120 Type Steel Frame Formwork for Column Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of 120 Steel frame formwork-column formwork

With adjustable flexiable sizes of frame, the column steel formwork is a heavy-bearing steel frame formwork works with steel frame, plywood and lock. It is widely used in various projects and reduce cost by using standardized sizes of forms as well. The concrete surface is quite clean with column formwork. As the framework, it is adapted to the plywood with thickness of 18mm. High-precision production line guarantees the perfect products.

2. Main Features of 120 Steel frame formwork-Column formwork

◆ Allowable pressure is 80KN/m2 .

◆ Faster and easy operation.

◆ The dimension for column is adjustable.

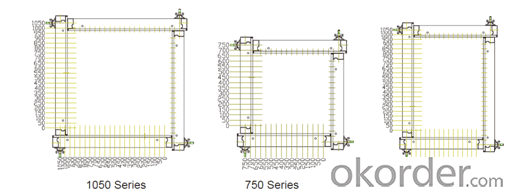

3. 120 Steel frame formwork-column formwork Images

4. 120 Steel frame formwork-Column Formwork Specifications

1050 Series /750 Series Adjustable Column Formwork

5. FAQ of 120 Steel frame formwork-column formwork

1) What can we do for you?

.We can ensure the quality of the120 Steel frame formwork-column formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. If interested in this kind of early prop head formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q:Can steel frame formwork be used for architectural concrete structures?

- Yes, steel frame formwork can be used for architectural concrete structures. Steel frame formwork is a versatile and durable option that offers several advantages for architectural concrete construction. One of the key benefits of steel frame formwork is its strength and stability. Steel is a strong material that can withstand the pressure exerted by fresh concrete during the pouring and curing process. This allows for the construction of complex architectural concrete structures that require intricate designs and shapes. Additionally, steel frame formwork provides excellent dimensional accuracy, ensuring that the final concrete structure meets the architectural specifications. The steel frames are designed to be easily adjustable, allowing for precise control over the formwork dimensions and ensuring a high level of accuracy in the finished product. Moreover, steel frame formwork is reusable, making it a cost-effective option for architectural concrete construction. The frames can be easily dismantled and reassembled for use in future projects, reducing the need for new formwork materials and minimizing waste. Furthermore, steel frame formwork offers flexibility in terms of customization. The frames can be fabricated to match the specific architectural requirements, allowing for the creation of unique and visually appealing concrete structures. This makes steel frame formwork an ideal choice for architectural projects where aesthetics are a major consideration. In conclusion, steel frame formwork can indeed be used for architectural concrete structures. Its strength, stability, dimensional accuracy, reusability, and customization options make it a reliable and efficient choice for creating visually stunning architectural concrete designs.

- Q:Can steel frame formwork be used in areas with high humidity levels?

- Yes, steel frame formwork can be used in areas with high humidity levels. Steel is a highly durable and corrosion-resistant material, making it ideal for use in humid environments. Additionally, steel formwork can be coated with protective coatings or rust inhibitors to further enhance its resistance to moisture. This makes it suitable for construction projects in coastal areas, tropical regions, or any other areas with high humidity levels. However, it is important to ensure proper maintenance and regular inspections to prevent any potential corrosion or damage to the steel frame formwork.

- Q:Can steel frame formwork be used for both residential and commercial construction?

- Steel frame formwork is a valuable choice for both residential and commercial construction. This versatile and enduring solution is suitable for a range of construction projects, including residential and commercial buildings. It possesses remarkable strength and stability, enabling it to withstand the pressure and weight of concrete during pouring and curing. Moreover, steel frame formwork is both adjustable and reusable, offering a cost-effective option for small-scale residential projects and large-scale commercial developments alike. Its adaptability allows for the construction of diverse shapes and sizes, meeting the demands of various architectural designs. In summary, steel frame formwork is a dependable choice for both residential and commercial construction ventures.

- Q:What are the environmental certifications required for steel frame formwork?

- There are several environmental certifications that may be required for steel frame formwork. Some common ones include the Forest Stewardship Council (FSC) certification, which ensures that the wood used in the formwork comes from responsibly managed forests. Additionally, certifications such as ISO 14001 and LEED (Leadership in Energy and Environmental Design) can also be relevant in demonstrating the environmental sustainability of the steel frame formwork.

- Q:How do you ensure the quality of steel frame formwork?

- To guarantee the structural integrity and safety of buildings, it is crucial to prioritize the quality of steel frame formwork in construction projects. There are several effective methods and practices that can be employed to achieve this: 1. Procure materials from reputable suppliers: It is essential to source steel frame formwork materials from trusted suppliers who adhere to stringent quality control standards and possess relevant certifications. This ensures that the materials used meet the required specifications and have undergone thorough testing. 2. Conduct regular inspections: Regular inspections should be conducted throughout the manufacturing process to identify any manufacturing defects or inconsistencies. This includes examining the welds, joints, and overall construction of the formwork. 3. Perform quality tests: Various quality tests should be carried out on the steel frame formwork to verify its strength, durability, and performance. These tests may encompass load testing, bending tests, and material composition analysis. By conducting these tests, any potential weaknesses or defects can be detected and rectified before the formwork is utilized on-site. 4. Adhere to industry standards and guidelines: It is imperative to comply with industry standards and guidelines, such as those established by the International Organization for Standardization (ISO) or local regulatory bodies. These standards provide a framework for ensuring quality assurance and guaranteeing that the formwork meets the required specifications. 5. Ensure proper storage and handling: Steel frame formwork should be stored in a dry and protected environment to prevent corrosion and damage. It is crucial to follow appropriate handling techniques to avoid any bending or distortion of the formwork components. 6. Regularly maintain and repair: Regular inspections and maintenance should be conducted to preserve the structural integrity of the steel frame formwork. Any signs of wear, damage, or rust should be promptly addressed through repairs or replacements of the affected components. 7. Provide training and supervision: Adequate training should be provided to construction workers responsible for assembling and using the steel frame formwork. Regular supervision should be carried out to ensure the correct utilization of the formwork and prompt resolution of any potential issues. By implementing these measures, construction professionals can ensure the high quality of steel frame formwork, resulting in safer and more reliable construction projects.

