15m³ Concrete truck mixer / ISO & CE certificate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 PCS

- Supply Capability:

- 8 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

15m³ Concrete truck mixer / ISO & CE certificate

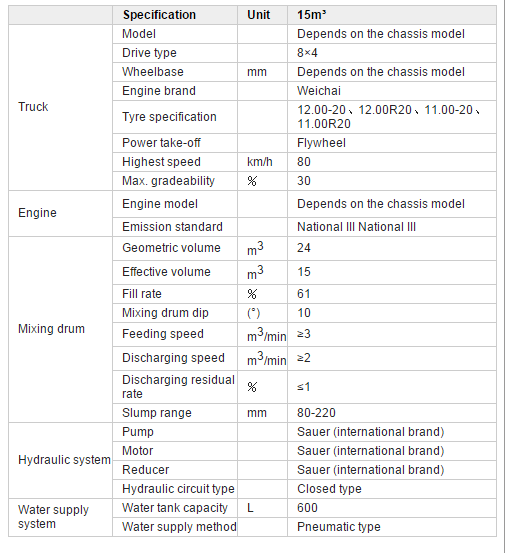

Specification

Hydraulic system

•The split hydraulic system features low cost and easy maintenance;

•The best hydraulic system assembly in the world.

•The company has good relationship with leading hydraulic system manufacturers. The hydraulic system is the most reliable, featuring compact structure and easy maintenance.

•The hydraulic pump suspension frame adopts U type bolt fixing, featuring good interchangeability and easy maintenance; It adopts Sauer hydraulic oil pump, motor and reducer.

Water supply system

•Large water tank capacity; One-time water using cycle is long;

•Pneumatic type water supply; Washing system, high water supply pressure, clean the feeding hopper and, discharging slot, tank and other equipment;

•One switch on the bottom of the cleaning system, which can discharge the water completely in winter.

•The water pump and shower nozzle are arranged reasonably, which are easy to operate.

Operation system

•It adopts the control method of mechanical linkage, and optimize the traditional operation structure, which is easier and more reliable for the operator.

•The cab adds the internal operation handle, which is easy for operation without getting off.

•Control the mixing and discharging speed by the throttle, and load (acceleration) and unload (acceleration) the material.

•Optimize the operation reliability, and eliminate the safety loophole.

Feeding and discharging system

•Add the quick coupler for watering, and the optimized hopper is easy to feed and discharge the concrete;

•The feeding height of less than 3850mm is suitable for the mixer, and the upper of feeding hopper is less than 650mm;

•The discharging height of 1350mm-1550mm is suitable for the feeding inlet of the pump;

Upper electrical system

•The electrical system is in single line, with negative pole on iron. The line voltage is 24V.

•The electrical system consists of illuminator, hydraulic oil temperature control switch, relay, and fan motor. When the oil temperature is over 60°C, the temperature control switch will connect and the cooling fan will rotate; when the oil temperature is below 55°C, the temperature control switch will disconnect and the cooling fan will stop.

•The work lamp switch controls the work lamp.

- Q:What is the driving license for a concrete mixer truck?

- Fees vary from anywhere from 2,500 to 3,500 Some places can be around 4,000 to 4500 The other thing is to get a certification, but the car on the site is generally unexamined.

- Q:What is the meaning of the word "concrete" in the concrete mixer jar?

- "Concrete" is a synonym for "concrete". Everyone knows that, especially gay people who work in the construction of the gay community, probably know the word. But who created the concrete? When was it approved for general purpose? -- I'm afraid not! The creator of the word "concrete" is professor CAI fangyin, a prominent structural scientist. The creation time is 1953! 56 years to date. The teaching technology was backward, there was no tape recorder, no copiers... Students take notes in class. "Concrete" is the most commonly used word in construction projects, but there are too many strokes to write. Hence the thinking agile CAI fang Yin is bold to use "artificial stone" 3 words instead "concrete". Because "concrete" three words have 30 words, and "artificial stone" three words only ten, can save 20 pen, greatly speed up the note speed! Then "artificial stone" synthesized "concrete"! And they are promoted in college students. Published in July 1955, the compilation of the Chinese academy of sciences committee room "noun" examination and issued "structural engineering noun", explicitly recommend "concrete" and the word "concrete" and use. Since then, "concrete" has been widely used in the books and periodicals of various kinds of construction projects. On June 7, 1985, the Chinese language reform commission formally approved the "concrete" and "concrete" synonym and the legal status of the "concrete". In addition, the sound of the "concrete", tong (the same), happens to BE "bee-ton" in French. German "be-ton", Russian "Be - TOH

- Q:Does it affect the ease of mixing too long?

- First, the quality is stable and controllable Second, there is less pollution of the environment Three, the energy conservation The mixer is required for both shipping distance and mixing speed, a bit technical

- Q:How many layers of steel wire tyres are used in concrete mixers

- For example; 1200 the r20 pr M588 18 1200 is the outer circle size R is the radial tire 20 is the inner circle size, Should be 18PR!!!!!! This is the level of the wire in the tyre. M588 is the symbol of tire tire!! Concrete agitator truck tyres are usually used in 18 levels of steel wire tyres, which is used in 20 levels I'm selling tyres, I hope to help you

- Q:How did the concrete agitate the concrete

- When pouring into the mixing building, the two sides of the car are equal to the stirring bracket, and the first time the mouth is made a mark, so that the next time it will be successful!

- Q:How many cubic meters of concrete mixer transport vehicle

- Dongfeng 140 concrete mixer truck, dongfeng 145 concrete mixer truck, dongfeng 153 concrete mixer truck, dongfeng hercules concrete mixer truck, dongfeng tianlong build concrete mixer truck concrete mixers, liberation, steyr, concrete mixer truck concrete mixer truck, hongyan, Europe man special concrete mixer truck concrete mixers and other projects.

- Q:s the collapse of four concrete mixer trucks

- The caving degree is 4 cannot be transported by concrete mixer, the slump is put into and out of the tank car. The average slump is 100 to 120mm, and it is better not to transport the concrete transporter, preferably with a construction dump truck.

- Q:Is it possible to mix the concrete in a mixing truck for eight hours?

- I think the main thing is to look at the state, but now the concrete is usually required to be discharged within four hours after the discharge (guangdong area).

- Q:What is the purpose of the concrete mixer

- The main purpose of the mixer is to transport concrete or slurry that is already in a concrete mixer to the construction site. Due to concrete truck mixer mixing tank is adjustable speed rotating stirring, so the concrete mixer truck transport can maximum guarantee stipulated in the delivery distance and time not segregation, coarse aggregate is not settling, maintain good workability; Mixed soil mixer is used for the construction of hybrid stations and large projects. Another concrete mixer is used for carrying water that can carry the same amount of concrete as the payload.

- Q:How does the concrete mixing truck work?

- Operating mechanism (1) control the rotating direction of the mixing cylinder so that it is rotating in the process of feeding and transportation. (2) control the speed of the mixer. The mixing device consists mainly of the mixer and its auxiliary supporting parts. Mixing drum of concrete loaded containers, rotates the concrete along the blade spiral direction, constantly in the process of ascension and turning by mixing and stirring. In the process of feeding and transportation, the mixing cylinder is turning, the concrete is moving in the blade, and the mixing cylinder is turned and the concrete is removed out of the blade. The blades are the main parts of the mixing plant, and the damage or severe wear and tear can cause the concrete to be mixed. In addition, if the design is unreasonable, the concrete will be isolated

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

15m³ Concrete truck mixer / ISO & CE certificate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 PCS

- Supply Capability:

- 8 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords