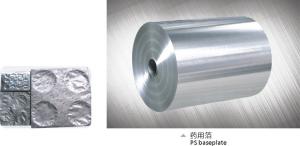

ALU PHARMACEUTICAL FOIL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

specifications:01) alloy: a3003 a110002) aluminium thickness: 0.026mm -

0.60mm03) aluminium width:a) standard width: 1,240mmb) special width:

1,300mm, 1,520mm, 1,570mm and 1,595mm are also available04) coating finish:

pvdf, polyester, acrylic05) total coating thickness:a) pvdf coating: more than

25 micronb) polyester coating: more than 18 micron06) coating hardness (pencil

hardness) more than 2h07) adhesion: 5j08) impact resistance: no cracking and

peeling09) flexibility (t-bend): 2t10) mek resistance: more than 10011) bottom

side aluminium sheet is coated with protective polyester material, an the

thickness is more than 6 micron12) minimum order: 1mt/1 x 20' fcl (about

17mt)13) certification: certificate of origin14) delivery time: 8 - 15 days after

receiving your first depositapplications:used to manufacture decorative

materials, such as aluminium composite panels, brushed panels, lampshades,

and other composite panels:1) exterior applications: wall cladding, facades,

roofs and canopies, tunnels, column covers or renovations2) interior

applications: wall cladding, ceilings, bathrooms, kitchens and balconies3)

advertisement and market applications: display platformssignboards, fascias

and shop fronts4) transport and industrial applicationspacking:export standard,

wooden splint

- Q:How long and at what tempature should i cook boneless skinless chicken breast in the oven?

- 350 degrees, 20-25 minutes depending on how thick the cut isMake sure it's covered w/ aluminum foil so it doesn't dry out!

- Q:I have the recipe, and have tried twice in the past but I must always mess up somewhere along the wayInstead of giving me the recipe as the answer does anyone know the exact process that they have tried and worksWhen do I actually refrigerate the starter? Do I make the bread before I refrigerate the first initial batch of the starter?Whats considered day one?I need a step by step that someone has tried without failMaybe I am messing up on the actual bread makingPlease help, I love this bread but cannot make it right.I hope someone can help me because both times my bread didn't taste good and I have eaten others bread and it is delicious

- Yes, we all know a Toy Poodle is realLook up recipes for Doggy Carob-chip cookies, my dog likes them.

- Q:I use some aluminium cookwareThey tend to leave black stain on countertop, table and platesHow can I wash those stain?

- My counter tops will catch any stain possible and I get those black marks from my aluminum pans also.I found that soft scrub with bleach does the trick quite well

- Q:I've tried cardboard (cereal boxes, moving boxes, etc) and plastic sheets and aluminum foil (.foil did not turn out so well)What else, something less than $1?

- Wrap tin foil around the usb wireless card not covering the metal chip, proved to increase range massively, saving lots of money.

- Q:im trying to make a cosmetic product for eyeshadow and was wondering if you could make it so when you wipe off your face with or soap or something that the glitter would just dissolve?

- Very difficult to get glitter to dissolve without using extremely corrosive solventsGlitter is a mixture of various copolymers and aluminium foil, onto which various metal salts are coated so that they reflect light in various coloursAs you can imagine, actually dissolving a plastic is something that is only really possible at elevated temepratures (greater than 120°C), and dissolving metals requires an acidI would suggest a better solution would be to allow the glitter itself to remain intact, but to use a carrier system that can easily be washed off, thereby taking the glitter with itFor example, if you were to disperse the glitter into a light colourless gel then the gel could be wiped off the face with simple soap and water, and the glitter would wash off with the gel.

- Q:with out the frostingI would like to make the green velvet cupcakes in advanceI'll be using the canned frostingany advise? also, which it is better the food coloring or icing gel paste?

- soak in some alcoholthat always helps.

- Q:What do you use for a sandwich bag when you are out and have no time to go to the store???

- I've used grocery bags, saran wrap, aluminum foil, empty bread bags tupperwareWhat else is there?

- Q:I have a frame whose rear drop out spacing is about an 1/8quot; smaller than the hub body that I want in thereI dont want to buy a new hub, or worse frameI have tried all-thread, nuts and washer rig to quot;spreadquot; the tubing but I get a spring back when I remove the rig to install the wheel.I have tried a car jack, heavy piece of cheater pipe to spread and pry.No luck with the spring back.Please help !! I can't be the only one that has this happen to them.

- what is it made of? aluminum i would expect to not be permanently bendable steel maybe more so i don;t see what else you can do try spreading it if it doesn;t stay you are stuck i wouldn;t try heat it could unpredictably change the tubing characteristics wle.

- Q:How to make aluminum bend with a concave shape?

- yes do use foil thats the easiest.try to trase something with the same shape of a boat,use your imagination!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ALU PHARMACEUTICAL FOIL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords