All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

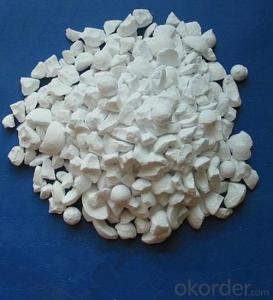

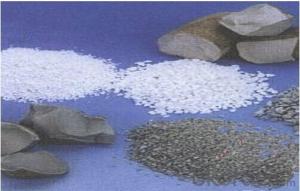

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How are calcium silicate boards employed in refractory linings and insulation?

Calcium silicate boards are commonly used in refractory linings and insulation due to their excellent thermal and fire-resistant properties. They are employed as a protective layer in furnaces, kilns, and other high-temperature applications to prevent heat loss and provide insulation. These boards are also known for their low thermal conductivity, which helps in maintaining consistent temperatures and reducing energy consumption. Additionally, calcium silicate boards are resistant to moisture and chemical corrosion, making them suitable for various industrial settings.

How does aluminum fluoride enhance the properties of refractory materials?

Aluminum fluoride enhances the properties of refractory materials by improving their thermal stability, increasing their resistance to corrosion, and enhancing their mechanical strength.

How do raw materials contribute to the resistance to slag penetration of refractory products?

Raw materials play a crucial role in determining the resistance to slag penetration of refractory products. The composition and quality of the raw materials used in the production of refractories greatly influence their performance and resistance to slag attack. Raw materials with high chemical and physical stability, such as high-purity minerals and refractory oxides, can enhance the resistance of refractory products to slag penetration. Additionally, the proper selection and combination of raw materials can create a dense and continuous matrix, making it difficult for slag to penetrate and corrode the refractory material.

How do different types of olivine compare in terms of performance in refractory applications?

Different types of olivine can vary in their performance in refractory applications. Generally, refractory olivine with higher levels of magnesium (Mg) tends to exhibit better thermal shock resistance and higher melting point, making it suitable for high-temperature applications. However, olivine with higher iron (Fe) content may offer better resistance against chemical attack. Ultimately, the choice of olivine for refractory applications depends on specific requirements such as temperature, chemical environment, and desired performance characteristics.

Wholesale Raw Materials For Refractory from supplier in Switzerland

Our team is dedicated to providing top-notch service and support for all your raw material needs in the refractory industry. We understand the specific requirements of our customers in Switzerland and strive to meet them with our extensive product range. With our expertise and knowledge of the Swiss market, we can offer valuable insights and advice to help you achieve success in your projects.

In addition to our focus on supplying raw materials, we also want to take this opportunity to highlight the beauty and attractions of Switzerland. From the stunning Swiss Alps to the picturesque lakes, Switzerland is a country that offers breathtaking landscapes and a high quality of life. It is also home to thriving industries, such as precision engineering, luxury watches, and pharmaceuticals. The country's rich cultural heritage and diverse traditions make it a vibrant and exciting place to visit.

Whether you are visiting Switzerland for business or leisure, we assure you that it will be an unforgettable experience. We invite you to explore all that Switzerland has to offer and to contact us for all your raw material needs in the refractory industry.

In addition to our focus on supplying raw materials, we also want to take this opportunity to highlight the beauty and attractions of Switzerland. From the stunning Swiss Alps to the picturesque lakes, Switzerland is a country that offers breathtaking landscapes and a high quality of life. It is also home to thriving industries, such as precision engineering, luxury watches, and pharmaceuticals. The country's rich cultural heritage and diverse traditions make it a vibrant and exciting place to visit.

Whether you are visiting Switzerland for business or leisure, we assure you that it will be an unforgettable experience. We invite you to explore all that Switzerland has to offer and to contact us for all your raw material needs in the refractory industry.

Hot Search

- Monolithic Refractories in Rwanda

- Ceramic Fiber Products in Bangladesh

- Refractory Bricks in Bahrain

- Raw Materials For Refractory in Kuwait

- Refractory Bricks in Turkmenistan

- Refractory Bricks in Liechtenstein

- Monolithic Refractories in Swaziland

- Ceramic Fiber Products in Armenia

- Monolithic Refractories in Libya

- Refractory Bricks in Japan