AL2O3 85%min China Calcined Bauxite Manufacture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Company Profile

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

Since 2004, the trading volume of CNBM International has been doubled in 5 successive years owing to the support of superior corporations and effort of all staff. Meanwhile, we have established strategic partnerships with hundreds of domestic manufacturers and sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target.

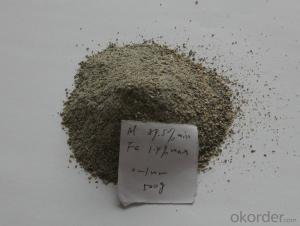

AL2O3 85%min China Calcined Bauxite Manufacture

1. Calcined bauxite

AL2O3:70% min.

FE2O3:2% max.

SIZE: 1-5MM 90% min.

china calcined bauxite manufacturer since 1999

purity of al2o3 75%-90%

rotary kiln calcined bauxite

self-owned bauxite mines

Specifications of Calcined bauxite

Grade | AL2O3 | SIO2 | FE2O3 | TIO2 | K2O+Na2O | CaO+MgO | Bulk density |

HX75 | 75min | ≤17 | ≤3.0 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.70 |

HX80 | 80min | ≤12 | ≤3.0 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.80 |

HX85 | 85min | ≤8 | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.00 |

HX86 | 86min | ≤7 | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.10 |

HX87 | 87min | ≤6 | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.20 |

HX88 | 88min | ≤5 | ≤1.8 | ≤4.0 | ≤0.25 | ≤0.5 | ≥3.25 |

HX90 | 90min | ≤3 | ≤1.8 | ≤4.0 | ≤0.25 | ≤0.5 | ≥3.3 |

Moisture(max) | 0.50% | ||||||

Size of Calcined bauxite

Section sand:0-0.3mm,0-0.5mm,0-1mm,1-3mm,3-5mm,5-8mm.

Fine powder:100#-0,200#-0,325#-0

Moh’s hardness: 7-8

Melting point:1770-2000 C

Usage of Calcined bauxite

1.Aluminium industry.

2.Precision casting.

3.Refractory industry.

4.Silicic acid aluminium firefibre

5.Mixed with magnesium oxide,it can be an nice bonding agent,especially for pouring entire steel teeming ladle lining

6.Manufacture bauxite cement,grinding abrasives.ceracmic industry,and chemical industry for making aluminium compounds

- Q:What are the main materials in concrete fireproofing material?

- it can be roughly divided into: fire-resistant coating for steel structure, finishing fire retardant paint, tunnel fire coatings, concrete fire?retardant?coating, cable refractory coating. fire-resistant coating for steel structure is divided into: Indoor ultra-thin fireproof coatings for steel structure, indoor thin steel structure fireproofing coating, indoor thick steel structure fireproofing coating, outdoor ultra-thin fireproof coatings for steel structure, Outdoor thin steel structure fireproofing coating, outdoor thick steel fireproofing coating. I hope it can help you. Hope to adopt my opinion Thank you! )

- Q:What is the criterion of entry of refractory clay industry?

- Standard sizes of refractory bricks in our country are: 230mm × 114mm × 65mm; ordinary brick: 240 * 115 * 53, Building blocks: (blind holes, through-holes) 240 * 390 * 190 * 190,240 * 190,240 * 190,190 * 90 * 190 * 390 * 190,190 * 190,190 * 190,190 * 190 * 90 * 190, 140 * 390 * 190,140 * 190,990 * 190 * 200 * 400, from 0 * 390 * 190 * 190,90 * 190,90 * 90 * 190. There is also an interlocked hollow blocks: 90 * 200 * 200 * 400,90 * 245,90 * 200,90 * 200 * 200 * 100, 90 * 200 * 290,150 * 275,150 * 200 * 200 * 200, 150 * 200 * 100, 150 * 200 * 290.

- Q:Which refractory quality inspection authority is good?

- Of course, it is Research Institue of Refractory Materials in Luoyang, Henan. In fact, what we want is accuracy and authority. Quality and inspection costs, which is more important?

- Q:What are the characteristics of thealuminium oxide refractory?

- Alumina refractory are characterized by uniform granularity, mobility, good dispersity. And it has good acid and alkaline slag erosion resistance, high strength, abrasion resistance, high melting point, erosion resistance , anti-flush and excellent thermal shock resistance.

- Q:As for fireproofing material rock wool and glass wool, which one is better?

- First of all, glass wool and rock wool fireproof materials, rock wool and glass wool belong to Class A fireproofing rating, secondly, rock wool can endure high temperature of 800 degrees, glass wool high temperature of 450 degrees, again,unit weight of rock wool is relatively heavier and unit weight of glass wool is lighter, finally, glass wool has better waterproof performance.

- Q:How long is the duration of fire resistance that fireproof door of level B can endure?

- Level B refers to the fire resistance rating and different hours in fireproofing of the fireproof door. Fireproof door of level A can endure fire for 1.5 hours while level B 1.2 hours

- Q:I am a refractory material manufacturer, sold products, money is always not back, anxious to die, what is the way?

- Many manufacturers are facing the same problem, difficult to find the order, order the payment contract is more difficult, it is difficult to have binding, the better solution is to seek third party secured transactions, see the whole production or see full delivery

- Q:Could you tell me the fire-resisting time of class B fire proof door?

- The fire-resisting time of class B fire proof door is 1h and thickness of door can't be lower than 45mm.

- Q:what is best for making refractory insulation for Blast furnace, hot stove.

- clay brick, insulating brick can endure relatively high temperature and last longer than the general fireproof fiber.

- Q:What thickness is needed of the ultra-thin fireproof paint with a fireproof time of 2.5 hours?

- The thickness of steel structure fire retardant coating hasn't been regulated in the steel structure application specification (CECS24:90). The above thickness refers to a certain thickness that must (at least) achieve a certain time of the fire resistance. The thickness of fire-retardant coating in engineering is generally determined according to factory inspection report. We use thin steel structure fire retardant coating: 2.5 hours' fire resistance with the thickness of 4.9 mm; 2.0 hours' fire resistance with the thickness of 3.5 mm; 1.5 hours' fire resistance with the thickness of 1.75 mm; 1.0 hours' fire resistance with thickness of 1.17 mm. I hope I can help you.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AL2O3 85%min China Calcined Bauxite Manufacture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products