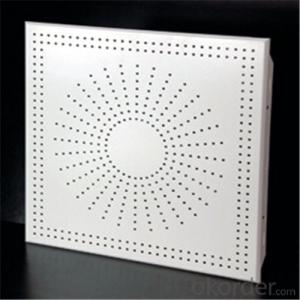

Aluminium Ceiling Clip In Type Perforated Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Our square ceiling series include:plan square ceilings,down-level ceilings,combination ceilings,perforated ceilings.

Application

Our aluminum square ceilingcan be widely applied for office,shopping mall,conference room,laboratory and exhibition hall.

Features

1.Rgulated shape

2.Beauty

3.Elegance

4.Widen vision

5.Easy installation

6.Easy cleaning

Square Ceiling series

1.plain square ceiling

2.down-level ceiling

3.combination ceiling

4.perforated ceiling

Base material

Aluminum alloy ,the gread of aluminum alloy can be selected according to the actual requirements.

Type of surface

Surface venner:Power coating(ordinary power,polyester),rolling,laminating,metal anode oxidation treatment.Can be pore panel or punching panel according to the actual requirements.

Size:

595*595mm, 605*605mm

Thickness: 0.5mm,0.6mm,0.7mm

Features:

1.Aluminium material,fireproof,waterproof,soundproof

2.Suspended installation,won't harm the base ceiling

3.Flat non-trace,splicing seamless:

4.Each plate edge have screens orientation to ensure the ceiling smoothly and beautiful.

5.Plates joining together through by keel,which make splicing seamless and engineer cover,and moisture.

6.On the back of the ceiling with the sound-absorbing paper or cotton, make it has the best sound-absorbing function.

7.Suitable for indoor,such as office buildings, schools, hospitals,supermarket, channel, banks, etc.

Specification of aluminum ceiling clip in tiles 600X600

Clip-in | Size | Height | Thickness | Edge |

(mm) | (mm) | (mm) | ||

300*300 | 10/20/25 | 0.45-1.0 | Beveled Edge/Straight Edge | |

300*600 | 10/20/25 | 0.45-1.0 | Beveled Edge/Straight Edge | |

300*1200 | 10/20/25 | 0.45-1.0 | Beveled Edge/Straight Edge | |

400*400 | 1020/25 | 0.45-1.0 | Beveled Edge/Straight Edge | |

500*500 | 10/20/25 | 0.45-1.0 | Beveled Edge/Straight Edge | |

600*600 | 10/20/25 | 0.45-1.0 | Beveled Edge/Straight Edge | |

Lay-in | 275*275 | 8/10 | 0.45-1.0 | Straight Edge |

295*295 | 8/10 | 0.45-1.0 | Straight Edge | |

575*575 | 8/10 | 0.45-1.0 | Straight Edge | |

585*585 | 8/10 | 0.45-1.0 | Straight Edge | |

585*1185 | 8/10 | 0.45-1.0 | Straight Edge |

Description:

1.Superposition joint part between main carrier and vice carrier or vice carrier and carrier is called point lap.

2.It uses lap structure to assembly, connection between joints dovetail very well. The joint face unknits and have a nice appearance.

3.There is a barb at the vice carrier joint, it can avoid loosing and falling from the infection of outside force.

4.Soleplate of main and vice carrier is zincification armor plate, which meets the national GB standard demand. We use baked paint zincifcation armor plate as baked paint panel,whoes capacity of zincification is high. It meet the national GB standard demand.

5. Raw Meterial is galvanized steel with 80-100g/sqm

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q:How to remove the aluminum ceiling, change the position of the chandelier

- And then observe the keel position, because the keel is jammed the important joints of the ceiling. Look at the last few ceilings that short in the keel position to put a short point of the ceiling on the line. And then remove the second piece is easy.

- Q:How to install the aluminum slab ceiling

- With the tape measure the length and width of your bathroom, to the building materials market to find a PVC is to do the plastic plate business, choose your favorite style or color, the toilet and your toilet length and width told the shop owner, he gave You arranged! In general, PVC board has a square meter 25-80 yuan range! For example, 30 yuan a square meter of the board, the bathroom area is 5 square meters, then 240 yuan difference can not do a good job! PVC ceiling is both beautiful and generous, easy to disassemble!

- Q:What are the precautions and corresponding regulations in the construction of aluminum slabs?

- The installation of the aluminum plate is not complicated, pay attention to Yuba, water heater, exhaust fan, hood, lamp installation sequence with a good, do not put the fan (Yuba) directly with screws installed on the aluminum plate. Otherwise the installation of the aluminum plate to open the exhaust (Yuba) owners will find a "buzzing" sound, because hanging off the aluminum plate after the top of the closed space will form a resonant cavity, regardless of fan (Yuba) mute effect How good will be expanded many times. The correct installation order is: first installed Yuba, exhaust fan, and then do aluminum hanging plate ceiling (Yuba, exhaust fan can be used with expansion bolts and wire hanging directly at the top of the coagulation. Best without wire, steel wire plasticity is poor).

- Q:How to distinguish between aluminum plate and what kind of board board

- The difference is that the surface coating is different, the lowest price of film, followed by rolling, and then the next nano. General home improvement, roller the most appropriate. If you pay attention to style with the general European-style idiots with nano-aluminum plate, modern with roller coated aluminum plate. Laminating has been useless, because easy to oxidize discoloration, according to your price on-demand purchase, personal opinion of the kind of high-end oxidation is not necessary, that is to cover a ugly, good clean fumes.

- Q:How to distinguish between the integrated ceiling aluminum plate girders good or bad

- Accessories ?????? Accessories are also a decision price factors, accessories mainly refers to the keel, and now most of the home decoration is not easy to deformation, with fire performance of light steel keel, the selection should pay attention to the thickness of the keel, good keel thickness of not less than 0.6 mm. Good keel is hot plate galvanized keel, above the snow-like pattern, strength, corrosion resistance higher. The strength of the manufacturers of the keel has its own trademark, and no-name no.

- Q:How much is the price of an inch? Pack material

- According to the brand and thickness, specifications, etc. to determine, generally the cheapest also more than 60 yuan, the thickness of only 0.4mm less than.

- Q:Including: hook, triangular keel connection, nut, big hanging, income side, triangular keel, expansion screw, screw, the main keel (light steel keel) Should have 35 square meters, how much you need, the best price it!

- Almost need 6-7 hundred dollars

- Q:What is the difference between aluminum-plastic and aluminum-plated boards?

- Aluminum-plastic plate, in fact, is the abbreviation of aluminum-plastic composite panels. Aluminum-plastic composite panel is made of aluminum alloy plate on both sides of the inside and outside, low-density polyethylene core layer and adhesive composite as one of the light wall decoration materials. As a new type of building materials, aluminum-plastic panels are widely used in building exterior decoration, signs, display panels, advertising boards, building partitions, interior wall decorative panels. Aluminum slab: a kind of new home furnishings in the 1990s, mainly used for kitchen and toilet ceiling works. As the entire process of aluminum slabs to use all-metal build, in the service life and the ability to surround, more superior to PVC materials and steel materials, at present, the aluminum plate has become a home improvement throughout the project one of the indispensable materials.

- Q:Aluminum buckle ceiling business does not make money? How much profit margins? Is it good to do a good job or a good distributor

- Distributors certainly not as agents, choose a good brand, to find a good reputation to do the manufacturers, or when he gave you a proxy, and sell good words fancy manufacturers to find manufacturers and then put the manufacturers

- Q:Kitchen aluminum plate inlaid with lights, lights do not change how to install how the equipment installed

- Go to the supermarket to buy a small sucker, buckle buckle in the corner down on a pull down, as to how to install the lamp to see what light you are.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Ceiling Clip In Type Perforated Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords