All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the role of steel pipes in the aerospace industry for aircraft landing gear systems?

Steel pipes play a crucial role in the aerospace industry for aircraft landing gear systems. They are used to connect various components of the landing gear system, providing structural support and ensuring efficient transfer of hydraulic fluids and gases. Steel pipes are known for their high strength and durability, enabling them to withstand the extreme conditions experienced during landings and takeoffs. Additionally, they help maintain the integrity of the landing gear system by facilitating the smooth operation of components such as actuators, brakes, and shock absorbers. Overall, steel pipes are essential in ensuring the safe and reliable functioning of aircraft landing gear systems in the aerospace industry.

What is the impact of water hammer in steel pipelines, and how can it be controlled?

Water hammer in steel pipelines refers to the sudden increase in pressure caused by the rapid acceleration or deceleration of water flow, leading to potentially damaging effects. The impact of water hammer can result in pipe bursts, joint failures, and structural damage to the pipeline system. Additionally, it can lead to excessive noise, vibrations, and increased maintenance costs.

To control water hammer in steel pipelines, several measures can be implemented. First, installing air chambers or surge tanks at strategic points along the pipeline can absorb the excess pressure and prevent its propagation. Secondly, using surge relief valves can release the excess pressure gradually, safeguarding the pipeline from potential damage. Additionally, implementing check valves or non-return valves can prevent the reversal of water flow, minimizing the occurrence of water hammer. Proper design and layout of the pipeline, including gradual changes in pipe diameter and the use of throttling devices, can also help to control water hammer. Regular maintenance, inspection, and monitoring of the pipeline system can identify and address potential issues before they escalate.

What is the significance of material traceability in the production of critical steel pipes?

Material traceability is crucial in the production of critical steel pipes because it ensures that the materials used meet the required specifications and standards. By tracing the origin and history of the materials, manufacturers can verify their quality, composition, and performance characteristics. This helps in preventing the use of substandard or counterfeit materials, which could compromise the integrity and safety of the steel pipes. Furthermore, material traceability enables effective quality control, facilitates efficient recalls or investigations in case of defects or failures, and ensures compliance with regulatory requirements. Overall, material traceability plays a vital role in ensuring the reliability and performance of critical steel pipes in various industries such as oil and gas, construction, and infrastructure.

How are steel pipes classified based on their thickness?

Steel pipes are classified based on their thickness into various categories such as schedule, nominal pipe size, and wall thickness.

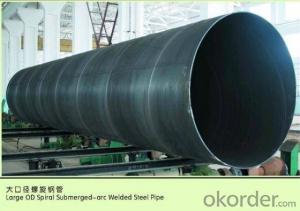

Wholesale Steel Pipes from supplier in Sudan

Whether you are involved in construction, infrastructure development, oil and gas, or any other industry requiring Steel Pipes, we have the resources and capabilities to meet your specific needs. We offer a wide range of Steel Pipes products, including seamless pipes, welded pipes, galvanized pipes, and more.

Our dedicated team of sales professionals is committed to providing outstanding customer service. We understand the importance of timely and accurate quotations, and we strive to deliver competitive pricing for our products. Our technical support team is also available to assist you with any technical inquiries or challenges you may encounter during your projects.

As a subsidiary of CNBM, we have the backing of a Fortune Global 500 company. This allows us to leverage our global network and resources to provide comprehensive procurement solutions for Steel Pipes in Sudan. We have established strong relationships with manufacturers and suppliers worldwide, ensuring that we can source high-quality products at competitive prices.

With our years of experience in the Sudanese market, we have gained valuable insights and expertise. We understand the local regulations, market trends, and project requirements, enabling us to provide tailored solutions for your projects. Whether you are looking for a specific type of Steel Pipe or need assistance with logistics and delivery, we have the knowledge and capabilities to support you every step of the way.

In summary, as a leading supplier of Steel Pipes in Sudan, we offer comprehensive procurement solutions, sales expertise, competitive pricing, and technical support. Partner with us for your Steel Pipes needs and experience the benefits of our extensive product portfolio and market experience. Contact us today to discuss your requirements and let us assist you in achieving your project goals.

Our dedicated team of sales professionals is committed to providing outstanding customer service. We understand the importance of timely and accurate quotations, and we strive to deliver competitive pricing for our products. Our technical support team is also available to assist you with any technical inquiries or challenges you may encounter during your projects.

As a subsidiary of CNBM, we have the backing of a Fortune Global 500 company. This allows us to leverage our global network and resources to provide comprehensive procurement solutions for Steel Pipes in Sudan. We have established strong relationships with manufacturers and suppliers worldwide, ensuring that we can source high-quality products at competitive prices.

With our years of experience in the Sudanese market, we have gained valuable insights and expertise. We understand the local regulations, market trends, and project requirements, enabling us to provide tailored solutions for your projects. Whether you are looking for a specific type of Steel Pipe or need assistance with logistics and delivery, we have the knowledge and capabilities to support you every step of the way.

In summary, as a leading supplier of Steel Pipes in Sudan, we offer comprehensive procurement solutions, sales expertise, competitive pricing, and technical support. Partner with us for your Steel Pipes needs and experience the benefits of our extensive product portfolio and market experience. Contact us today to discuss your requirements and let us assist you in achieving your project goals.