All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How can aluminum profiles contribute to sustainable water and wastewater treatment facilities?

Aluminum profiles can contribute to sustainable water and wastewater treatment facilities in several ways. Firstly, aluminum profiles are lightweight and corrosion-resistant, making them ideal for constructing durable and long-lasting infrastructure in these facilities. This ensures that the structures remain functional and efficient over time, reducing the need for frequent repairs or replacements.

Additionally, aluminum profiles have excellent energy efficiency properties. They can be used to create energy-efficient equipment and components, such as pumps, valves, and filtration systems. This helps to minimize energy consumption and reduce the carbon footprint of water and wastewater treatment facilities.

Furthermore, aluminum is a highly recyclable material, meaning that aluminum profiles can be recycled and reused at the end of their lifespan. By integrating recycling programs into these facilities, aluminum profiles can be diverted from landfill and contribute to a circular economy. This not only reduces waste but also conserves natural resources and reduces the environmental impact associated with aluminum production.

Overall, the utilization of aluminum profiles in water and wastewater treatment facilities promotes sustainability by providing durable infrastructure, energy-efficient solutions, and opportunities for recycling and resource conservation.

How do you calculate the structural integrity and load-bearing capacity of aluminum profile-based structures?

To calculate the structural integrity and load-bearing capacity of aluminum profile-based structures, various factors need to be considered. Firstly, the specific properties of the aluminum profile, such as its dimensions, material strength, and section modulus, are evaluated. These characteristics provide insight into the structural behavior and resistance to external forces. Secondly, the applied loads, such as static or dynamic forces, need to be determined accurately. This involves analyzing the expected loads that the structure will experience during its intended use or considering worst-case scenarios. Finally, utilizing engineering principles and mathematical models, calculations are performed to assess the stress and strain distribution within the aluminum profile. These calculations typically involve concepts like bending, torsion, and axial loading. By comparing the calculated stress values to the allowable stress limits determined by industry standards and codes, the structural integrity and load-bearing capacity of the aluminum profile-based structure can be evaluated. It is important to consult with experienced structural engineers or utilize specialized software to ensure accurate calculations and to account for any specific design considerations.

How do you protect aluminum profiles in aggressive chemical environments?

One way to protect aluminum profiles in aggressive chemical environments is by applying a protective coating or finish. This can help create a barrier between the aluminum surface and the chemicals, preventing corrosion and damage. Additionally, using suitable alloys or treatments during the manufacturing process can enhance the profile's resistance to chemical exposure.

Wholesale Aluminum Profiles from supplier in Mexico

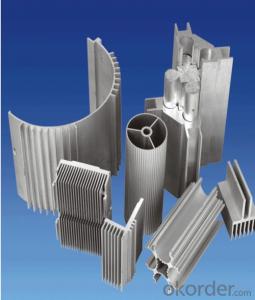

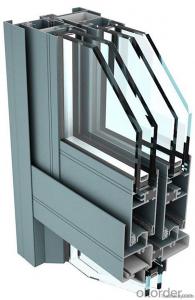

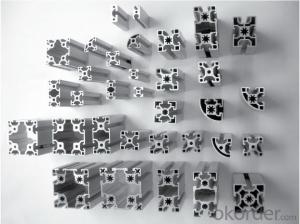

Our team of professionals is dedicated to delivering high-quality Aluminum Profiles that meet the specific needs and requirements of our customers in Mexico. We offer a wide range of profiles, including standard shapes, customized designs, and special finishes.

In addition to supplying Aluminum Profiles, we also provide sales support, including detailed product information, pricing, and delivery options. Our experienced sales team is ready to assist you with any questions or concerns you may have.

We understand that technical support is crucial for successful project implementation. That's why we offer comprehensive technical support services to ensure that your Aluminum Profiles are installed and used correctly. Our technical team is trained to provide guidance on installation, maintenance, and troubleshooting.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and expertise to offer convenient one-stop procurement services. This means that you can rely on us to handle all aspects of your Aluminum Profiles procurement, from sourcing and logistics to after-sales service.

Our years of market development experience in Mexico have given us valuable insights and expertise in the industry. We are committed to providing our customers with the best possible solutions for their projects. Whether you need Aluminum Profiles for construction, manufacturing, or any other application, we have the knowledge and products to meet your requirements.

Choose us as your trusted supplier of Aluminum Profiles in Mexico and experience our commitment to quality, reliability, and customer satisfaction. Contact us today for sales, quotes, and technical support services.

In addition to supplying Aluminum Profiles, we also provide sales support, including detailed product information, pricing, and delivery options. Our experienced sales team is ready to assist you with any questions or concerns you may have.

We understand that technical support is crucial for successful project implementation. That's why we offer comprehensive technical support services to ensure that your Aluminum Profiles are installed and used correctly. Our technical team is trained to provide guidance on installation, maintenance, and troubleshooting.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and expertise to offer convenient one-stop procurement services. This means that you can rely on us to handle all aspects of your Aluminum Profiles procurement, from sourcing and logistics to after-sales service.

Our years of market development experience in Mexico have given us valuable insights and expertise in the industry. We are committed to providing our customers with the best possible solutions for their projects. Whether you need Aluminum Profiles for construction, manufacturing, or any other application, we have the knowledge and products to meet your requirements.

Choose us as your trusted supplier of Aluminum Profiles in Mexico and experience our commitment to quality, reliability, and customer satisfaction. Contact us today for sales, quotes, and technical support services.