- Q:What are the different types of form stripping methods used with steel frame formwork?

- There are several different types of form stripping methods used with steel frame formwork, each with its own advantages and considerations. 1. Crane lifting: This method involves using a crane to lift the formwork panels and move them away from the concrete structure once the concrete has cured. It is a common method for large-scale projects where there is ample space for the crane to maneuver. 2. Forklift stripping: Forklift stripping is similar to crane lifting, but instead of using a crane, a forklift is used to lift and remove the formwork panels. This method is suitable for smaller projects or areas where a crane may not have access. 3. Stripping with hydraulic systems: Hydraulic systems can be used to strip the formwork by applying pressure to release the formwork panels from the concrete structure. This method is popular for its efficiency and ease of use, especially in projects with limited space or access. 4. Stripping with mechanical systems: Mechanical systems involve the use of mechanical devices, such as jacks or hooks, to remove the formwork panels. This method allows for controlled and precise stripping, making it suitable for projects with complex shapes or intricate details. 5. Manual stripping: Manual stripping is the most basic and labor-intensive method, where workers manually remove the formwork panels using hand tools. While this method may be time-consuming, it is cost-effective and suitable for smaller projects or areas where mechanical or hydraulic systems may not be feasible. It is important to note that the choice of form stripping method depends on various factors, including the project size, complexity, available resources, and time constraints. Contractors and engineers need to consider these factors when deciding on the most appropriate method to ensure efficient and safe formwork removal.

- Q:Can steel frame formwork be used for both heavy and lightweight concrete structures?

- Yes, steel frame formwork can be used for both heavy and lightweight concrete structures. Steel frame formwork is a versatile and durable solution that can accommodate different types of concrete structures. It provides the necessary support and stability during the pouring and curing process, regardless of the weight of the concrete. The strength and rigidity of steel make it suitable for heavy concrete structures, while its flexibility and adaptability allow it to be used for lightweight concrete structures as well. Additionally, steel frame formwork can be easily adjusted and reused, making it a cost-effective option for various construction projects.

- Q:What are the different types of coatings or surface treatments applied to steel frame formwork?

- To enhance the performance and durability of steel frame formwork, there are various coatings and surface treatments available. These include: 1. Galvanized Coating: By utilizing hot-dip galvanizing, a layer of zinc is applied to the steel surface. This coating effectively protects the formwork from rust and other environmental damages, ensuring excellent corrosion resistance. 2. Powder Coating: This popular method involves the application of a dry powder to the steel surface, followed by heating to form a protective layer. The resulting coating provides durability, safeguarding the formwork against scratches, chemicals, and UV rays. 3. Epoxy Coating: In aggressive environments where corrosion resistance is vital, epoxy coatings are commonly used. Applied in multiple layers, these coatings offer exceptional chemical resistance, protecting the formwork from acids, alkalis, and other corrosive substances. 4. Paint Coating: Paint coatings are frequently chosen for steel formwork as they provide decorative finishes while offering some degree of corrosion protection. However, regular maintenance may be necessary, and these coatings may not be as durable as other options. 5. Zinc-Rich Primer: Prior to the final coating, zinc-rich primers are applied as a base coat to provide additional corrosion protection. These primers, containing substantial levels of zinc, act as sacrificial anodes to prevent steel corrosion. 6. Anodized Coating: Initially developed for aluminum formwork, anodizing can also be applied to steel. This process involves the creation of an aluminum oxide layer on the surface through electrochemical means. The resulting coating enhances corrosion resistance and improves the formwork's appearance. When selecting the appropriate coating or surface treatment for steel frame formwork, it is crucial to consider factors such as the specific application, environmental conditions, and desired level of protection. Corrosion resistance, durability, aesthetics, and maintenance requirements should all be taken into account to make an informed decision.

- Q:Are there any restrictions on the formwork height that can be achieved with steel frame formwork?

- Yes, there are restrictions on the formwork height that can be achieved with steel frame formwork. The maximum height is determined by factors such as the structural strength of the formwork system, the weight and pressure exerted by the concrete, and the stability of the structure during the pouring and curing process. It is important to adhere to the manufacturer's guidelines and engineering specifications to ensure the safe and effective use of steel frame formwork for varying heights.

- Q:What are the different types of form release agents used with steel frame formwork?

- There are primarily two types of form release agents used with steel frame formwork: barrier release agents and chemically reactive release agents. Barrier release agents create a physical barrier between the formwork and the concrete, preventing adhesion. Chemically reactive release agents chemically react with the concrete, forming a slippery film that allows for easy release.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

120 Type Steel Frame Formwork for Column Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords