All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

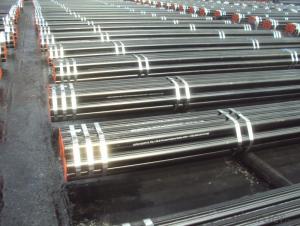

- - Seamless Steel Pipe

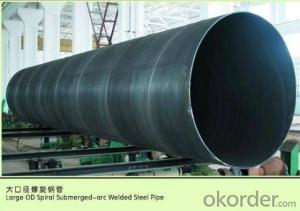

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are steel pipes employed in the automotive industry for fuel storage and delivery systems?

Steel pipes are commonly used in the automotive industry for fuel storage and delivery systems due to their high strength and durability. These pipes are employed to transport fuel from the storage tank to the engine, ensuring a reliable and efficient fuel supply. Steel pipes are resistant to corrosion and can withstand high pressure and temperature, making them ideal for safely carrying and delivering fuel in vehicles.

How does the diameter of a steel pipe impact its flow capacity and pressure ratings?

The diameter of a steel pipe directly affects its flow capacity and pressure ratings. A larger diameter allows for a higher flow capacity, as it provides a larger cross-sectional area for the fluid to flow through. This results in reduced friction and pressure drop, allowing for a greater volume of fluid to pass through the pipe. In terms of pressure ratings, a larger diameter pipe can handle higher pressures as it distributes the force over a larger surface area, reducing the stress on the pipe walls. Conversely, a smaller diameter pipe restricts the flow and can result in higher pressure drops and reduced flow capacity.

What are the design considerations for high-pressure steel pipes used in hydraulic systems?

Some design considerations for high-pressure steel pipes used in hydraulic systems include selecting the appropriate material with high tensile strength and resistance to corrosion, ensuring proper wall thickness to withstand the high pressure, incorporating seamless construction to prevent weak points, and implementing proper fittings and connections to ensure leak-free operation. Additionally, the pipes should be designed to withstand extreme temperatures and vibrations, and measures should be taken to prevent fatigue failure and maintain structural integrity over time.

What is the role of steel pipes in the manufacturing of consumer goods?

Steel pipes play a crucial role in the manufacturing of consumer goods by providing a reliable and durable material for various applications. They are used for transporting fluids, gases, and other materials within the manufacturing processes. Additionally, steel pipes are often utilized in the construction of machinery and equipment used in the production of consumer goods. Their strength, flexibility, and resistance to corrosion make them an essential component in ensuring the efficiency and longevity of manufacturing processes, ultimately contributing to the production of high-quality consumer goods.

Wholesale Steel Pipes from supplier in Panama

Whether you require steel pipes for construction, infrastructure, or industrial applications, our team is dedicated to meeting your specific needs. We offer a wide variety of steel pipe types, including seamless, welded, galvanized, and coated pipes, in various sizes and specifications.

Our sales team is highly knowledgeable and can assist you in selecting the right steel pipes for your project. We are committed to providing competitive prices and timely delivery, ensuring that your requirements are met efficiently.

Additionally, our technical support team is available to provide expert advice and assistance throughout the procurement process. We can help with product selection, material specifications, and any technical queries you may have.

As a subsidiary of CNBM, we have access to a vast global network of suppliers and manufacturers. This allows us to source high-quality steel pipes from reliable and certified suppliers, ensuring that our products meet international standards and regulations.

With years of experience in the Panamanian market, we have developed strong relationships with local suppliers and contractors. This enables us to provide valuable insights into the local industry, including market trends, regulations, and project requirements.

At CNBM, we are committed to providing comprehensive and reliable services for steel pipe procurement in Panama. Contact us today for sales inquiries, quotations, or technical support, and let us be your trusted partner for all your steel pipe needs.

Our sales team is highly knowledgeable and can assist you in selecting the right steel pipes for your project. We are committed to providing competitive prices and timely delivery, ensuring that your requirements are met efficiently.

Additionally, our technical support team is available to provide expert advice and assistance throughout the procurement process. We can help with product selection, material specifications, and any technical queries you may have.

As a subsidiary of CNBM, we have access to a vast global network of suppliers and manufacturers. This allows us to source high-quality steel pipes from reliable and certified suppliers, ensuring that our products meet international standards and regulations.

With years of experience in the Panamanian market, we have developed strong relationships with local suppliers and contractors. This enables us to provide valuable insights into the local industry, including market trends, regulations, and project requirements.

At CNBM, we are committed to providing comprehensive and reliable services for steel pipe procurement in Panama. Contact us today for sales inquiries, quotations, or technical support, and let us be your trusted partner for all your steel pipe needs.