | 0.3-3.0mm | Max.1200 | customized | Solar energy, water heaters, refrigerators, freezers |

Aluminium Corrugated Sheet | 0.3-3.0mm | 820-1067 | customized | Thermal power plants, chemical plants such as anti-corrosion,insulation |

Cable Foil/Coil | 0.2-0.7mm | 15-1500 | - | Wire and cable manufacturing industry |

Insulation Aluminium Coil | 0.5-3.0mm | 15-1500 | - | Desulfurization, car outside cover, wall body and roof cover. |

Air Conditioner Foil | 0.08-0.20mm | 15-1500 | - | Air conditioners, refrigerators, freezers and other radiator fin stock. |

Hydrophilic Foil | 0.08-0.20mm | 15-1000 | - | Air conditioners, refrigerators, freezers and other radiator fin stock. |

PS Sheet (aluminium Coil) | 0.3-1.0mm | 15-1500 | - | Graphic Arts |

Curtain Wall Panel (Aluminium Sheet) | 0.6-3.0mm | 100-2000 | 100-6000 | Building decoration, construction decoration |

Non-slip Aluminium Sheet | 1.0-6.0mm | Max.1200 | customized | Cars, ships, machinery and others devices. |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q:How are aluminum coils processed for specific applications?

- Aluminum coils undergo a series of processes to tailor them for specific applications. The first step is the selection of high-quality aluminum alloy, which determines the coil's properties. Once the alloy is chosen, it is melted and cast into large ingots. After cooling, the ingots are rolled between heavy rollers to reduce their thickness and form long, continuous aluminum coils. Next, the coils are subjected to various surface treatments to enhance their performance and appearance. One common treatment is cleaning, which removes any impurities or contaminants from the coil's surface. This is typically done through chemical or mechanical methods. Another treatment is chemically etching the surface to create a specific texture or pattern, which can improve adhesion or aesthetics. To further enhance the coil's properties, it may undergo processes like heat treatment or annealing. Heat treatment involves heating the coil to a specific temperature and then rapidly cooling it to modify its mechanical or physical properties. Annealing, on the other hand, involves heating the coil to a predetermined temperature and then slowly cooling it to relieve internal stresses and improve its ductility. Coils destined for specific applications may also undergo additional processes. For instance, if the coil is intended for use in the automotive industry, it may be subjected to lubrication or coating processes to reduce friction or improve corrosion resistance. If it is meant for electrical applications, it might undergo surface treatments to enhance its conductivity or insulation properties. Finally, the coils are usually cut into desired lengths and packaged for transportation. This can be done through various methods like slitting, shearing, or sawing, depending on the application and customer requirements. Overall, the processing of aluminum coils for specific applications involves a combination of casting, rolling, surface treatment, heat treatment, and additional processes to enhance their performance, appearance, and suitability for their intended use.

- Q:Are aluminum coils prone to corrosion?

- Yes, aluminum coils are prone to corrosion. Aluminum is a reactive metal that easily forms a protective oxide layer when exposed to oxygen. However, this oxide layer can be compromised by certain environmental factors, such as exposure to moisture, salt, or other corrosive substances. Over time, this can lead to the formation of corrosion on the surface of aluminum coils. Regular maintenance and proper care, such as cleaning and applying protective coatings, can help mitigate the risk of corrosion.

- Q:Are there any restrictions on the coil thickness of aluminum coils?

- Yes, there are typically restrictions on the coil thickness of aluminum coils. The specific restrictions may vary depending on the intended application and industry standards. Generally, the thickness of aluminum coils is limited by the capabilities of the manufacturing equipment and the desired final product. Thinner coils are often preferred for applications that require flexibility, such as in the manufacturing of foils or flexible packaging materials. On the other hand, thicker coils are commonly used in industries like construction or automotive, where strength and durability are important factors. Additionally, the thickness of aluminum coils may be restricted by the availability and cost of raw materials. It is important for manufacturers to adhere to these restrictions to ensure the quality and performance of the final product.

- Q:What are the different alloy grades used in aluminum coils?

- There are several different alloy grades used in aluminum coils, each with their own unique properties and applications. Some of the most commonly used alloy grades include: 1. 1100: This is a commercially pure aluminum grade, known for its excellent corrosion resistance and high thermal conductivity. It is often used in applications that require good formability, such as fin stock, heat exchangers, and chemical equipment. 2. 3003: This alloy grade is known for its moderate strength and good workability. It is commonly used in applications that require both corrosion resistance and formability, such as packaging, cooking utensils, and general sheet metal work. 3. 5052: This alloy grade offers a good combination of strength, formability, and corrosion resistance. It is often used in marine environments, as well as in transportation equipment, such as fuel tanks and vehicle bodies. 4. 6061: This is a heat-treatable alloy grade, known for its excellent strength and weldability. It is commonly used in structural applications, such as bridges, aircraft parts, and bicycle frames. 5. 7075: This is another heat-treatable alloy grade, known for its high strength-to-weight ratio. It is often used in aerospace applications, as well as in the manufacturing of high-stress components, such as firearm parts and rock climbing equipment. These are just a few examples of the different alloy grades used in aluminum coils. The selection of the appropriate grade depends on the specific requirements of the application, such as desired strength, corrosion resistance, formability, and thermal conductivity.

