All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

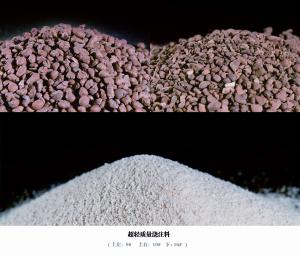

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How do monolithic refractories perform in shaping applications?

Monolithic refractories perform exceptionally well in shaping applications due to their versatility and ability to be molded into complex shapes. They can be easily formed and installed, providing a seamless and efficient lining for various industrial equipment such as furnaces, kilns, and reactors. Their high heat resistance, strength, and thermal shock resistance make them ideal for shaping applications where temperature fluctuations and mechanical stress are common. Additionally, monolithic refractories offer excellent chemical resistance, ensuring long-lasting performance even in corrosive environments.

How do monolithic refractories contribute to improving safety in industrial environments?

Monolithic refractories play a crucial role in improving safety in industrial environments by providing high thermal insulation, resistance to chemical attacks, and enhanced structural stability. These refractories offer superior heat resistance, reducing the risk of thermal accidents and ensuring the safety of personnel working in high-temperature environments. Additionally, their chemical resistance properties protect against corrosive substances, preventing accidents caused by chemical reactions. Moreover, their structural stability and ability to withstand mechanical stresses enhance the overall safety of industrial operations by minimizing the chances of refractory failure and subsequent accidents.

How do monolithic refractories provide structural integrity?

Monolithic refractories provide structural integrity by forming a strong and cohesive bond when heated, allowing them to withstand high temperatures and resist thermal shocks. They have a single, continuous structure without any joints or seams, which eliminates potential weak points. This enables them to maintain their shape and stability under extreme conditions, ensuring the structural integrity of the refractory lining.

Are monolithic refractories suitable for use in incinerators?

Yes, monolithic refractories are suitable for use in incinerators. Monolithic refractories offer excellent resistance to high temperatures, thermal shock, and chemical attack, making them ideal for lining the combustion chambers and other high-temperature areas of incinerators. Their versatility and ease of installation also make them a preferred choice for incinerator applications.

How do monolithic refractories handle gas flow?

Monolithic refractories handle gas flow by forming a dense and continuous lining that effectively seals against gas leakage. This lining is created by pouring or gunning the refractory material in place, allowing for a seamless and uniform structure. Additionally, monolithic refractories can be designed to have low porosity, high thermal conductivity, and good resistance to thermal shock, which further enhances their ability to handle gas flow.

Wholesale Monolithic Refractories from supplier in Mexico

Our company is a leading supplier of Monolithic Refractories in Mexico. With a wide range of products and services, we are well-equipped to meet all your Monolithic Refractories procurement needs. As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and expertise to provide top-notch sales, quotations, and technical support services.

Our team has extensive knowledge of the local industry, gained through years of market development in Mexico. This allows us to offer insightful guidance and support for your projects, ensuring that you get the right Monolithic Refractories for your specific requirements. Whether you need refractories for industrial applications or construction projects, we have the solutions and experience to meet your needs.

Customer satisfaction is our top priority, and we are committed to delivering exceptional service at every step. Our team will assist you with product selection and provide after-sales support to ensure your success. With our reliable supply chain network, competitive pricing, and high-quality Monolithic Refractories, we aim to be your trusted partner for all your refractory needs in Mexico.

Choose us as your Monolithic Refractories supplier in Mexico and benefit from our extensive product range, technical expertise, and customer-centric approach. Contact us today to discuss your requirements and discover how we can support your projects in Mexico.

Our team has extensive knowledge of the local industry, gained through years of market development in Mexico. This allows us to offer insightful guidance and support for your projects, ensuring that you get the right Monolithic Refractories for your specific requirements. Whether you need refractories for industrial applications or construction projects, we have the solutions and experience to meet your needs.

Customer satisfaction is our top priority, and we are committed to delivering exceptional service at every step. Our team will assist you with product selection and provide after-sales support to ensure your success. With our reliable supply chain network, competitive pricing, and high-quality Monolithic Refractories, we aim to be your trusted partner for all your refractory needs in Mexico.

Choose us as your Monolithic Refractories supplier in Mexico and benefit from our extensive product range, technical expertise, and customer-centric approach. Contact us today to discuss your requirements and discover how we can support your projects in Mexico.

Hot Search

- Monolithic Refractories in Lebanon

- Ceramic Fiber Products in Slovakia

- Refractory Bricks in Niger

- Raw Materials For Refractory in Venezuela

- Raw Materials For Refractory in Egypt

- Refractory Bricks in Gabon

- Refractory Bricks in Vanuatu

- Raw Materials For Refractory in Spain

- Refractory Bricks in Bolivia

- Refractory Bricks in Palestine