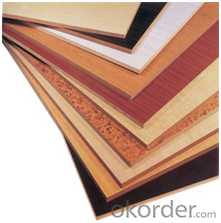

2.0MM 3.0MM Bleached poplar plywood for arts crafts and furniture usage

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 mm

- Supply Capability:

- 30000 mm/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plywood for furniture usage

Name | commercial plywood | |

Size | 1220x2440mm,1250x2500mm,915x2135mm,800x2140mm or as Agreed | |

Thickness | 2.5mm—25mm | |

Thickness Tolerance | ≤6mm | ±0.2mm to ±0.3mm, |

6mm—25mm | ±0.4mm to ±0.5mm | |

Core | Poplar,Eucalyptus, birch , combi or as agreed. | |

Face/Back | okoume,bingtangor,Massawa,PLB,poplar, keruing, pine,beech,oak etc | |

Glue | MR, WBP(E0, E1, E2). | |

Grade | BB/BB,BB/CC ,CC/CC or As Agreed | |

Moisture | 8%-14% | |

Usange | Decoration, Furniture, package | |

Package | Inter packing: 0.20mm plastic bag. | |

Outer packing: pallets are covered with plywood or carton and then steel for strength. | ||

Conveyance | 20’GP | 8pallets/ 22m³ |

40’GP | 16pallets/ 42m³ | |

40’HQ | 18pallets/53m³ | |

Delivery time | Within 15 days on receipt of deposit or original L/C. | |

Min Order | 1X40’FCL | |

Price terms | FOB, CNF, CIF,CIP | |

Payment terms | L/C at sight, T/T30% as deposit | |

Supply ability | 5500 cubic meters/month | |

What is Detail of our product Plywood?

Face/Back: Yellow Hardwood

Core: poplar, birch, hardwood, combi, pine

Glue:E1, E2, MR, WBP, Melamine

Surface Finishing: Pine, Poplar, Bintangor, Red Hardwood,Okoume

Grade: BB/BB, BB/CC, CC/CC,CC/DD,DD/EE

Size:1220*2440mm, 915*2135mm, 1250*2500mm or as your requested

Thickness:1.6mm--40mm

Purpose: Packing/Furniture/Construction/Decoration etc

- Q:What is the sandwich panel, sandwich board what is the use of what the characteristics of sandwich panels

- Sandwich panels, composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the polymer core insulation composition, easy to install, light and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor. Sandwich panels are a common product in the current building materials, not only good flame retardant and environmentally friendly Sandwich board English name: laminboard Sandwich panel products are composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the composition of the polymer core insulation. These sandwich panels are easy to install, lightweight and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor. [1] The formation of the outer steel plate takes full account of the structural and strength requirements, and take into account the aesthetic, the inner layer of the formation of flat to meet the needs.

- Q:OKorder Wang Teng color steel production and sales of a variety of color steel plate, Caigang tiles, Caigang rock wool sandwich panels, Caigang polyurethane sandwich panels, Caigang foam sandwich panels, Caigang extruded sandwich panels, color Steel paper honeycomb sandwich panels, galvanized sheet, floor board, Caigang sandwich panels, C steel, color steel activities, and other products.

- Energy-saving insulation: thermal insulation superior performance, the same thickness of the insulation effect is 2 times the EPS board. ? Flame retardant: The product has passed the "National Fixed Fire Extinguishing System and Refractory Component Quality Supervision Center", the combustion level to GB8624 B2 level standards. ? Sound insulation: sound absorption is good, on the rain, hail and other impact caused by the sound has a subtractive effect. ? Waterproof rust: a large span, fast drainage, waterproof effect is good; screw hidden, easy to rust, to extend the useful life of the plate. ? Beautiful economy: beautiful appearance, rich colors; reduce material loss, save construction time and project costs. ? Construction of fast: polyurethane sheet is a highly controlled plant in the factory environment, the quality of production, quality and stability; construction fast, the application has more than 35 years.

- Q:Color steel tile foam sandwich board model is how the classification

- Common sandwich panels: foam sandwich panels, rock wool sandwich panels, polyurethane sandwich panels. Common specifications: roof board 980, wall board 950. Common thickness: 50mm, 75mm, 100m.

- Q:Eps sandwich board and Caigang sandwich board is not two kinds of materials to the two of the price?

- Yes, EPS is glass steel surface, color steel sandwich board is color steel surface, EPS expensive, the difference is about 100 per meter

- Q:What are the requirements for the use of foam sandwich panels for fireworks

- Fire will not be used now

- Q:Plan to use Caigang sandwich panels to do the roof. The wall is brick wall. Ask how the sandwich panel is fixed on the brick wall ah?

- Wall to do reinforced concrete ring beam cap, and then fixed on the ring beam C-keel, sandwich plate fixed on the keel, complete.

- Q:Color plate sandwich panel 75mm, 0.

- The 75MM is the insulation thickness of the insulation board .050MM is the thickness of the insulation board with the color of the plate, the professional point should be called on the next 5, or what, is the top of the top plate thickness, the next is the next look at the house To the thickness of that side If you are the wallboard, that is, two sides are flat look, 0.50 is a side of the color plate thickness, usually outside the house to see that side, the house did not explain the thickness of the normal and outside the same thickness, Hope you can see,

- Q:What is the difference between the board and the core board? Usually where the place with sandwich panels where the use of laminates, such as the use of the shoe is the board, wardrobe with a sandwich panel? So what is the difference between the two

- Daxing board is made of two pieces of veneer stagnant stitching wood. Daxin board price is cheaper than the core board, the vertical (to the core material to distinguish) bending strength is poor, but the lateral bending pressure The strength is more ... but the general is best not to choose! 2. Plywood, also known as plywood, some people called the carefully board. Three or more layers by 1mm thick veneer sheet made of hot pressing. Plywood is generally divided into 3mm, 5mm , 9mm, 12mm, ... Plywood Optional plywood is made of multi-layer veneer staggered arrangement of the sheet. The outermost front panel is called the panel, the reverse is called the back plate. Core board.

- Q:What is the difference between the ecological board and the sandwich board? Which is used to decorate better, what is the price? What are the top ten brands of the two boards?

- The ecological board is made of natural mineral stone powder and natural fiber as the basic raw material, through the inorganic gel technology modification process, through the mold, natural curing molding for the environmental protection and energy saving new materials, which does not contain formaldehyde, toluene inorganic natural environmental performance, Combined with the surface of the natural texture and sustained and efficient negative oxygen ion release, to achieve its natural properties of green building materials. Sandwich panels, composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the polymer core insulation composition, easy to install, light and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor.

- Q:What is the glue used in color steel sandwich panels?

- On the machine is the production of two-component, also known as black and white plastic. Artificial compound with a single component. Very expensive.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

2.0MM 3.0MM Bleached poplar plywood for arts crafts and furniture usage

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 mm

- Supply Capability:

- 30000 mm/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords