All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the average cost of hollow steel tubes per meter?

The average cost of hollow steel tubes per meter can vary depending on factors such as size, thickness, and market conditions. It is recommended to consult with suppliers or conduct market research to obtain the most accurate and up-to-date pricing information.

Are hollow steel tubes suitable for modular construction?

Yes, hollow steel tubes are highly suitable for modular construction. Their lightweight yet strong nature makes them ideal for constructing modular buildings, as they can be easily transported, assembled, and disassembled. Additionally, the hollow design allows for easy installation of electrical and plumbing systems, making them a popular choice in the modular construction industry.

Can hollow steel tubes be used for roller coasters?

Yes, hollow steel tubes can be used for roller coasters. In fact, they are commonly used in the construction of roller coasters due to their strength, durability, and ability to withstand high speeds and forces. The hollow design allows for a lighter structure without compromising on structural integrity, making them an ideal choice for creating thrilling and safe roller coaster rides.

What are the considerations for connecting hollow steel tubes to other materials?

When connecting hollow steel tubes to other materials, several considerations need to be taken into account. Firstly, the compatibility of the materials should be considered to ensure they can effectively bond or join together. This includes assessing factors such as their respective strengths, flexibility, and thermal expansion coefficients.

Secondly, the method of connection plays a crucial role. Different techniques, such as welding, bolting, or adhesive bonding, may be suitable depending on the application and desired strength of the joint. The chosen method should consider factors such as load-bearing capacity, durability, and ease of installation and maintenance.

Moreover, the design of the joint should be carefully considered to ensure proper load transfer and minimize stress concentrations. This involves determining the appropriate geometry, dimensions, and reinforcement techniques, such as using gussets or bracing, to enhance the overall structural integrity.

Another important consideration is the potential for corrosion. Steel tubes are susceptible to rust and corrosion, especially when connected to dissimilar materials. Thus, implementing corrosion protection measures, such as coatings, galvanization, or the use of compatible materials, is crucial to maintain the longevity and reliability of the connection.

Furthermore, environmental factors such as temperature variations, moisture, and chemical exposure should be taken into account. These factors can impact the performance and durability of the joint, necessitating appropriate material selection and protective measures.

Overall, the considerations for connecting hollow steel tubes to other materials revolve around material compatibility, connection method, joint design, corrosion protection, and environmental factors. Taking these factors into account ensures a strong, durable, and reliable connection.

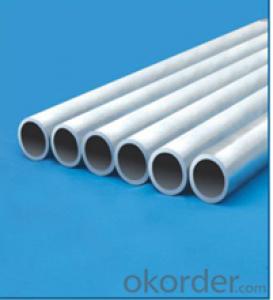

Wholesale Hollow Steel Tubes from supplier in Uganda

With our vast expertise and knowledge of the Ugandan market, we strive to meet the specific requirements of our clients in Uganda. We understand the importance of top-quality products in construction projects and aim to provide Hollow Steel Tubes that meet international standards.

Our team is dedicated to delivering exceptional customer service and technical support. We are committed to understanding the unique needs of each client and offering tailored solutions. Whether you require Hollow Steel Tubes for infrastructure development, industrial applications, or any other project, we have the expertise to assist you.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to a wide network of suppliers and resources. This enables us to offer comprehensive procurement solutions, ensuring a smooth and efficient supply chain for our clients in Uganda.

We take pride in our commitment to excellence and strive to exceed our clients' expectations. Our goal is to establish long-term relationships based on trust, reliability, and mutual success. When you choose us as your supplier of Hollow Steel Tubes in Uganda, you can be confident in receiving top-quality products, competitive prices, and unparalleled customer service.

Contact us today to discuss your requirements and let us be your trusted partner for Hollow Steel Tubes in Uganda.

Our team is dedicated to delivering exceptional customer service and technical support. We are committed to understanding the unique needs of each client and offering tailored solutions. Whether you require Hollow Steel Tubes for infrastructure development, industrial applications, or any other project, we have the expertise to assist you.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to a wide network of suppliers and resources. This enables us to offer comprehensive procurement solutions, ensuring a smooth and efficient supply chain for our clients in Uganda.

We take pride in our commitment to excellence and strive to exceed our clients' expectations. Our goal is to establish long-term relationships based on trust, reliability, and mutual success. When you choose us as your supplier of Hollow Steel Tubes in Uganda, you can be confident in receiving top-quality products, competitive prices, and unparalleled customer service.

Contact us today to discuss your requirements and let us be your trusted partner for Hollow Steel Tubes in Uganda.