All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How is aluminum coil production affected by market demand?

Aluminum coil production is directly influenced by market demand. When there is a high demand for aluminum products, such as in the construction or automotive industries, the production of aluminum coils increases to meet the market's needs. Conversely, when there is a decrease in demand, production may slow down or be adjusted accordingly to prevent excess inventory. The market demand plays a significant role in determining the production levels and overall supply of aluminum coils.

What are the benefits of pre-painted aluminum coils?

Pre-painted aluminum coils offer several benefits including enhanced durability, resistance to corrosion, reduced maintenance requirements, and a wide range of color options. They provide a protective coating that increases the lifespan of the aluminum, making it suitable for outdoor applications. The pre-painted finish also adds aesthetic appeal and can be customized to match specific design requirements. Additionally, the pre-painting process reduces the need for regular repainting, saving time and money in the long run.

How do you ensure the uniformity of coating thickness on aluminum coils for aesthetic purposes?

To ensure uniformity of coating thickness on aluminum coils for aesthetic purposes, several steps can be taken. First, it is crucial to establish and maintain a consistent and controlled coating application process. This involves using advanced coating techniques such as spray or dip coating, ensuring proper equipment calibration, and utilizing automated systems to control the coating parameters precisely. Additionally, implementing regular quality control checks at various stages of the coating process is essential. This includes conducting frequent measurements of coating thickness using appropriate instruments like thickness gauges and monitoring the coating application's speed and pressure. By adhering to stringent quality control measures and employing standardized coating procedures, the uniformity of the coating thickness on aluminum coils can be effectively ensured, resulting in a visually appealing and aesthetically consistent end product.

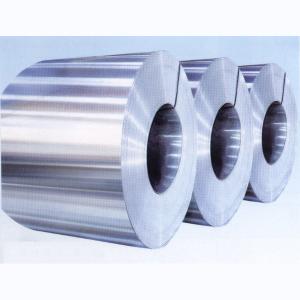

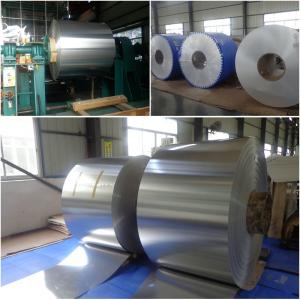

Wholesale Aluminum Coils from supplier in Uganda

We understand the importance of delivering high-quality products to our customers, which is why we source our Aluminum Coils from reliable manufacturers who adhere to strict quality standards. Our products undergo rigorous testing and inspection to ensure their durability, strength, and performance.

In addition to our top-quality products, we offer competitive pricing to help you optimize your costs and maximize your profitability. We understand the importance of staying competitive in the market, so we work closely with our suppliers to negotiate the best prices for our customers.

Furthermore, our technical support team is always ready to assist you with any questions or concerns you may have. We have a team of experienced professionals who can provide technical advice, recommend the most suitable products for your applications, and help you troubleshoot any issues that may arise.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This allows us to offer comprehensive procurement services, ensuring that you have a hassle-free and efficient procurement process. From product selection to delivery, we are committed to providing a seamless experience for our customers.

At our company, we prioritize customer satisfaction. We understand the importance of building long-term relationships with our clients, and we strive to exceed their expectations in every interaction. Our reliable supply chain ensures that you receive your Aluminum Coils on time and in perfect condition.

Whether you are looking for Aluminum Coils for construction, automotive, or any other industry, we have the right solution for you. Contact us today to discuss your requirements and let us be your trusted partner for all your Aluminum Coils needs in Uganda.

In addition to our top-quality products, we offer competitive pricing to help you optimize your costs and maximize your profitability. We understand the importance of staying competitive in the market, so we work closely with our suppliers to negotiate the best prices for our customers.

Furthermore, our technical support team is always ready to assist you with any questions or concerns you may have. We have a team of experienced professionals who can provide technical advice, recommend the most suitable products for your applications, and help you troubleshoot any issues that may arise.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This allows us to offer comprehensive procurement services, ensuring that you have a hassle-free and efficient procurement process. From product selection to delivery, we are committed to providing a seamless experience for our customers.

At our company, we prioritize customer satisfaction. We understand the importance of building long-term relationships with our clients, and we strive to exceed their expectations in every interaction. Our reliable supply chain ensures that you receive your Aluminum Coils on time and in perfect condition.

Whether you are looking for Aluminum Coils for construction, automotive, or any other industry, we have the right solution for you. Contact us today to discuss your requirements and let us be your trusted partner for all your Aluminum Coils needs in Uganda.