All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the different bending and shaping methods for aluminum profiles, and when are they used?

There are several bending and shaping methods for aluminum profiles, including cold bending, hot bending, roll forming, extrusion, and hydroforming.

Cold bending is commonly used for simple bends and curves, where the aluminum profile is bent using manual or mechanical methods without applying heat.

Hot bending involves heating the aluminum profile to a specific temperature and then bending it using specialized equipment. This method is suitable for complex and precise bends.

Roll forming is a continuous process where aluminum profiles are passed through a series of rollers to shape them into desired profiles. This method is often used for producing long, uniform shapes with consistent cross-sections.

Extrusion is a common method used to shape aluminum profiles by forcing heated aluminum through a die to create specific cross-sectional shapes. It is widely used for producing profiles with complex geometries and precise dimensions.

Hydroforming involves using high-pressure fluid to shape the aluminum profile by applying pressure from the inside. This method is suitable for producing complex shapes and allows for greater design flexibility.

The choice of bending and shaping method for aluminum profiles depends on factors like the complexity of the desired shape, the level of precision required, and the production volume.

How do you ensure the compatibility of accessories and connectors with aluminum profiles?

To ensure the compatibility of accessories and connectors with aluminum profiles, it is essential to consider a few factors. Firstly, it is crucial to select accessories and connectors specifically designed for use with aluminum profiles. This ensures that they are manufactured to fit and work seamlessly with the profile system. Secondly, thorough planning and measurement of the profile dimensions, including slot sizes and hole patterns, will help ensure proper compatibility. Additionally, consulting the manufacturer's guidelines and documentation can provide valuable information on compatible accessories and connectors, ensuring a successful integration with aluminum profiles.

What are the considerations for using aluminum profiles in the medical equipment industry?

There are several considerations when using aluminum profiles in the medical equipment industry. Firstly, aluminum is lightweight and has high strength, making it ideal for creating portable and easily maneuverable medical devices. Additionally, aluminum is corrosion-resistant, which is crucial in medical settings where frequent sterilization and cleaning are necessary. The material is also non-toxic and non-magnetic, ensuring patient safety and compatibility with medical imaging equipment. Moreover, aluminum profiles can be easily customized and fabricated to meet specific design requirements, allowing for efficient production and assembly of medical equipment. Lastly, aluminum is a sustainable and recyclable material, aligning with the industry's growing focus on environmental consciousness.

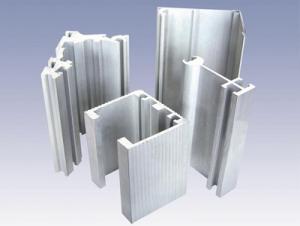

Wholesale Aluminum Profiles from supplier in Malta

Our team of experts is dedicated to understanding your specific requirements and recommending the most suitable Aluminum Profiles products for your projects. Whether you need Aluminum Profiles for construction, industrial, or architectural applications, we have a wide range of options to choose from.

We strive to provide exceptional customer service and ensure timely delivery of our products. Our sales team is well-trained and equipped with the necessary knowledge to assist you in selecting the right Aluminum Profiles for your projects. We also offer technical support services to help you with any installation or usage queries.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and manufacturers. This allows us to offer competitive prices and ensure high-quality products for our customers in Malta.

We understand the importance of delivering reliable and durable Aluminum Profiles for your projects. That is why we only work with trusted suppliers and manufacturers who meet our stringent quality standards.

With our profound market knowledge and expertise in Aluminum Profiles, we can add value to your projects by providing valuable insights and recommendations. We are committed to building long-term partnerships with our clients and strive to exceed their expectations.

Contact us today to discuss your Aluminum Profiles requirements, and let us be your trusted supplier in Malta.

We strive to provide exceptional customer service and ensure timely delivery of our products. Our sales team is well-trained and equipped with the necessary knowledge to assist you in selecting the right Aluminum Profiles for your projects. We also offer technical support services to help you with any installation or usage queries.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and manufacturers. This allows us to offer competitive prices and ensure high-quality products for our customers in Malta.

We understand the importance of delivering reliable and durable Aluminum Profiles for your projects. That is why we only work with trusted suppliers and manufacturers who meet our stringent quality standards.

With our profound market knowledge and expertise in Aluminum Profiles, we can add value to your projects by providing valuable insights and recommendations. We are committed to building long-term partnerships with our clients and strive to exceed their expectations.

Contact us today to discuss your Aluminum Profiles requirements, and let us be your trusted supplier in Malta.