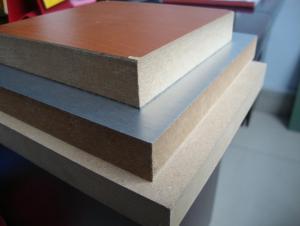

18mm Both Sides Melamine MDF for Furniture or Decoration

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 200000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Melamine Faced MDF

size | 1220*2440mm |

thickness | 18mm |

length/width tolerance | +/- 0.5mm |

thickness tolerance | +/- 0.2mm |

glue | E2 |

moisture | 6~12% |

packing | seaworth export pallet packing,strengthen by steel tape with 3*6 or loose packing in containers |

loading quantity | 21.5CBM per 20'container |

minimum order quantity | one 20'container |

usage | used for furniture |

payment term | by T/T or L/C at sight |

delivery time | within 20 days after we got your advance payment |

2. Packing Details of Melamine Faced MDF Boards

Four sides are around with MDF in thickness ≥4mm,

Top cover is thin MDF in thickness ≥ 8mm,

Bottom board is MDF in thickness ≥12mm ,

4+8 steel strips.

3. Surface Texture of Melamine Faced MDF Boards

Satin, Pearl, Wood Grain, Corrugation. Here we have the picture for your referenc

FAQ

A. how many sheets for one cubic meter?

Answer:

6mm---56 sheets/CBM

9mm---37.33 sheets/CBM

12mm---28 sheets/CBM

15mm---22.40 sheets/CBM

18mm---18.66 sheets/CBM

21mm---16.00 sheets/CBM

B. how many cubic can load for one container?

Answer:

20FT---21.4 cbm 40ft---37 cbm

- Q:What kind of sheet is the board of the billet board?

- Veneer, also known as veneer, panel, dough. It is a wood flake material produced by a peeling or sawing method. Its thickness is usually between 0.4-1.0mm, mainly for the production of plywood and other plywood.

- Q:How to choose tiles

- Third, the drip test. Can be the water droplets in the back of the tile, watching the water spread after the infiltration of the speed, in general, the slower the water, indicating that the greater the density of the tile; the other hand, the faster water, indicating the density of sparse, the inherent quality of the former is excellent.

- Q:Wall shape plywood with light bulb how much appropriate

- 10cm is enough on the one hand you have to look good to see too little slightly stingy too much easy to see inside the lamp

- Q:What are the shortcomings and advantages of oak plywood?

- Oak furniture Disadvantages 2: oak furniture is relatively easy and rubber wood furniture confused, will affect the consumer's judgment. In the domestic oak furniture, although all aspects of the process are very good, but the general oak furniture is not a good maintenance, then after a year or so may be the old contraction.

- Q:Is the wooden door good for solid wood or plywood?

- Natural environmental protection, which is the biggest feature of solid wood furniture. Compared with those wood-based panels, the amount of glue is relatively small. The amount of plastic with the impact of the environmental impact of the level of furniture.

- Q:The difference between eco-board and blockboard

- Fuqing ecological board main: used in furniture, wooden doors and indoor and outdoor decoration, do not need to use lacquer blockboard: the general use with the plywood, for home decoration in the wall, the top decoration

- Q:What is the thickness of the trim panel?

- Decorative panel specifications commonly used 2440mm * 1220mm, 1000mm * 2000mm, 1220mm * 2000mm, 1200mm * 3000mm.

- Q:How to identify the furniture board is good or bad

- Method 2: see if there is no place to plywood, you can look at the wood, and now the market is mostly selling the MDF, particleboard, solid wood three categories. Density board points high density, medium density, resolution method, look inside the delicate degree of wood fiber (no miscellaneous wood slag).

- Q:What is the paper for pvc plywood?

- San alfloxacin is a kind of glue 3, containing a quantitative formaldehyde, formal plant p home in the process of gluing 5, formaldehyde can be 2 in the national standard range 6

- Q:Millennium boat plate is good, want to buy but do not know how?

- Store is selling OEM, very bad, there are smell, find a practical look to understand!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

18mm Both Sides Melamine MDF for Furniture or Decoration

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 200000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords