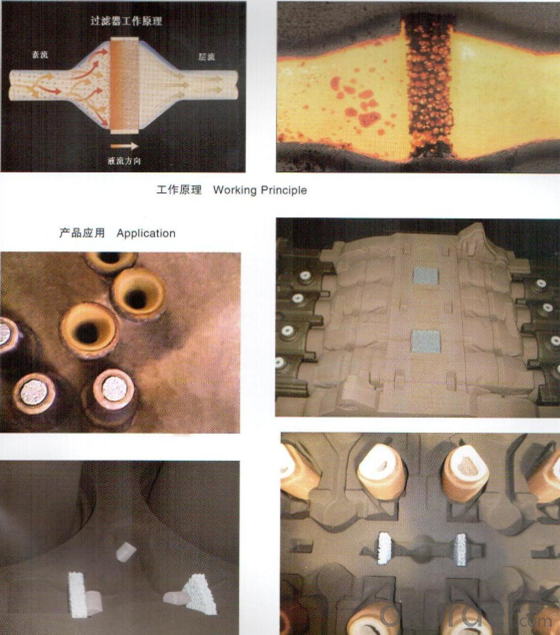

Alumina Ceramic Foam Filter for Steel Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Alumina Ceramic Foam Filter for Steel Industry

| Place of Origin: | China (Mainland) | Brand Name: | CMAX | Model Number: | |

| Material: | PU foam (polyurethane foam) | Size: | Customized | Mesh: | 10 ppi to 60 ppi |

| Property 1: | Mend structure of crystalloid | Property 2: | Reduce foreign matter | Property 3: | Stable chemical property |

| Property 4: | Stable purifying efficiency | polyurethane foam filter: | polyurethane foam |

Packaging & Delivery

| Packaging Details: | carton and pallet, or as customers' requirement |

| Delivery Detail: | 30 days after receiving the downpayment |

Specifications

Alumina ceramic foam filter

1.even aperture, high porosity, proper sinter

2.high strength of anti-flexing and anti-compression

Alumina ceramic foam filter

The product, adopted good portiforium foam and high purity ceramic , effectively removes non-metal solid mixture from aluminium and aluminium alloy fusant.

Advantages:

even aperture, high porosity, proper sinter, high strength of anti-flexing and anti-compression, effective filtering.

It is widely applied to the aluminium fusant filter equipment of continuous casting, half-continuous casting, gravity casting, and low pressure casting.

Ceramic foam filters are different from aperture specifications from 10 to 45ppi, with different sizes and shapes.

Besides the general specification ,we can offer the product according to the customers requirements.

Form A Ceramic foam filter capability

Thickness mm | Aperture PPi | Volume intensity g/cm3 | Tortuous intensity in normal temperature N/cm2

| Pressure resistence intensity in normal temperature N/cm2

| Pressure resistence intensity in high temperature N/cm2

| Refractory temperature

| Air discharging capability cm3/g

| Porosity %

|

15-100 | 10-45 | 0.35-0.45 | ≥38 | ≥80 | ≥45 | ≥1800 | ≤5 | ≥85 |

Form B 25ppi capability of typical pouring of ceramic foam filter

Specification mm | Area M2

| Maximum metal volume of pouring (kg/min) | Optimum volume of pouring (kg/min) | Typical capacity of filtering (T) |

178X178X50 | 0.0213 | 57.00 | 25-45 | 4.2 |

229X229X50 | 0.0387 | 118.00 | 35-102 | 6.9 |

305X305X50 | 0.0745 | 198.00 | 90-165 | 13.8 |

381X381X50 | 0.122 | 325.80 | 130-265 | 23.2 |

432X432X50 | 0.160 | 427.20 | 210-350 | 34.5 |

508X508X50 | 0.227 | 606.60 | 280-465 | 43.7 |

585X585X50 | 0.341 | 772.20 | 370-540 | 57.3 |

Welcome to visit our factory~

- Q:What filter material are placed in the aquarium filter?

- Submerged in water. Submersible pumps and filter cotton (often replaced by sponge) installed in one, and some brands will also be installed heaters, which become multi-purpose fish farming equipment. When working, the water is absorbed into the filter in many directions, and the filtered water is returned to the water tank by other means. This filter because of its low price and popular beginners of all ages, but the effects from the use of view, only suitable for small fish density, on the flow and filtration requirements are not high, a small aquarium, "fish" will be built in filter (especially the heating function of the filter for seedling and foster) water tank. The effect is very good. The biggest disadvantage of this device is that when it stops working, a lot of dirt stuck to the filter runs back into the water.

- Q:What is the filtration accuracy of 50nm ceramic membrane?

- The filtration accuracy is the maximum particle size that the membrane can pass through.

- Q:How much is the accuracy of 50nm ceramic membrane filtration?

- 50nm refers to the nominal pore size, but it does not mean that the holes in the ceramic membrane are 50nm, but the approximate number of holes. The size of the pores may be between 40~60 and 45 to 55nm. Generally introduced, annotated range, you can also own to detect.

- Q:Why should filter core be used in backwash of ceramic filter?

- The filter in the water filter of ceramic filter is used for filtering water.

- Q:What are the functions of honeycomb ceramic filters?

- At present, it is widely used in metallurgy, foundry industry, metal melt filtration, using mullite (cordierite) ceramic materials

- Q:Ceramic filter suddenly do not smoke, a little later on their own good, what reason?

- How old the general ceramic filter suction main reason mud cake thickness is not much of a ceramic filter plate is different, because the ceramic filter backwash water, vacuum suction and nitrate are through the distribution valve, are often the same boat". See your description, you do not know the 5 line is about "5 disc or sideways 5 rows of ceramic plates, that is completely not suction or suction effect

- Q:Principle of chemical engineering drum vacuum filter, the faster the speed, the less the amount of filtrate obtained per turn, the more the amount of filtrate obtained per unit time?

- The faster the speed is, the shorter the time required for each turn, i.e., the shorter the filtration time, the less the filtrate will be

- Q:Microporous ceramic filter plate cleaning

- For the use of a long time, the method 1, the effect is still no significant improvement, that is how to plug the ceramic filter plate regeneration? The ceramic filter plate with uneven or non sucking slurry can be removed, and oxalic acid or other acid liquid with certain concentration and certain temperature can be taken together to dredge the microporous of the ceramic filter plate. (do not recommend sulphuric acid)

- Q:Can the plate filter press pass through the filter plate?

- There are many types of pumps to be used, such as screw pumps, slag pumps, rotary pumps, piston pumps, and diaphragm pumps.

- Q:The vacuum degree of the ceramic filter is normal and the cake water is large?

- The vacuum degree of the ceramic filter is normal at about -0.08MPa. Under normal circumstances, the water content of the filter cake treated with a ceramic filter is about 10%, and the moisture content of the tail filter cake is about 15%. The water content of the filter cake increases with the increase of water content in the ceramic filter.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Alumina Ceramic Foam Filter for Steel Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords