1mm thick Stainless Steel Sheet 304 price for furniture

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

304 stainless steel background

Type 304 stainless steel is a T 300 series stainless steel austenitic. It has a minimum of 18% chromium and 8% nickel, combined with a maximum of 0.08% carbon. It is defined as a Chromium-Nickel austenitic alloy. Grade 304 is the standard "18/8" stainless that you will probably see in your pans and cookery tool

| Products Name | 1mm thick stainless steel sheet 304 price for furniture |

| Mill Brand | TISCO |

| Standard | AISI/ASTM/DIN/EN/JIS/GB |

| Surface(Finish) | NO.4/2B/HL/Mirror/BA |

| Treatment | Cold rolled |

| Edge | Slit or Mill |

| Thickness | 1mm |

| Width | 800mm~1500mm |

| Length | 1000mm~6000mm |

| Package | Fine Package: Waterproof cover, wooden plate, iron protection on the edge, pallet. |

| Standard export pakcage: Waterproof cover, Pallet, Iron Belt | |

| Payment Terms | 30% in advance and balance before shipment by T/T |

| 50% in advance and balance against B/L copy. | |

| 100% L/C or 30% T/T and Balance against L/C original at sight. | |

| Delivery time | 7 working days normally after deposit received or L/C original at sight, ajusted according to particular case |

| Quotation Validity | 7 days |

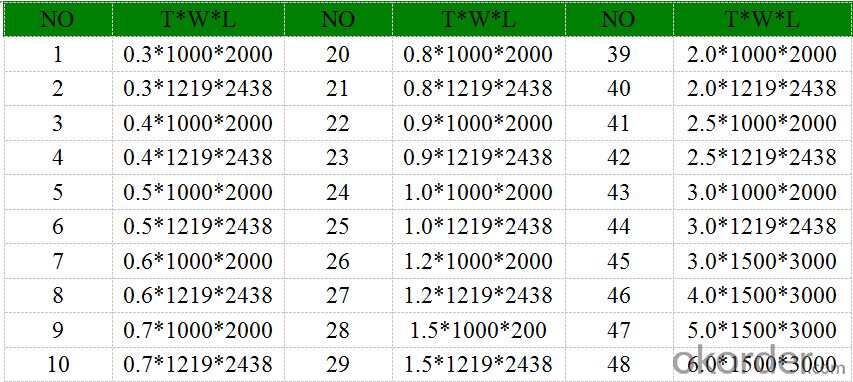

Regular sizes: Slit edge. Cold rolled.

Characteristics of 304 stainless steel sheet

- Forming and welding properties

- Corrosion/oxidation resistance thanks to the chromium content

- Deep drawing quality

- Excellent toughness, even down to cryogenic temperatures which are defined as very low temperature.

- Low temperature properties responding well to hardening by cold working

- Ease of cleaning, ease of fabrication, beauty of appearance.

Chemical Composition of 304 stainless steel sheet

Type 302 | Type 304 | Type 304L | Type 305 | |

Fe | 64.99-74% | 64.99-74% | 64.99-74% | 64.99-74% |

Cr | 17% | 18% | 18% | 17% |

Ni | 8% | 8% | 8% | 8% |

Mn | 2% | 2% | 2% | 2% |

N | 0.10% | 0.10% | 0.10% | - |

S | 0.03% | 0.03% | 0.03% | 0.03% |

C | 0.15% | 0.08% | 0.03% | 0.12% |

Si | 0.75% | 0.75% | 0.75% | 0.75% |

P | 0.045% | 0.045% | 0.045% | 0.045% |

- Q:What are the benefits of using brushed stainless steel sheets in hospitality design?

- There are several benefits of using brushed stainless steel sheets in hospitality design. Firstly, brushed stainless steel sheets add a sleek and modern aesthetic to any space. The brushed finish creates a unique texture and visual appeal, making it a popular choice in contemporary design. This material can elevate the overall look and feel of a hospitality establishment, giving it a sophisticated and upscale ambiance. Secondly, brushed stainless steel sheets are highly durable and long-lasting. Stainless steel is known for its resistance to corrosion, scratches, and stains. In a high-traffic environment like a hotel or restaurant, where there is constant use and potential for spills, this durability is crucial. These sheets can withstand the wear and tear of daily use, ensuring they maintain their pristine appearance for years to come. Thirdly, brushed stainless steel sheets are easy to clean and maintain. They are non-porous, meaning they do not absorb liquids or odors. This makes them hygienic and suitable for use in hospitality settings where cleanliness is of utmost importance. A simple wipe down with a mild detergent is usually sufficient to remove any dirt or smudges, making it a practical choice for busy establishments. Additionally, brushed stainless steel sheets are available in a variety of finishes and colors, allowing for creative customization. This versatility enables designers to incorporate them into various design schemes, whether it be a minimalist, industrial, or even a more traditional look. The ability to choose from different textures and shades ensures that brushed stainless steel sheets can seamlessly integrate with the overall design concept of a hospitality space. Lastly, brushed stainless steel sheets are environmentally friendly. Stainless steel is fully recyclable, making it a sustainable choice in design. By opting for this material, hospitality establishments can contribute to reducing waste and minimizing their environmental footprint. In conclusion, the benefits of using brushed stainless steel sheets in hospitality design are numerous. From its aesthetic appeal and durability to its ease of maintenance and environmental sustainability, this material is an excellent choice for creating a stylish and functional space in the hospitality industry.

- Q:Can stainless steel sheets be used for outdoor signage or billboards?

- Yes, stainless steel sheets can be used for outdoor signage or billboards. Stainless steel is highly durable, weather-resistant, and corrosion-resistant, making it an excellent material choice for outdoor applications. It can withstand harsh weather conditions, including rain, snow, and UV exposure, without deteriorating or fading. Additionally, stainless steel sheets can be easily fabricated and customized to create visually appealing and long-lasting outdoor signage or billboards.

- Q:Stainless steel plate laser cutting how to charge?

- It's plasma cutting... In fact, if the process is not required, you can buy a hand grinder with cutting pieces.

- Q:Can stainless steel sheets be used for water tanks?

- Yes, stainless steel sheets can be used for water tanks. Stainless steel is a popular choice for water tanks due to its corrosion-resistant properties. It is highly resistant to rust and can withstand exposure to water and moisture without deteriorating. Stainless steel is also hygienic, as it does not react with water or leach any harmful substances into it. Additionally, stainless steel tanks are durable and long-lasting, making them a reliable option for storing water. Overall, stainless steel sheets are a suitable material for constructing water tanks, providing a safe and reliable storage solution for water.

- Q:How do you prevent warping of stainless steel sheets?

- To prevent warping of stainless steel sheets, there are several measures that can be taken: 1. Proper storage and handling: Stainless steel sheets should be stored in a clean and dry environment, away from any sources of moisture or excessive heat. It is important to handle the sheets with care, avoiding any unnecessary bending or pressure that could lead to warping. 2. Correct welding techniques: When welding stainless steel sheets, it is crucial to use the appropriate techniques and procedures. Proper heat control and weld placement can help minimize the risk of warping. Preheating the sheets before welding can also help prevent distortion. 3. Stress relieving: This process involves heating the stainless steel sheets to a specific temperature and then cooling them slowly. Stress relieving helps to eliminate residual stresses that could lead to warping. 4. Support during machining: When machining stainless steel sheets, it is important to provide proper support to prevent warping. This can be achieved by using clamps or fixtures to securely hold the sheets in place. 5. Minimize heat exposure: Excessive heat can cause stainless steel sheets to warp. Therefore, it is important to avoid prolonged exposure to high temperatures during processes such as cutting, grinding, or forming. Using coolants or lubricants during these processes can help dissipate heat and minimize the risk of warping. 6. Choosing the right grade and thickness: Selecting the appropriate grade and thickness of stainless steel sheets for a specific application is essential. Thicker sheets generally have more resistance to warping, while certain grades of stainless steel may be more prone to distortion. Consulting with a materials expert or engineer can help in selecting the right stainless steel sheets for a particular project. By implementing these preventive measures, the risk of warping stainless steel sheets can be significantly reduced, ensuring their integrity and longevity.

- Q:Can stainless steel sheets be used for sound insulation?

- Yes, stainless steel sheets can be used for sound insulation to some extent. While stainless steel is not the most effective material for soundproofing, it does have some sound-dampening properties due to its density and ability to reflect sound waves. However, for optimal sound insulation, it is recommended to use specialized soundproofing materials designed specifically for this purpose.

- Q:Can stainless steel sheets be used for decorative room dividers or partitions?

- Yes, stainless steel sheets can be used for decorative room dividers or partitions. Stainless steel is a versatile material known for its durability, strength, and resistance to corrosion, making it a popular choice for various applications. When used as room dividers or partitions, stainless steel sheets can add a sleek and modern aesthetic to any space. They can be customized with different finishes, such as brushed, mirrored, or patterned, to create a unique and decorative look. Stainless steel dividers or partitions are also easy to clean and maintain, making them a practical choice for high-traffic areas or commercial spaces. Overall, stainless steel sheets offer both functionality and style, making them suitable for use as decorative room dividers or partitions.

- Q:What are the specifications of stainless steel plates? Are they the same width?

- Generally look at the thickness of 0.3-3.0mm, width of 1000/1219/1500. Thickness of 3 or more, with 1240/1250/1500/1800/2000 width. It can be cut as required.... So the purchase is still more flexible.

- Q:Can stainless steel sheets be used for outdoor applications?

- Yes, stainless steel sheets can be used for outdoor applications. Stainless steel is highly resistant to corrosion, making it an ideal material for outdoor use. It can withstand exposure to moisture, saltwater, and extreme weather conditions without rusting or deteriorating. Stainless steel sheets are commonly used in outdoor structures such as fences, handrails, roofs, and cladding. They are also used in outdoor appliances, equipment, and decorative elements. Additionally, stainless steel sheets can be painted or coated to further enhance their resistance to outdoor elements and to match the desired aesthetic. Overall, stainless steel sheets are a durable and reliable choice for outdoor applications.

- Q:Can stainless steel sheets be used for elevator floors?

- Yes, stainless steel sheets can be used for elevator floors. Stainless steel is a durable and corrosion-resistant material that is commonly used in various applications, including elevator interiors. Stainless steel sheets provide a sleek and modern look to elevator floors while also offering excellent resistance against wear and tear, stains, and impact. Additionally, stainless steel is easy to clean and maintain, making it a practical choice for elevator floors that experience heavy foot traffic.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1mm thick Stainless Steel Sheet 304 price for furniture

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords