1220*2440 Film Faced Plywood Brown O Black

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

DESCRIPTION:

| Type: | Plywoods | Place of Origin: | Shandong, China (Mainland) | Brand Name: | bailing |

| Model Number: | BL07142 | Usage: | Outdoor | Grade: | First-Class |

| Main Material: | Poplar | Formaldehyde Emission Standards: | E1 | Plywood Type: | 13-Ply Boards |

| grad: | AAA/AA | glue: | MR,WBP | face/back: | black,brown |

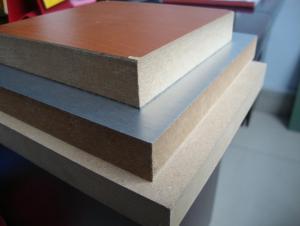

| size: | 1220*2440mm | thickness: | 12mm,15mm,18mm,21mm | core: | poplar,hardwood,birch,combin |

specification:

Size | 1220*2440mm,1250*2500mm or as requested |

Thickness | 2.5-25mm |

Core | poplar, combi, hardwood |

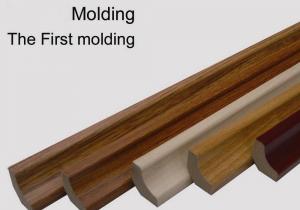

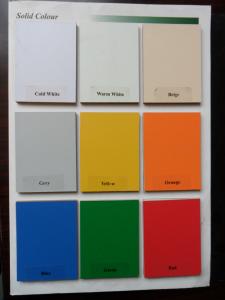

Film | chinese brown, dynea brown, black, red |

Glue | MR, WBP, melamine |

Density | 500-630kgs/cbm |

Moisture | 6-14% |

Thickness tolerance | +/-0.5mm |

Modulus of rupture | ≥30Mpa |

Modulus of Elasticity | ≥6000Mpa |

Packing | inside by 0.2mm plastic bag, outside by carton box and bundled by steel strip |

Delivery | within 15 days after receiving the deposit |

FEATURE:

1. We have 20 years of experience in export board.

2. We are professional in the manufacturing wood board.

3. We can offer you competitive price with lowest cost but good quality.

PICTURES:

- Q:What kind of sheet is the board of the billet board?

- General quality veneer for plywood, blockboard, stencils, panels and other panels of wood-based panels, lower grade veneer used as a backplane and core board.

- Q:What is teak finish?

- See the thickness of the panel, the thicker the better the performance, the more realistic wood after the paint, the more clear texture, bright color saturation is good. How to identify the thickness of the panel? Kanban edge of the sand or not, the board with or without glue, coated with water experiments to see whether the green. Penetration phenomenon, if there is such a problem, it belongs to the panel skin thin.

- Q:What are the shortcomings and advantages of oak plywood?

- Oak furniture Disadvantages 2: oak furniture is relatively easy and rubber wood furniture confused, will affect the consumer's judgment. In the domestic oak furniture, although all aspects of the process are very good, but the general oak furniture is not a good maintenance, then after a year or so may be the old contraction.

- Q:What are the advantages and disadvantages of decorative panels?

- Melamine plywood can be imitation of a variety of patterns, bright color, for a variety of wood-based panels and wood veneer, hardness, wear resistance, heat resistance. Melamine plywood resistant to chemical properties, and can resist the general acid , Alkali, grease and alcohol and other solvents. Melamine plywood surface smooth and smooth, easy maintenance and cleaning .As melamine plywood with natural wood can not have both the excellent performance, it is often used for indoor construction and furniture, Melamine plywood surface smooth and smooth, easy to maintain cleaning

- Q:Melamine plywood (do board with the board) dirty how to clean

- Rub with the detergent powder, or with the decontamination powder, this thing out of the factory when the water is used to wipe the water

- Q:Double-sided eco-board with what adhesive stickers

- The key in the ecological word, is the human gimmick, ecology, what is the ecological, the same thing, not the same name. Only.

- Q:What is the thickness of the trim panel?

- Decorative panel specifications are a piece of wood made of wood or natural wood sliced, adhere to the plywood surface material.

- Q:Melamine plywood and fire board panels which is good? That environmental protection?

- As for what you say environmental protection, in fact, both have melamine ingredients, but the fire board compared to deal with better, it is recommended to use fire board

- Q:What is the difference between solid wood veneer doors and solid wood composite doors?

- Paint inside the door as long as the brand inside the door are solid wood, the price is more expensive, the outside pressure is the high density board less than 6 mm, the density board is better, on the outside of the tree is the skin of the general door are 3 thick, brand doors are at least six thick, the difference lies in the material, and processing technology, technology is not reached, then also white pull

- Q:Will the fire board be used as a plywood for furniture?

- We specialize in exporting, many of the foreign furniture is required to produce fire board panels.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1220*2440 Film Faced Plywood Brown O Black

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords