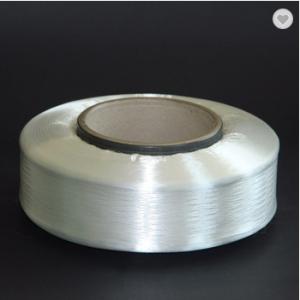

100% Nylon Yarn

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 TON m.t.

- Supply Capability:

- 3000 Ton/Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of 100% Nylon Yarn:

1)100% nylon yarn

2)dty 70/1 70/2 RW SD

2)AA grade Invista chips

4)semless underware

5)4.5kg/cone,6 cone/ctn

Feature Details of 100% Nylon Yarn:

Item | Nylon drawn textured yarn(DTY) |

Specification | 15D-300D |

Material | 100% nylon |

Luster | Bright/Semi-dull/Dull |

Twist | S twist/Z teist,or two ply |

Color | Raw white |

Grade | AA |

Equipment | RPR,BARMAIG MACHINES |

MOQ | 500kg |

Payment terms | FOB Shanghai or FOB Ningbo |

Applications | Avalialbe for hosiery,stocking,socks,seamless underwear, knitting,weaving,warping,sering,weft,lace,swimwear,sports suits and jacquard wave. |

Superiority | High strength,good elasticity,good yarn evenness,no broken fllament. |

- Q:On the number of textile yarns

- Is often said that the British count, English: SIZE, all commonly used S to do short.

- Q:Textile spinning yarn should be done first what to do

- To solve the knowledge of the process with a single process and to provide a single process with a professional software system, making the merchandiser really from the complex with a single transaction freed, thereby improving the business with the single management level

- Q:What is the meaning of the yarn?

- To make a hair is to dye the yarn through the machine into a cheese, shaking the yarn or cheese yarn re-coiled into the specified weight of the yarn process.

- Q:What is the textile bobbin?

- A plurality of holes are formed in the tube wall of the bobbin so that the cheese yarns wound around the bobbin are easily humidified by these holes.

- Q:What is the yarn?

- Yarn is a variety of textile fibers processed into a certain fineness of the product, used for weaving, rope, line, knitting and embroidery.

- Q:What is the yarn inside the textile industry is what kind of yarn?

- Direct dye can be stained, is the natural fiber. And then go to the performance of the fiber, the dissolution test, to come to a certain type.

- Q:What is Artex and Artex Products?

- Analysis of the industry that, with the improvement of living standards and aesthetic concepts, foreign Artex product market will be further expanded, the development potential is huge.

- Q:What are the differences between the yarn and the yarn of the yarn?

- C21SDK: semi-combed yarn YC21SDK: semi-combed yarn cotton yarn is made of cotton fiber spinning process by the yarn, after the joint stock processing known as cotton thread. According to the different spinning process, can be divided into carded yarn and combed yarn.

- Q:What is the diameter of a yarn of 40 yarns?

- Where 0.040 is the common diameter coefficient of the medium cotton yarn; if the high diameter cotton yarn (fine cotton yarn) is the common diameter coefficient is 0.037; this coefficient can be based on the yarn volume specific gravity (g / C㎡) formula.

- Q:What is the knitting yarn and the woven gauze?

- Knitted cloth needs a soft feel so the need for twist is relatively small and woven because the warp need to wear reed lift friction need a high strength so twist requirements are relatively large! In short the general fine gauze is a bridge-a-woven, mesh structure is knitted

1. Manufacturer Overview |

|

|---|---|

| Location | Zhejiang,China |

| Year Established | 1997 |

| Annual Output Value | |

| Main Markets | North America, South America, Western Europe, eastern Europe, east Asia, central Asia, southeast Asia, the Middle East, Africa, Oceania |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

100% Nylon Yarn

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 TON m.t.

- Supply Capability:

- 3000 Ton/Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords