All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

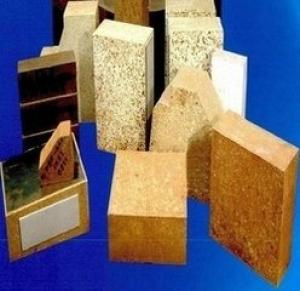

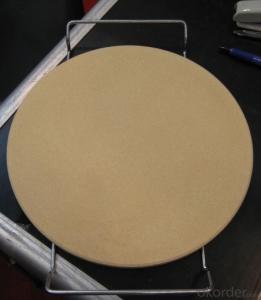

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

How do refractory materials withstand mechanical stress?

Refractory materials are designed to withstand mechanical stress due to their high melting points, strong chemical bonds, and dense structures. These properties allow them to maintain their shape and integrity even when exposed to high temperatures and physical forces. Additionally, some refractory materials contain additives or reinforcing fibers that enhance their strength and resistance to mechanical stress.

What are the challenges in using refractory materials in high-temperature applications?

One of the main challenges in using refractory materials in high-temperature applications is their ability to withstand extreme heat without undergoing significant structural or chemical changes. Refractories must have a high melting point and low thermal conductivity to prevent heat loss and maintain their integrity under intense heat conditions. Another challenge is their susceptibility to thermal shock, which can cause cracking or spalling when exposed to sudden temperature changes. Additionally, refractory materials may experience chemical reactions with the surrounding environment or undergo phase transformations at high temperatures, affecting their performance and durability. Overall, the selection and utilization of refractory materials for high-temperature applications require careful consideration of their thermal properties, stability, and resistance to various factors that can impact their performance.

What is the role of refractory materials in the energy sector?

Refractory materials play a crucial role in the energy sector by providing insulation and protection in high-temperature environments such as power plants and industrial furnaces. These materials help to minimize heat loss, improve energy efficiency, and ensure the durability and longevity of equipment and structures involved in energy production and storage processes.

How are refractory materials used in the foundry industry?

Refractory materials are used in the foundry industry to line furnaces, crucibles, and other high-temperature equipment, as they have the ability to withstand extreme heat without melting or deteriorating. These materials help to create a barrier between the molten metal and the surrounding environment, preventing contamination and ensuring the efficient and safe melting and casting of metals.

Wholesale Refractory Materials from supplier in Switzerland

Our goal is to be your reliable partner in the procurement of Refractory Materials, offering a seamless and efficient experience from start to finish. Whether you are working on a small-scale project or a large industrial undertaking, we have the capabilities to meet your needs.

In addition to our wide range of products, we also offer technical assistance to ensure that you select the right materials for your specific requirements. Our team of experts is available to provide guidance and support throughout the entire process, from product selection to installation.

At our company, quality is of utmost importance. We only work with trusted manufacturers who adhere to strict quality control measures, ensuring that the materials we supply meet the highest industry standards. This commitment to quality extends to our customer service, where we strive to exceed your expectations every step of the way.

With our extensive network and experience in the Swiss market, we are well-equipped to handle any challenges that may arise. We understand the unique requirements and regulations of the Swiss market, and our local presence allows us to provide prompt and efficient service.

When you choose us as your Refractory Materials supplier in Switzerland, you can be confident that you are receiving the best products, expert guidance, and exceptional service. We are dedicated to helping you achieve success in your projects and look forward to the opportunity to work with you.

In addition to our wide range of products, we also offer technical assistance to ensure that you select the right materials for your specific requirements. Our team of experts is available to provide guidance and support throughout the entire process, from product selection to installation.

At our company, quality is of utmost importance. We only work with trusted manufacturers who adhere to strict quality control measures, ensuring that the materials we supply meet the highest industry standards. This commitment to quality extends to our customer service, where we strive to exceed your expectations every step of the way.

With our extensive network and experience in the Swiss market, we are well-equipped to handle any challenges that may arise. We understand the unique requirements and regulations of the Swiss market, and our local presence allows us to provide prompt and efficient service.

When you choose us as your Refractory Materials supplier in Switzerland, you can be confident that you are receiving the best products, expert guidance, and exceptional service. We are dedicated to helping you achieve success in your projects and look forward to the opportunity to work with you.

Hot Search

- Monolithic Refractories in Bangladesh

- Ceramic Fiber Products in Palau

- Refractory Bricks in Mozambique

- Raw Materials For Refractory in Peru

- Refractory Bricks in Syria

- Ceramic Fiber Products in Thailand

- Monolithic Refractories in Iraq

- Refractory Bricks in Cyprus

- Refractory Bricks in Ghana

- Refractory Bricks in Barbados