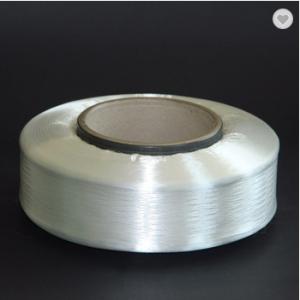

Air Jet Textured polyester filament yarn, aty yarn

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Material: | 100% Nylon,Nylon | Yarn Type: | DTY | Pattern: | Dyed |

| Style: | Core Spun Yarn,Textured yarn, stretch yarn | Feature: | Anti-Bacteria,Anti-Pilling,High Tenacity,Moisture-Absorbent,Polyester textured yarn | Use: | Hand Knitting,Knitting,Sewing,Weaving,Weaving, Knitting |

| Twist: | 120 | Evenness: | good | Yarn Count: | 70D |

| Strength: | strong | Place of Origin: | Jiangsu China (Mainland) | Brand Name: | Longjiang |

| Model Number: | NJYSY-NY399 | Commodity: | Nylon DTY yarn | Colour: | Dyed |

Packaging & Delivery

| Packaging Detail: | Raw white/dope dyed yarn 5.5kg-6kg/bobbin, 6bobbins/CTN, 33KG/CTN; dying yarn 1kg/cone, 25kgs/ctn |

| Delivery Detail: | 15 to 20days after deposit received |

Specifications

aty:

Strongly technology support and serious produce manage, good quality control system!air jet textured polyester filament

aty :

We can supply you air jet textured polyester filament yam ranged from 100D-3000D and various color dope dyed. Pls check the detailed information about our produce:

Technical parameter:

(1) Breaking Strength: 2.3CN/DTEX

(2) Breaking Elongation: (20+/- 5) %

(3) Oil Content: no more 1.5%

(4) Boling Water Shrinkage: no more 7%

Detailed packing: measurement-720mm*490mm*300mm/carton, 6tubes in each carton. 90% cartons with tubes of standard weight, each tube weigh from 3kgs to 4kgs depends on different specification. 10% cartons with more than 6 tubes of nonstandard weight, each tube weigh from 1kg-3kgs depends on different specification.

Container load (per 40HQ): about N.W 14500kgs in 600cartons

It can be used for office furniture decorating fabrics, atuo decorating fabrics, curtain etc.

Pls contact with us without hesitate, if you have any inquires or questions.

Thank you advance!

- Q:How does the textile shake the knot?

- 2, the right hand will be the yarn frame on the twisted yarn head to find, put the right hand thumb food fingers pinch the yarn, the two yarn into a cross shape. 3, the right hand thumb fingers pinch the top of the hammer head, along the left hand around the thumb, and then pressure in the cheese under the yarn head.

- Q:Is the price of oil and textile yarn?

- In fact, before I read the book, I learned that the consumer market, many products in fact, pricing is not dependent on product costs, but the competitors price strategy.

- Q:What is the difference between textile sizing and paper making?

- The modified starch used in papermaking is mainly: acid modified starch (surface sizing), oxidized starch (surface sizing, coating), phosphate starch (surface sizing, coating), oxidized acetate starch (coating) Cationic starch, amphoteric starch (pulp added), grafted starch (coated. Market less) a technology is not up to standard, and then a cost can not accept

- Q:In the textile fabric, mesh cloth and the difference between the Bali yarn is what

- It has a unique elasticity function. Mesh fabric mesh structure, in the production process after a high temperature stereotypes, when subjected to external forces, can follow the direction of force extension, when the pull force to reduce the withdrawal, the mesh can be restored to the original shape. Mesh cloth is made of tens of thousands of polymer synthetic fiber yarn, refined from the oil out. Made of knitted weave, it is not only firm, able to withstand high strength of the tension and tear.

- Q:What is yarn support?

- Metric count (Nm) - At a given moisture regain, 1 gram of yarn length is a meter multiple, that is, 1 gram of heavy yarn is just 1 meter long, 1 (g) yarn, 1 gram heavy yarn Length of 200 meters long, the fineness of the yarn 200

- Q:Calculation formula of yarn twist

- Yarn twist refers to the yarn to have a certain strength, elasticity, elongation, gloss, feel and other physical and mechanical properties, must be twisted by changing the yarn, the fiber structure to achieve yarn twist, in fact, is the use of cotton yarn cross-section To produce a relative angular displacement, so that the original straight parallel fibers and yarn shaft tilt to change the yarn structure

- Q:What is the process of towel in the textile?

- Determine the yarn count, warp and weft density, the number of warp yarns and weft yarns (especially yarn-dyed), with a number of pieces, wearing a reed method, jacquard to determine the installation of wear method (in layman's terms, , Wear, mix wear method), reed width, shaft width, yarn consumption, hair times, under the specifications and weight, and so on

- Q:How does textile twist yarn identify?

- Therefore, in the detection of the composition of the textile, we can extract several from the fabric edge of the warp and weft, untwisted to form a loose as a sample, on the fire burning

- Q:Textile waste silk (abandoned side yarn) what purpose ah?

- Traditional textile technology and equipment are complicated, rising production costs, to enable people to find new technologies

- Q:What are the benefits of the steaming machine to the textile industry?

- Quick steaming box - treatment effect: 1. Relaxation, shaping, humidification. 2. Increase the yarn strength, reduce the fracture (cotton yarn breaking strength will increase by 10%, wool yarn elongation increased by 30%); Cotton yarn feathers fall by 30-45%; 4. Yarn moisture uniformity, control moisture regain high precision;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Air Jet Textured polyester filament yarn, aty yarn

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords