All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the main factors that affect the formability of electrolytic tinplate coil at low temperatures?

The main factors that affect the formability of electrolytic tinplate coil at low temperatures include the composition of the tinplate, the thickness of the tin coating, the temperature at which the tinplate is formed, and the strain rate at which it is subjected to during the forming process. Additionally, the presence of impurities or defects in the tin coating can also impact its formability.

How does electrolytic tinplate coil perform in terms of moldability and formability?

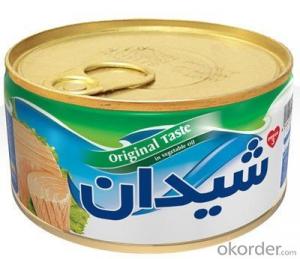

Electrolytic tinplate coil exhibits excellent moldability and formability due to its unique manufacturing process. The tin coating on the steel base enhances its ductility and allows for easy shaping and forming into various intricate designs. This makes electrolytic tinplate coil a preferred choice for packaging materials, such as cans and containers, as it can be easily molded into desired shapes without losing its structural integrity.

How does electrolytic tinplate coil compare to other packaging materials?

Electrolytic tinplate coil offers several advantages compared to other packaging materials. Firstly, its excellent corrosion resistance ensures the preservation of the product's quality and extends its shelf life. Additionally, tinplate provides an airtight seal, preventing any external factors from contaminating the product. Moreover, its high formability allows for various packaging design options, making it suitable for a wide range of products. Lastly, tinplate is recyclable, making it an eco-friendly choice in packaging materials. Overall, electrolytic tinplate coil outperforms other packaging materials in terms of durability, product protection, versatility, and sustainability.

Can electrolytic tinplate coil be painted or coated?

Yes, electrolytic tinplate coil can be painted or coated. The smooth and uniform surface of the tinplate allows for effective application of paint or coating materials, providing protection and enhancing its appearance.

What are the common surface treatments applied to electrolytic tinplate coil?

The common surface treatments applied to electrolytic tinplate coil include tin plating, chromate coating, lacquering, and passivation.

Wholesale Electrolytic Tinplate Coil from supplier in Panama

Our Electrolytic Tinplate Coils are made from high-quality materials and meet international standards for durability and performance. We offer various sizes, thicknesses, and finishes to meet the specific requirements of our clients in Panama. Whether you need Electrolytic Tinplate Coils for packaging, canning, or other industrial applications, we have the right solution for you.

As a reputable supplier, we prioritize customer satisfaction and strive to exceed our clients' expectations. Our dedicated sales team is available to assist you with any inquiries, provide competitive quotations, and ensure a smooth ordering process. We also offer technical support to help you choose the right Electrolytic Tinplate Coil product for your specific needs and provide guidance on installation and maintenance.

Being a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources, advanced technology, and a strong supply chain. This allows us to deliver top-quality products consistently and efficiently. We understand the importance of timely delivery and offer flexible shipping options to meet your project deadlines.

With our extensive market experience and knowledge of the Panama market, we can provide valuable insights and expertise to enhance the success of your projects. Whether you are a small business or a large corporation, we are committed to building long-term partnerships based on trust, reliability, and mutual growth.

Contact us today to discuss your Electrolytic Tinplate Coil requirements in Panama and experience the difference of working with a reputable supplier who puts your needs first.

As a reputable supplier, we prioritize customer satisfaction and strive to exceed our clients' expectations. Our dedicated sales team is available to assist you with any inquiries, provide competitive quotations, and ensure a smooth ordering process. We also offer technical support to help you choose the right Electrolytic Tinplate Coil product for your specific needs and provide guidance on installation and maintenance.

Being a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources, advanced technology, and a strong supply chain. This allows us to deliver top-quality products consistently and efficiently. We understand the importance of timely delivery and offer flexible shipping options to meet your project deadlines.

With our extensive market experience and knowledge of the Panama market, we can provide valuable insights and expertise to enhance the success of your projects. Whether you are a small business or a large corporation, we are committed to building long-term partnerships based on trust, reliability, and mutual growth.

Contact us today to discuss your Electrolytic Tinplate Coil requirements in Panama and experience the difference of working with a reputable supplier who puts your needs first.