- Q:Are aluminum coils suitable for high-pressure applications?

- High-pressure applications are generally not suitable for aluminum coils due to their low strength compared to metals like steel or copper. Despite being lightweight and corrosion-resistant, aluminum coils are prone to deformation or failure under high pressure. In order to withstand significant stress and ensure a robust system, materials with higher strength such as copper or stainless steel are commonly used in such applications. Nevertheless, it is crucial to refer to industry standards, guidelines, and specific requirements to determine the most suitable material for a particular high-pressure application.

- Q:How can aluminium ingots be processed into aluminium coils (aluminium sheets)?

- This depends on what kind of ingot, and if it is small, it needs to be melted into a furnace, cast into a large plate, and then rolled on a mill

- Q:What is the typical elongation of aluminum coils?

- The elongation of aluminum coils can vary depending on various factors, including the specific alloy and temper of the aluminum, the manufacturing process, and the intended application. However, aluminum coils generally have a high capacity for elongation. On an average basis, aluminum coils can stretch or deform by approximately 5-15% without fracturing or breaking. This is possible due to the inherent ductility of aluminum, which enables it to be easily shaped and formed without compromising its structural integrity. The elongation of aluminum coils plays a significant role in multiple industries, such as construction, automotive, and aerospace, where the material is commonly utilized. This characteristic allows for efficient fabrication procedures, including bending, rolling, and stamping, to create intricate and precise shapes. It is important to highlight that the elongation of aluminum coils can be further enhanced through the incorporation of specific alloying elements and heat treatments. These processes can improve the material's properties, making it even more suitable for demanding applications that require exceptional strength, ductility, and elongation capabilities. To accurately determine the elongation properties for a specific application, it is crucial to consider the particular alloy, temper, and manufacturing processes involved. In conclusion, while the typical elongation of aluminum coils ranges from 5-15%, a comprehensive evaluation of these factors is necessary.

- Q:How do aluminum coils contribute to the sound insulation of buildings?

- Aluminum coils contribute to the sound insulation of buildings through their unique properties and applications. Aluminum is a lightweight and flexible material that can be easily formed into coils, making it an ideal choice for sound insulation purposes. One of the main ways aluminum coils contribute to sound insulation is by acting as a barrier to prevent the transmission of sound waves. When installed in walls, ceilings, or floors, these coils create an additional layer that helps to block and absorb sound energy. Aluminum has a high density and rigidity, which allows it to effectively reflect and absorb sound waves, reducing their intensity as they pass through the building structure. Moreover, aluminum coils can be combined with other soundproofing materials, such as foam or fiberglass, to enhance their sound absorption capabilities. These combinations provide a more comprehensive sound insulation system, as the different materials work together to trap and dampen sound waves. Another advantage of aluminum coils is their resistance to moisture and corrosion, which makes them suitable for both indoor and outdoor applications. This durability ensures that the sound insulation provided by aluminum coils remains effective over time, even in harsh environments. Additionally, aluminum coils are easy to install and maintain, making them a cost-effective solution for sound insulation in buildings. Their lightweight nature allows for easy transportation and handling, while their flexibility enables them to be installed in various positions and configurations. In summary, aluminum coils contribute to the sound insulation of buildings by acting as a barrier to sound transmission, reflecting and absorbing sound waves, and providing durability and versatility. Their combination with other soundproofing materials further enhances their effectiveness. With their lightweight and flexible properties, aluminum coils offer a practical and cost-effective solution to improve the acoustic performance of buildings.

- Q:Can aluminum coils be used in electrical transmission systems?

- Aluminum coils have the ability to be utilized in electrical transmission systems. The utilization of aluminum is prevalent in electrical transmission systems due to its advantageous electrical conductivity, high strength-to-weight ratio, and cost-effectiveness in comparison to other materials like copper. Transformers, motors, generators, and other electrical devices benefit from the application of aluminum coils. Additionally, aluminum coils possess the advantage of being lightweight, simplifying their handling and installation in transmission systems. It is important, however, to take into account that aluminum has lower electrical conductivity than copper, necessitating larger cross-sectional areas to achieve the same electrical performance. To maintain efficiency, reliability, and safety, it is crucial to adhere to proper design and engineering practices when sizing and connecting aluminum coils in electrical transmission systems.

- Q:I am concerned about the environment so I collect empty aluminum cans off the street when I walk my dog. Right now I have 3 large garbage bags full of crushed aluminum can. The problem is... some of the cans have dirt on and in them. Some of thoroughly flattened ones may even have small pebbles embedded in them. Will these be accepted at the recycling facility? I'm guessing it doesn't matter because when they melt them any organic materials will burn away and any dirt particles or small pebbles will be separated from the molten aluminum. What do you think?

- yes they won't care about dirt

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Composite Panel ACP Sheet with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords