All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

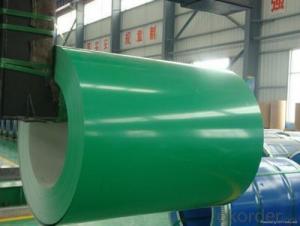

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the environmental impacts of steel coil production and disposal?

The environmental impacts of steel coil production and disposal are significant. In terms of production, the extraction and processing of raw materials, such as iron ore and coal, contribute to deforestation, habitat destruction, and water pollution. The manufacturing process itself involves high energy consumption and emits greenhouse gases, contributing to climate change.

The disposal of steel coils also poses challenges. Improper disposal can lead to soil and water contamination due to the release of heavy metals and other toxic substances used in the production process. Additionally, steel coils are non-biodegradable, adding to the burden of waste management and landfill usage.

To mitigate these environmental impacts, it is crucial to adopt sustainable practices throughout the steel coil production and disposal life cycle. This includes promoting recycling and reuse of steel, implementing cleaner production technologies, reducing energy consumption, and ensuring proper waste management and disposal methods.

How are steel coils tested for their heat resistance in the production of industrial furnaces?

Steel coils are tested for their heat resistance in the production of industrial furnaces through a process called heat treatment. This involves subjecting the coils to high temperatures for a specific period of time, simulating the conditions they would encounter in the furnace. The coils are then checked for any signs of deformation, warping, or damage, indicating their ability to withstand the heat.

What is the impact of coil temperature variations during processing?

Coil temperature variations during processing can have several impacts. Firstly, it can affect the quality of the final product. Temperature fluctuations can cause variations in material properties, such as hardness or tensile strength, which can compromise the performance or durability of the product. Secondly, it can affect the efficiency of the processing equipment. Fluctuations in coil temperature can lead to inconsistent heat transfer, affecting the processing time and energy consumption. Lastly, it can also impact the overall production yield. Temperature variations can result in dimensional changes or distortion in the coil, leading to scrap or rework. Therefore, controlling and maintaining consistent coil temperature during processing is crucial for ensuring product quality, process efficiency, and cost-effectiveness.

Wholesale Steel Coils from supplier in Sudan

We understand the unique requirements of the Sudanese market and strive to meet them effectively. Our team of experienced professionals is dedicated to delivering superior customer service and ensuring your satisfaction.

Whether you need hot-rolled steel coils, cold-rolled steel coils, or galvanized steel coils, we have a wide selection to cater to your specific needs. Our Steel Coils products are sourced from reputable manufacturers, ensuring top quality and reliability.

In addition to our sales services, we offer competitive quotations to help you make informed decisions and optimize your procurement process. Our technical support team is always available to assist you with any questions or concerns you may have, providing timely and accurate solutions.

As a subsidiary of CNBM, we benefit from the resources and expertise of a Fortune Global 500 company. This enables us to offer you a seamless procurement experience, with efficient logistics and reliable supply chain management.

Partner with us for your Steel Coils procurement needs in Sudan and experience the difference of working with a trusted and reliable supplier. Contact us today for more information or to request a quotation.

Whether you need hot-rolled steel coils, cold-rolled steel coils, or galvanized steel coils, we have a wide selection to cater to your specific needs. Our Steel Coils products are sourced from reputable manufacturers, ensuring top quality and reliability.

In addition to our sales services, we offer competitive quotations to help you make informed decisions and optimize your procurement process. Our technical support team is always available to assist you with any questions or concerns you may have, providing timely and accurate solutions.

As a subsidiary of CNBM, we benefit from the resources and expertise of a Fortune Global 500 company. This enables us to offer you a seamless procurement experience, with efficient logistics and reliable supply chain management.

Partner with us for your Steel Coils procurement needs in Sudan and experience the difference of working with a trusted and reliable supplier. Contact us today for more information or to request a quotation.