Al2O3,Aluminium Oxide Powder, Aluminium Powder

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Al2O3,Aluminium Oxide Powder, Aluminium Powder

Specification:

High purity AL2O3 Aluminum Oxide/ Aluminum powder

Manufacturer

Superfine

Application:

1- Used as refractory material in electronic, metallurgical,textile and oxidizing industry.

2- castable refractory product for brick,wall, plate or cover.

3- Suitable for atmospheric temperature recovering equipment.

4- A fluorine removal agent of drinking water.

5- temperature resistance above 1700 degree.

5. at high temerature, transform into alpha alumina.

aluminum oxide property:

Soluble in water white solid. Odourless. Tasteless. Qualitative very hard. Easy absorption of moisture and not ChaoXie. Both sexes oxide, soluble in inorganic acid and alkaline solution, almost insoluble in water and the polar organic solvents. The relative density (d204) 4.0. Melting point about 2000 °C.

aluminum oxide property:

Soluble in water white solid. Odourless. Tasteless. Qualitative very hard. Easy absorption of moisture and not ChaoXie. Both sexes oxide, soluble in inorganic acid and alkaline solution, almost insoluble in water and the polar organic solvents. The relative density (d204) 4.0. Melting point about 2000 °C.

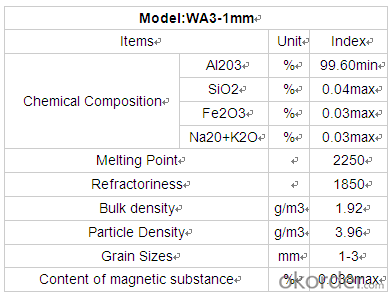

The physical and chemical analysis:

Main standard:

Alumina(industry grade) made by slkali-lime sintered,It is white powdered crystal with low assay of Ti, Mn, Zn, Cu, V, Zr, Cr, Li, Pb, B, P, etc.It is used in the production of fused salt eletrorefining aluminium, corundum eramics, refractories and other alumina chemical products.

Application of AL2O3

1. aluminium oxide for aluminium smelting, glass, ceramic industry etc.

2. aluminium oxide for refractory, coating, abrasive applications.

3. aluminium oxide for electric basal plate, desiccating agent, chemical and pharmacy industry, etc.

Product Pictures:

If you’ve any enquiry please don’t hesitate to contact us!

- Q:How long is the fire resistant limit for ultra thin fire retardant coating?

- According to the "code for fire protection design of tall buildings", the fire resistance time of the component is at the first level: 3 hours, beam: 2 hours, floor: 1.5 hours;if fire resistance level is level 2, the requirement for time of fire resistance component is the column: 2.5 hours, beam: 1.5 hours, floor: 1 hours. For fire resistant coating, fire resistance time for ultra-thin fire retardant coating is less than 1.5 hours. If the time exceeds 1.5 hours, thick fire resistive coating should be uesd.

- Q:What are the characteristics of the carbon composite refractories?

- The features of carbon composite refractories: 1. It is with an aggressive high thermal shock resistance 2. Good resistance to molten steel and slag

- Q:Why does refractory need to add coarse firstly and then add fine aggregate?

- Adding coarse aggregate is to assure its good combination with fine aggregate. This is just the experience. You don't have to ask.

- Q:How can refractory material of the electric furnace be used for longer.

- I do not know if you are referring to super high power arc furnace for steelmaking, if you are, I have a easy solution for I have been doing this work.

- Q:Where is the sizing nozzle for refractories? Just enter the line, master into!

- Hua Heng refractories in the industry reputation is good, especially in the Southern small steel sales are among the best!

- Q:How to hang the suspended brick in the refractory masonry?

- First you can weld the metal fastener of the suspended brick and then hang up the brick.

- Q:What's the B grade fireproofing material?

- B1 grade ceiling material: gypsum board, fobrous plasterboard, cement particle board, mineral wool decorative acoustic panels, glass wool decorative acoustic board, perlite decorative acoustic board, flame retardant plywood, flame retardant medium density fiberboard, rock wool decorative sheet, flame retardant wood, aluminum foil composites, flame retardant phenolic laminate, aluminum foil glass fiber reinforced plastic composite material, etc.; B1 grade wall material: gypsum board, fibrous plasterboard, cement particle board, mineral wool board, glass wool board, perlite board, flame retardant plywood and medium density fiberboard, fireproof plastic decorative sheet, nonflammable double-sided particle board, multicolor coating, flame retardant wallpaper and wall cloth, flame retardant simulated granite decorative plates, magnesium oxychloride cement prefabricated wall panels, flame retardant glass fiber reinforced plastic plates, PVC plastic clapboards, high-strength and lightweight composite wallboards, fire-retardant molded wooden composite boards, flame retardant colored artificial boards, nonflammable glass fiber reinforced plastics, etc.

- Q:Refractories for iron-making blast furnace?

- Vibrating materials, corundum brick and aluminum carbon brick will be developed. Taphole commonly use stemming, silicon carbide - graphite bricks, whose material is Al2O3-SiC-C. Medium and large sized blast furnaces in China use dense mullite bricks, castable, graphite brick. Common lining material for iron ditch is ramming mass. hearth and furnace bottom common use carbon bricks, semi-graphite bricks, charring silica bricks, corundum bricks. Blast furnace bosh and lower part of furnace stack commonly use mullite bricks.

- Q:What's the organzational structure of refractory material?

- Ingredients (harmful); phase composition. The main components of refractory material include chemical composition and phase composition. The addtional components include main crystal phase, matrix, crystal phase, chemical composition

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Al2O3,Aluminium Oxide Powder, Aluminium Powder

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords