100% Water Soluble Sewing Thread Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

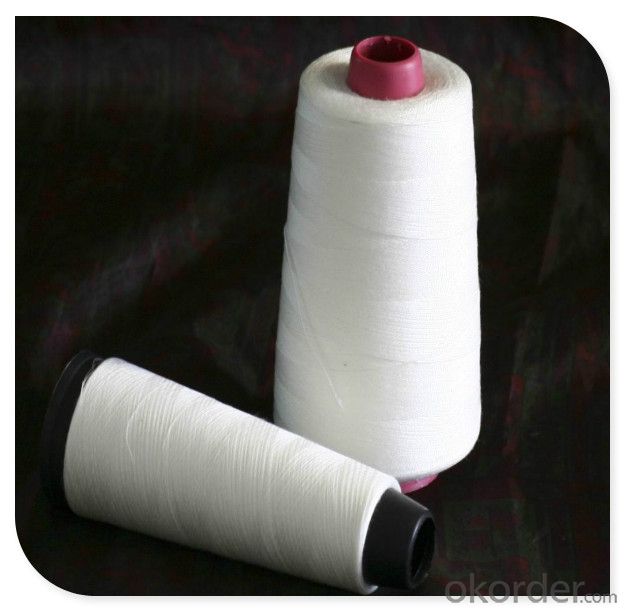

100% Water Soluble Sewing Thread Made in China

Brife introduce:

Water-solubel PVA yarn

1) reasonable price

2) high quality

3) customized

5) payment: T/Tor L/C

Specs:

| Product name | 100 PVA yarn |

| Material | 100% whalen |

| Yarn type | spun yarn |

| Pattern | raw white |

| Style | ring spun yarn |

| Techniques | ring spun, siro spun or siro compact spun |

| Feature | Eco-Friendly, heat resistance, alkali-resistance, Moisture-Absorbent, |

| Use | Knitting, Weaving |

| payment | 100%TT T/T 30 in prepayment and the balance should be paid upon the copy of B/L, L/C at sight |

| Twistness | bellow 330 for knitting, above 380 for weaving |

| Yarn count | 20S-70S and 2-ply |

| package | 1, usually pp bags packing, 25kgs per bag , 320 bags /one 20'container (8tons) 2, also supply carton packing, 40kgs per carton, 150 carton / one 20' container (6tons) 3, also pallet packing 4, according to customers'needs |

We can supply water soluble yarn, 20 degree to 90 degree, yarn counts are from 20s to 100s.

This is a new kind of environmental friendly product. It can be mainly used for making towels,socks, the top-grade gloves, etc.

It can be used to make the untwist yarn with the cotton yarn.

We are the manufacture, we export the pva yarns to India, Turkey, Pakistan,etc. Have a large market, If you have any requirment, please feel free to contact us.

PVA yarn: 20/40/70/80/90 degree

Ne 20s/1 40s/1 50s/1 60s/1 80s/1 100s/1

hot water soluble yarn use the China Sinopec pva fiber .

Cold water soluble yarn use the Japan pva fiber .

Sample delivery:

- Q:On the number of textile yarns

- Simply said that the length of the unit weight, the longer the length will be fine, so the greater the number of yarn the more thin!

- Q:What is the reason why the yarn is spinning

- The insurance yarn is woven out of cloth on the edge of 0.5 to 1 cm of the lock side, is to prevent the yarn spread out the yarn, the insurance yarn is more important than the weaving yarn

- Q:What is the reason for the low strength of cotton yarn

- We found in the spinning frame yarn problems, roving weight qualified, and later found in the apron with a plot of flowers, may affect the yarn less stretch.

- Q:What is yarn support?

- Metric count (Nm) - At a given moisture regain, 1 gram of yarn length is a meter multiple, that is, 1 gram of heavy yarn is just 1 meter long, 1 (g) yarn, 1 gram heavy yarn Length of 200 meters long, the fineness of the yarn 200

- Q:What are the types of cotton yarns?

- (Also known as S twist) yarn, used to weave the weft of the weft yarn (2) according to twist to the point: ① backhand twist (also known as Z twist) yarn, in a variety of fabrics in the most widely used;

- Q:From the yarn to the finished textile fabric production process

- Nylon is the most important engineering plastics, production in the top five general engineering plastics in the first place. Nylon [1], is a polyamide fiber (nylon) is a saying can be made of long fiber or staple fiber. Mercerized cotton: in accordance with the two mercerizing process division, mercerized cotton can refer to the yarn through the mercerized process of cotton yarn, but also through the fabric mercerized cotton fabric. Yarn mercerizing: refers to the cotton yarn in the case of tension, after the treatment of concentrated caustic soda, so that it has both the original characteristics of cotton, but also has a silk general luster of a special type of cotton yarn.

- Q:Textile exports to South Korea need to do what certification, pure cotton yarn

- Customs declaration can be reported at the same time multiple names, if the same in a single check on a single name, provided that these kinds of goods are the same factory production.

- Q:Cotton cotton yarn consumption of cotton how much?

- Cotton combed cotton consumption quota: 1.3 tons / ton yarn; yarn per ton of finished yarn 0.77 tons. Polyester cotton carded cotton (cotton 35% polyester 65%) cotton consumption quota: 0.45 tons / ton yarn; (polyester 0.67 tons / ton yarn).

- Q:How does textile twist yarn identify?

- Observe the fiber near the flame, contact with the flame, leaving the flame produced by a variety of different phenomena and the combustion of the odor, the post-combustion residue to identify the fiber type.

- Q:What is the number of yarns used in cotton textiles to mean what is meant

- Fiber only after the textile can become a fabric, and the first step is spinning yarn.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

100% Water Soluble Sewing Thread Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords