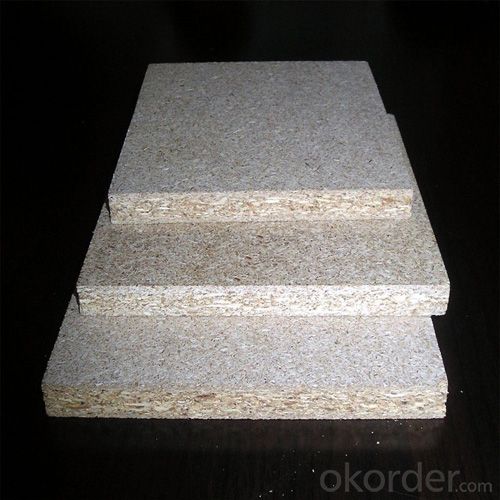

15 mm Thickness Chipboard with High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

· Type: Fibreboards

· Place of Origin: Shandong, China (Mainland)

· Material: Wood Fiber

· Usage: Indoor

· Grade: First-Class, First-Class

· Fibreboard Type: Low Density Fibreboards / Softboards

· Formaldehyde Emission Standards: E2

· Density: 600kgs/m3

· Veneer: raw or melamine paper

· Thickness tolerance: ±0.2mm

· Core: poplar

Packaging & Delivery:

Packaging Details: | Standard export packing. Each bundle will be protected with plastic membrane to seal well, using protect-board for the top and the bottom, the thickness should not less than 4mm for top, and not less than 10mm for bottom |

Delivery Detail: | 15 days after getting your 30% deposit |

Specifications:

Best price chipboard 15mm :

1.Size: 1220X2440mm

2.Thickness: 12/15/16/18/22/25/27mm

3.Glue: E2

4.Certificate:CARB ISO9001 IS

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q:Wenzhou Caigang tile and sandwich panels, steel processing costs is how much

- Color steel tile processing 12 yuan package contractor price 70-90 Stainless steel staircase handrail 60-90 steel 80-180 Unit: per square

- Q:With a foam sandwich board made a 72 flat house, the cheapest how much money

- It depends on how high your house, the color plate is calculated by the board area, calculate the material about 90 or so per square

- Q:Sandwich panel wall design please help?

- If it is to order the plate of this algorithm to die

- Q:Does the country 's steel market have sandwich panels?

- Sandwich panel products are composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the composition of the polymer core insulation. These sandwich panels are easy to install, lightweight and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor. The forming of the outer steel sheet takes into account the structural and strength requirements, and takes into account the appearance, the inner layer is formed into a flat plate to suit various needs. Guoqiang steel market with sandwich panels.

- Q:Have to know the holy spring Antwerp phenolic steel sandwich board how much money a square? I heard that the insulation effect is good, fire performance is also very good

- Phenolic insulation board a square 400 or so it Almost all of the price of phenolic need 50 points of oxygen was on fire, OKorder Zhongji machinery manufacturing phenolic insulation is the export, to the domestic sales a little less, you can order the next.

- Q:How to choose the type of steel structure plant roof sandwich panels

- According to the functional requirements of Party A or plant to choose the type of roof sandwich panels, such as you want to set fire, then generally use rock wool; insulation, then with the composite board, as is the general insulation or important insulation (for cold storage) According to his weight. As for the upper and lower board general Party has a request, if the party did not ask, it is like a routine

- Q:Level sandwich panels are not 820 type

- In fact this is nothing, JXB is not the first letter of the word sandwich panels. 42-333-1000 This is the sandwich panel on the upper and lower color plate model. For example: YX28-205-820 pressure wave height of 28MM wave width 205MM effective width is 820mm a look at this model is 4 wave color plate JXB42-333-1000 can explain: sandwich board which up and down a plate of the color plate 42MM pitch 333 effective use of the width of 1000 This model can be seen is 3 wave pressure plate. Sandwich panels are made of upper and lower color plate glue (foam) combination. The composition of the bubble is different, the name is also different, there are rock wool with polyurethane and so on

- Q:What is the difference between a simple room sandwich panel and a steel plate?

- Sandwich panels are two color steel plate sandwich material, usually folder foam or rock wool, insulation, insulation, sound insulation effect.

- Q:The current market price is how much money a square meter?

- Color plate, foam core, safe, durable, beautiful. Shelf life of more than 10 years. Color steel plate prices to see the thickness of the GB of 02,0.4,0.6,0.8, non-GB of the more, 0.3,0.5,0.35,0.45 have, you'd better ask the price in the local, around the price of different ah, Plus the freight of what, it is difficult to cost.

- Q:Sandwich board glue where the good

- There are too many types of glue can not be unified If it is on the market of ordinary glue, its composition is basically water, add some polyvinyl alcohol, white latex, sodium stearate, talc, urea, ethylene glycol, sucrose, flavor, etc., little harm to the human body (if Used to eat), if used when the eye drops with the estimated consequences are more serious. 502 glue is the main component of α-cyanoacrylate, its essence is colorless and transparent, low viscosity, non-combustible liquid, a single component, no solvent, slightly stimulating taste, volatile, volatile gas with weak tear The Building adhesive, 707 emulsion and other high-level additives, the current commonly used 108 plastic main component of polyvinyl alcohol Scope This product is suitable for concrete, aerated concrete, lime sand brick, fly ash brick interface treatment, can also be used for plastering mortar, paste the tile sand ash additives to enhance the adhesive force.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

15 mm Thickness Chipboard with High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords