AA1xxx Mill-Finished Aluminum Coils C.C Quality Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of AA1xxx Mill-Finished Aluminum Coils C.C Quality Used for Construction Description

AA1xxx Mill-Finished Aluminum Coils C.C Quality Used for Construction is one semi-finished aluminium material. This strip can be rolled down to aluminium foil.The final thickess can be 5-20 microns. Aluminium foil is soft, ductile and with a silver-white luster which can be widely used in a large scare of fields.

2.Main Features of AA1xxx Mill-Finished Aluminum Coils C.C Quality Used for Construction

1)excellent quality,good credit

2)competitive price,comfortable service

3)Samples for free

4)fast delivery,small order accepted

5)Good rust resistance

6)clean, flat, no wrinkle, no scratch, oil free.

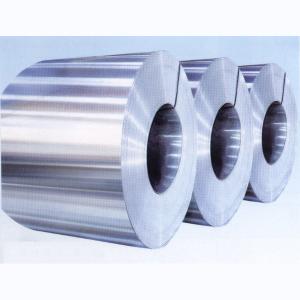

3.AA1xxx Mill-Finished Aluminum Coils C.C Quality Used for Construction Images

4.AA1xxx Mill-Finished Aluminum Coils C.C Quality Used for Construction Specification

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc. |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AA1xxx Mill-Finished Aluminum Coils C.C Quality Used for Construction

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q:What are cold rolling aluminum coil and hot rolling aluminum coil? What are their features?

- If the rolling temperature is above the crystallization one, it is hot rolling, otherwise it is cold rolling.

- Q:What is the reason for the grooves that go around the circumference of a tin/aluminium can? It can't be for grip because they're covered with paper anyway and i don't think it would make much difference.

- If they didn't, they would easily be crushed during shipment. It makes them much stronger to have the grooves. Norrie's got a good point.

- Q:0.6mm insulation aluminum coil price insulation aluminum coil where to buy the most assured?

- If the surface of the aluminum color, it is directly on the Internet search color coated aluminum roll can be.

- Q:How much is the rust-proof and thermal insulation aluminum coil?

- 3003 alumal alloy is the best and common rust-proof and thermal insulation aluminum coil. The price depends on the thickness and width you need.

- Q:What is the typical electrical resistivity of aluminum coils?

- The typical electrical resistivity of aluminum coils is approximately 2.65 x 10^-8 ohm-meters. Aluminum is known for its low resistivity, making it an excellent choice for electrical conductors. The low resistivity allows for efficient transfer of electric current through the coils, minimizing energy loss and heat generation. This property makes aluminum coils widely used in various electrical applications, such as transformers, motors, and generators.

- Q:The specification of thermal insulating aluminum coil

- 4-0 In general, the chemical engineering products for thermal insulation is 0. According to the International standard, the thickness tolerance is +-5%.02MM. according to industrial standard, it is +-0. The production crafts are embossed and plain sheet.

- Q:Are aluminum coils suitable for pharmaceutical packaging?

- Yes, aluminum coils are suitable for pharmaceutical packaging due to their excellent barrier properties, lightweight nature, and ability to protect sensitive drugs from external factors like moisture, light, and oxygen. Additionally, aluminum coils are easily moldable, making them ideal for creating customized packaging shapes and sizes to meet specific pharmaceutical requirements.

- Q:Can aluminum coils be used in architectural mesh applications?

- Yes, aluminum coils can be used in architectural mesh applications. Aluminum is a versatile and lightweight material that is commonly used in construction and architectural projects. It offers numerous benefits for architectural mesh applications including high strength-to-weight ratio, corrosion resistance, and ease of installation. Aluminum coils can be formed and fabricated into various shapes and sizes to create intricate architectural mesh designs. The coils can be woven, welded, or expanded to create different patterns and textures, allowing for flexibility in design and customization. Architectural mesh applications using aluminum coils can be found in a wide range of structures such as facades, partitions, ceilings, sunscreens, and safety barriers. The mesh can provide aesthetic appeal, privacy, sun shading, ventilation, and even security. In addition to its aesthetic and functional qualities, aluminum is also a sustainable choice for architectural mesh applications. It is a highly recyclable material, and its lightweight nature reduces transportation and installation costs, making it an environmentally friendly option. Overall, aluminum coils are an excellent choice for architectural mesh applications due to their durability, versatility, and sustainability. Whether it is for commercial, residential, or public spaces, aluminum mesh can enhance the visual appeal and functionality of architectural designs.

- Q:How are aluminum coils used in gutter systems?

- Aluminum coils are commonly used in gutter systems for their durability and resistance to corrosion. Gutter systems are designed to collect rainwater and direct it away from the roof and foundation of a building to prevent water damage. Aluminum coils are used to create seamless gutters that are custom-fitted to the dimensions of a particular structure. The process begins with an aluminum coil that is fed through a specialized machine called a gutter machine. This machine forms the coil into the shape of a gutter, typically in a continuous length that can extend the entire length of the roofline without any seams. The coil is shaped to create a trough-like structure with a slight slope to allow water to flow easily towards downspouts. Aluminum is an ideal material for gutter systems as it is lightweight yet strong, making installation easier and reducing the risk of sagging or bending. It is also resistant to rust and corrosion, ensuring the longevity of the gutter system even in harsh weather conditions. Additionally, aluminum can be easily painted or coated to match the aesthetic of the building. Once the seamless gutters are formed from the aluminum coil, they are typically secured to the edge of the roofline using hangers or brackets. Downspouts are then attached to the gutters at strategic points to direct the collected rainwater away from the building's foundation. These downspouts can also be made from aluminum coils, ensuring a seamless and cohesive appearance throughout the entire gutter system. In summary, aluminum coils are used in gutter systems to create seamless gutters that provide effective and efficient water drainage. Their durability, resistance to corrosion, and ease of installation make them a popular choice for gutter systems in residential, commercial, and industrial buildings.

- Q:What are the different pre-treatment methods for aluminum coils?

- There are several different pre-treatment methods that can be used for aluminum coils. These methods are designed to prepare the surface of the coils for further processing or coating. One common pre-treatment method is degreasing. This involves removing any oils or greases that may be present on the surface of the aluminum coils. Degreasing can be done using solvents or alkaline cleaners, depending on the specific requirements of the application. Another pre-treatment method is etching. Etching is used to remove any surface oxides or contaminants that may be present on the aluminum coils. This process can be done using acidic solutions or with the help of mechanical methods such as sandblasting or brushing. Phosphating is another pre-treatment method that is commonly used for aluminum coils. Phosphating involves applying a phosphate coating to the surface of the coils. This coating helps to improve the adhesion of subsequent coatings or paints, as well as providing corrosion resistance. Conversion coating is also a popular pre-treatment method for aluminum coils. Conversion coatings are thin layers of inorganic compounds that are formed on the surface of the coils. These coatings improve the adhesion of subsequent coatings or paints, as well as providing corrosion resistance. Some common conversion coatings used for aluminum include chromate, chromate-free, or anodizing. In summary, the different pre-treatment methods for aluminum coils include degreasing, etching, phosphating, and conversion coating. Each method serves a specific purpose in preparing the surface of the coils for further processing or coating, and the choice of method will depend on the specific requirements of the application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AA1xxx Mill-Finished Aluminum Coils C.C Quality Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords