All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the maximum diameter of a welded steel pipe that can be produced?

The maximum diameter of a welded steel pipe that can be produced depends on various factors, such as the manufacturing capabilities, equipment, and specific requirements. However, large diameter welded steel pipes can be produced up to approximately 120 inches (10 feet) or even more in certain cases.

Can welded steel pipes be used for bicycle frames?

Yes, welded steel pipes can be used for bicycle frames. Steel is a commonly used material for bicycle frames due to its strength, durability, and affordability. Welded steel pipes provide a strong and rigid structure, allowing for a stable and reliable bike frame.

How do you calculate the required coating thickness for a welded steel pipe?

The required coating thickness for a welded steel pipe is typically calculated based on factors such as the intended application, environmental conditions, and desired level of corrosion protection. Various industry standards and guidelines provide formulas and procedures to determine the appropriate coating thickness. These calculations often consider factors like pipe diameter, expected service life, coating type, and coating performance characteristics. It is important to consult relevant standards and experts in the field to accurately calculate the required coating thickness for a specific welded steel pipe application.

Can welded steel pipes be used for oil refinery applications?

Yes, welded steel pipes can be used for oil refinery applications. They are commonly used for transporting various fluids, including oil, in refinery processes. Welded steel pipes offer durability, strength, and resistance to high temperatures and pressures, making them suitable for these demanding applications.

What are the disadvantages of using welded steel pipe?

Some potential disadvantages of using welded steel pipe include its susceptibility to corrosion, limited flexibility, and higher cost compared to other pipe materials. Welded steel pipe may require additional protective coatings or treatments to prevent rust and corrosion, especially in harsh environments. It may also have limited flexibility and be less suitable for applications that require bending or maneuverability. Additionally, the production process of welded steel pipe can be more expensive than other pipe materials, resulting in higher upfront costs.

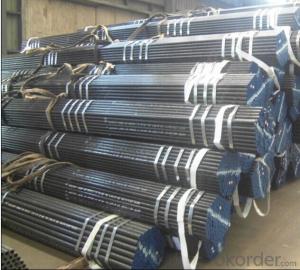

Wholesale Welded Steel Pipe from supplier in India

We understand the unique requirements of the Indian market and strive to deliver high-quality Welded Steel Pipes that meet industry standards and customer specifications. Our team of experts is knowledgeable about the latest developments in the steel industry and can provide technical support and guidance throughout the procurement process.

Whether you need Welded Steel Pipes for industrial applications, infrastructure projects, or construction purposes, we have the products and services to meet your needs. Our Welded Steel Pipes are available in various sizes, grades, and specifications to cater to different project requirements.

In addition to supplying Welded Steel Pipes, we also offer value-added services such as cutting, beveling, and fabrication to further customize the pipes according to your specifications. We prioritize customer satisfaction and aim to provide timely and efficient delivery of our products.

Partnering with us means gaining access to a wide range of high-quality Welded Steel Pipes, backed by the expertise and resources of a Fortune Global 500 company. We are committed to building long-term relationships with our customers and providing them with the best solutions for their Welded Steel Pipe needs in the Indian market.

Whether you need Welded Steel Pipes for industrial applications, infrastructure projects, or construction purposes, we have the products and services to meet your needs. Our Welded Steel Pipes are available in various sizes, grades, and specifications to cater to different project requirements.

In addition to supplying Welded Steel Pipes, we also offer value-added services such as cutting, beveling, and fabrication to further customize the pipes according to your specifications. We prioritize customer satisfaction and aim to provide timely and efficient delivery of our products.

Partnering with us means gaining access to a wide range of high-quality Welded Steel Pipes, backed by the expertise and resources of a Fortune Global 500 company. We are committed to building long-term relationships with our customers and providing them with the best solutions for their Welded Steel Pipe needs in the Indian market.